Abstract:

This paper mainly presents INVT EC160A intelligent integrated machine used for retrofitting of KONE elevator in India. It gives the detailed retrofitting solution for KNOE elevator and commissioning details. Engineering practice shows that INVT EC160A intelligent integrated machine has good control performance and stability on KNOE elevator.

Keywords: EC160A, KNOE elevator retrofitting, intelligent integrated machine.

I. Introduction

KONE elevator is the top 5 elevator brand in the world, and has very big market share in India. KONE has its own special control system and motor. They are not compatible with other brand control system and motor. So KONE ruled the after sales service market. Any parts broken, the end users have to go with KONE costly spare parts. So the users complain a lot but no other choice.

Now INVT has developed EC160A elevator intelligent integrated machine which can drive KONE motor and replace the whole control system. It can break the monopoly of KONE on after sales service market. EC160A elevator drive intelligent integrated machine has the following features.

Basic performance

• Resources reducing in the elevator installation, debugging, operation and management.

• Max speed: 6m/s Max floor: 64

• Intelligent network group control can control 8 elevators at the same time

• Embedded high-performance starting compensation technology of non-weighting sensor

• Advanced space vector calculation and be compatible to the encoder of AM/SM motor

• High-performance current vector control, 180% torque output at zero speed

• Low voltage emergency-rescue mode of AC220V single phase UPS, search the direction in light load

• Safety enabling hard ware input conform to EN81 standards

Special functions

• Support both serial and parallel communication.

• Hand terminal: stand-alone human-machine interface, on-line Chinese/English help system; functions of debugging management, debugging trace management, parameters uploading/downloading, computer data copying

• The hand terminal can be connected to the CAN interface in the car for convenient parameters setting

• Add TCP/IP internet module for remote debugging and control

• Support remote control of TCP/IP protocol

II. Configuration of KONE elevator

There is one lift out off service due to AMC negotiation fail.

Tab 1 Lift information

| Lift speed | 1.0 m/s |

| Capacity | 6 persons, 408KG |

| Floor | 7 floors |

| Power supply | 3phase 415V |

| Motor type | Synchronous motor |

| Rated power of motor | 3.7kW |

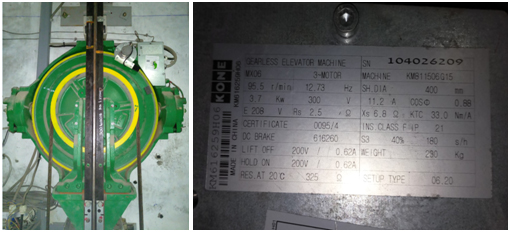

Fig 1 KONE control panel and VFD

Fig 2 KONE motor and motor nameplate

III. EC160A solution for KONE elevator retrofitting

1. EC160A electrical configuration

According to the lift configuration and the demanding functions, we provide the electrical solution as follow. Considering higher ambient temperature, one grade higher of intelligent machine rating is selected.

Tab 2 Configuration list

| Item | Model | Qty |

| EC160 integrated machine | EC160A-5R5-4 | 1 |

| Handheld operator | EC-PAD | 1 |

| Encoder | 8.5000.0000.1024.S026.0070 | 1 |

| Sensor | PF125-8DN | 1 |

| Display and calling board | 7 segment | 8 |

| Brake resistor | 50Ω/2000W | 1 |

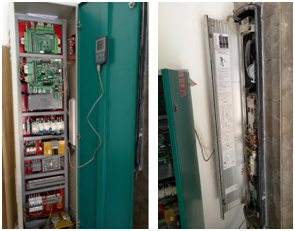

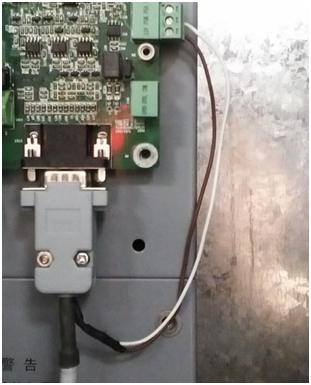

Fig 3 EC160A control panel

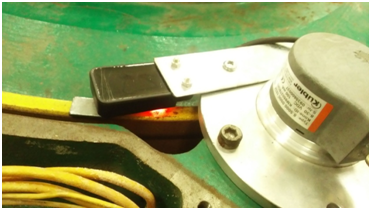

2. Encoder retrofitting

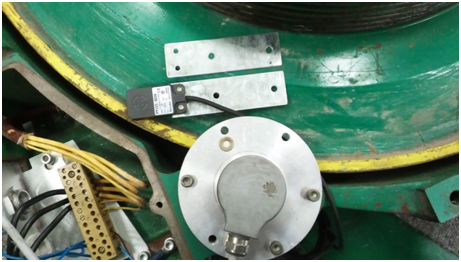

2.1 Install the encoder as showing in the below picture:

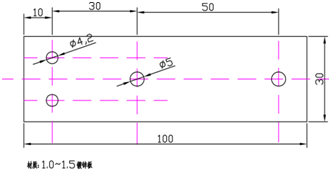

2.2 Use M3 screw to fix the sensor on the bracket, as showing in the below picture:

2.3 Use M4 screw to fix the bracket on the flange plate of the encoder. The sensor should be under the bracket near the motor wheel side as showing in the below picture, and use glue to fix the magnet:

