1.Project introduction

Vertical roller mill machines are very important in the cement plant. Along with development of variable frequency drive controlling technology, nowadays mostly asynchronous motors are driven by variable frequency driver instead of old traditional technology such as soft starter to realize automatic control and changing cement production.

Customer has below serious challenges:

1.Can’t increase cement product.

2.Grid line power factor is low.

3.High fault ratio and high maintenance costs for Slip-ring motor.

Site cement mill:

Detailed motor parameters are list as follow:

Table 1.Cement mill Motor Parameters

| Motor Model | Power | Rated Voltage | Rated Current | Rated Speed | Power Factor | Load Type |

| MAW 800L | 8000KW | 11000V | 483.4A | 994RPM | 0.89 | The cement Vertical mill |

Figure 2.The cement mill motor

2.System Configuration

Based on INVT experience on vertical roller mill variable frequency drive renovation project, INVT can supply whole solution for the customer.

INVT suggest VFD solution:

Table 2.MVD for Cement mill

| VFD Model | Power | Rated Voltage | Rated Current | Other |

| GD5000-A12500-11-D | 10000kw | 11KV | 656A | / |

Figure 3.The cement mill VFD

3.Features and Advantage

After using MV Drive, there are some major advantages as follow,

1.Increase cement product.

Table 3.Increase cement product

| Before using MVD | After using MVD | Remark | |

| Motor running speed | 994RPM | 1094RPM | Change Slip-ring motor to squirrel-cage motor |

| Cement product capacity(PSC) | 240TPH | 336TPH | |

| Increase cement product ratio | (336-240)/240=40% | ||

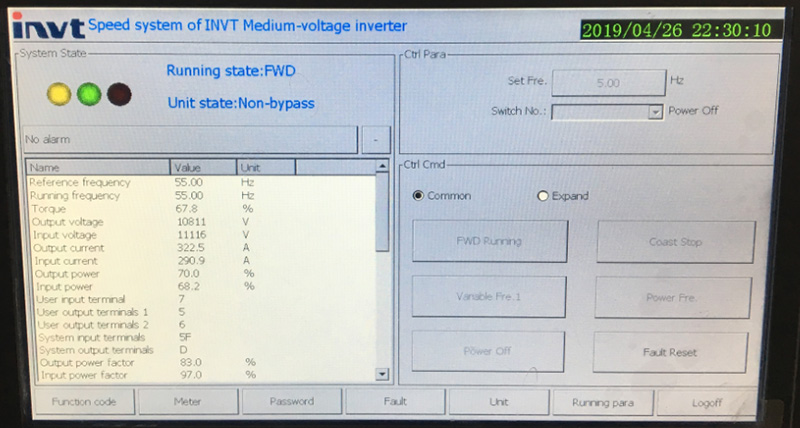

Figure 4.VFD running at 55Hz and 1094RPM

2.Increase grid line power factor.

The grid line power factor is over 0.97. So don’t need capacitor compensation device.

3.Very low torque pulse.

Low torque pulse without causing the resonance between the motor and other mechanical devices, and reducing the transmission mechanism wearing.

4.Perfect output waveform.

Output waveform is perfect, less than 2% of distortion.

5.Prolong motor working life time.

VFD can keep motor running at optimal situation.

6.Reduce maintenance costs.

4.Conclusion

Compared with original vertical roller driven method, the MVD driven method has many advantages. Especially increase cement product. The MVD system is easily controlled by CCR and the MVD running speed can automatic adjusted from 0RPM to 1094RPM. The upgraded MVD system works very well, customers are satisfied with INVT solution and INVT MVD met with customer’s requirements.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.