2.4 Connect the sensor signal to EC160A SUDZ and power cable to 24+ and 24-:

2.5 Make the encoder cable connection according to the below list

| EC160A CN10(DB15) | Encoder signal | EC160A CN9 |

| 1 | B- | / |

| 5 | AA | / |

| 6 | A- | / |

| 7 | 0V | PGM |

| 8 | B+ | / |

| / | +UB | 12V |

3. EC160A parameter setting

Basic parameters setting are as follow.

| Function Code | Name | Description | Setting Value |

| P0.00 | Control mode | 1, Vector control with PG | 1 |

| P0.01 | Rated speed of the elevator | 0.100~6.00 m/s | 1.0 |

| P0.02 | Max. speed of the elevator | 0.100~P0.01 m/s | 1.0 |

| P0.03 | Max. output frequency | 10.00~400.00Hz | 12.73 |

| P0.04 | Diameter of traction sheave | 100~2000mm | 400 |

| P0.05 | Reduction ratio | 1.00~60000 | 16666 |

| P0.06 | Suspension ratio of rope | 1~8 | 2 |

| P1.00 | Increasing acc 1 | 0.001~1.000m/s3 | 0.2 |

| P1.01 | Increasing acc 2 | 0.001~1.000m/s3 | 0.2 |

| P1.02 | Acc speed | 0.001~1.000m/s2 | 0.4 |

| P1.03 | Reducing dec 1 | 0.001~1.000m/s3 | 0.2 |

| P1.04 | Reducing dec 1 | 0.001~1.000m/s3 | 0.2 |

| P1.05 | Dec speed | 0.001~1.000m/s2 | 0.4 |

| P1.06 | Door area | 0~1000mm | 100 |

| P2.00 | Motor type selection | 0: Asynchronous motor | 0 |

| P2.01 | Rated power of the motor | 0.1~150.0kW | 3.7 |

| P2.02 | Rated frequency of the motor | 3.00~400.00Hz | 12.73 |

| P2.03 | Rated speed of the motor | 1~3000rpm | 96 |

| P2.04 | Rated voltage of the motor | 0~460V | 300 |

| P2.05 | Rated current of the motor | 0.1~1000.0A | 11.2 |

| P3.00 | Encoder type selection | 0~6 | 6 |

| P3.01 | Encoder resolution | 1~10000 | 1024 |

| P3.00 | Encoder direction | 0: Forward input | 0 |

| P4.00 | ASR low speed proportional gain | 0~100 | 30 |

| P4.02 | Low speed detection filter time | 0~8 | 2 |

| P4.04 | ASR high speed proportional gain | 0~100 | 20 |

| P4.06 | High speed detection filter time | 0~8 | 2 |

| P4.08 | ACR proportional coefficient P | 0~65535 | 600 |

| P4.10 | ACR filter coefficient | 0~65535 | 64 |

| P4.09 | ACR integral coefficient I | 0~65535 | 600 |

| P5.09 | Threshold of over speed deviation | 0.1%~50.0% | 30.0 |

| P5.10 | Detection time of over speed deviation | 0.000~10.000 | 1.500 |

| A1.01 | Total floor setting | 2~64 | 5 |

| T0.04 | Brake opening delay | 0~5.000s | 0.600 |

| T0.05 | Brake closing delay | 0~5.000s | 0.600 |

| T0.07 | Direction cancel delay | 0~5.000s | 0.600 |

| T0.14 | Speed reference delay | 0~5.000s | 0.600 |

| F0.00 | High/low voltage detection | 1: only detection lower voltage | 1 |

| F0.13 | Line 2 function selection | 35: UPS output detection | 35 |

| F0.18 | Relative selection of elevator running | 1: calling below 32 floors connect to inside line | 1 |

| F0.21 | Leveling distance | 0~65535 | 100 |

| F0.22 | UPS application | 0: 220V power supply | 0 |

4. Advantages

• Intelligent integrated: EC160A is the combination of controller and inverter.

• Support dual communication methods: Serial and parallel communication.

• Simple and stable: 2 sets of CAN communication interface makes the system simple, high efficient and stable.

• Easy debugging: LCD operator with 10 rows display can show all the running state information. It makes debugging easier.

• ARD function: With single phase 220VAC UPS, EC160 can run to the nearest floor and open the door when grid power is off.

IV. Conclusion

After retrofitting by EC160A, the KONE elevator runs perfectly. The customer is very satisfied. It proofs that the monopoly can be broken. More and more customers will choice INVT EC160A to replace KONE system in future. EC160A has broad market prospects.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.