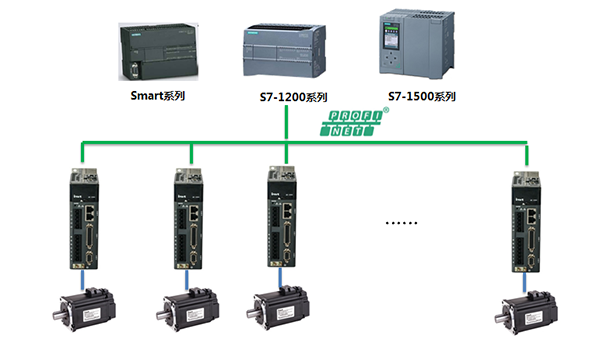

Based on its strong networking capabilities, PN communication has always played a leading role in the field of industrial automation. There are very few choices in the market for domestic servos that support PN communication.

As a leading domestic VFD industry, INVT has long developed products supporting PN communication on VFDs. With the rise of domestic servo in recent years, INVT has also successfully developed and widely applied servo drives DA200 -F0 series and DA200 -D0 series supporting PN communication in its DA200 servo platform.

INVT's servos supporting PN communication are divided into two models: Profinet IO-based -F type and Profidrive-based -D type. Both models have the same exterior but slightly different internal hardware.

The F model is flexible in development and use, and can be prepared according to the needs of the FB program adapted to the process; Based on the Profidrive protocol, the D model supports common Siemens 111, 102, 105 and other messages, and is seamlessly compatible with Siemens PLC.

INVT Profinet IO Servo(-F0 Model)

Power:0.1~55kw

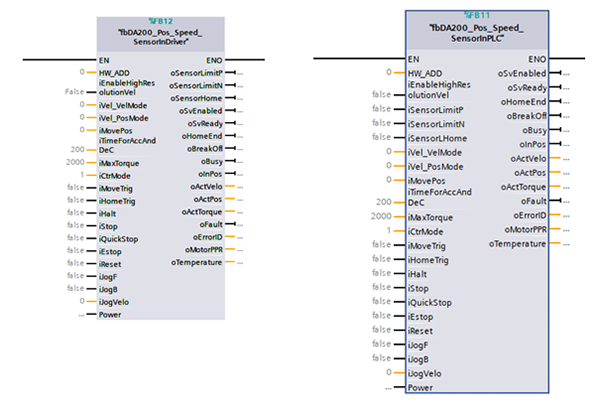

Based on PROFINET IO, the F0 model offers high application flexibility and can be programmed to realise position control, speed control, torque control as well as position-speed, position-torque and torque-speed composite control.

At the same time, INVT also provides sample programmes that can be used directly, regardless of whether the sensor is PNP or NPN, connected to a driver or to a PLC, normally open or normally closed. In addition to INVT motors, third-party explosion-proof motors, high protection grade motors, and even linear motors can be supported.

In addition, if you want to read the temperature of the drive, the sample programme has also done the corresponding function; if you want to know the drive output current, output voltage, load factor and other related data, according to the sample programme to slightly change the code can be.

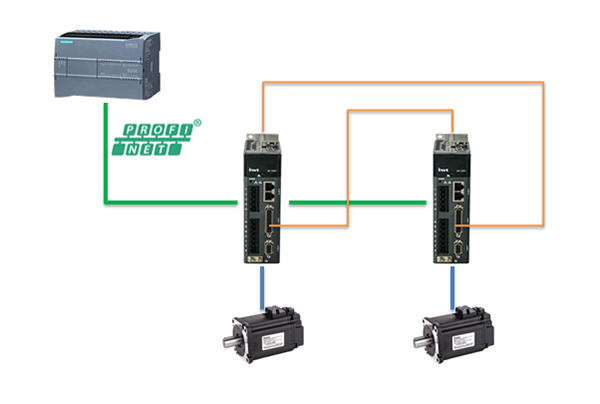

For simple linear synchronization (gantry synchronization), INVT can also provide gantry algorithm with built-in driver, even if Siemens Smart series PLC or S7-1200 series PLC is used, gantry synchronization control can be realized, compared with the use of S7-1500 series PLC, greatly reducing user costs.

Gantry algorithm built-in drive schematic

INVT Profidrive Servo(-D0 Model)

Power: 0.1~5.5kW

The D0 model is based on the Profidrive protocol and uses the Siemens isochronous synchronisation chip. In addition to the commonly used Siemens 111 telegrams to complete conventional point-to-point positioning control and Siemens 105 telegrams to complete cam synchronisation, interpolation and other complex motion control, it also supports 1, 2, 3, 5, 7, 9, 102, 110 and the additional telegram 750.

Product Applications

* Application on a pharmaceutical sorting equipment

Mainly used in hospitals, medicine vending machines for automatic pickup.

Control mode: position control

* Application on the car exchange station

In a new energy vehicle battery swap station project, torque control is used for the disassembly and assembly of the screws of the battery pack, and conventional point-to-point positioning is used for tire clamping. In order to ensure that the vehicle is not tilted during jacking, the jacking servo adopts gantry synchronous control, and the gantry algorithm is made in the drive, which saves the controller cost and simplifies the difficulty of user control.

Control modes: position, torque, gantry.

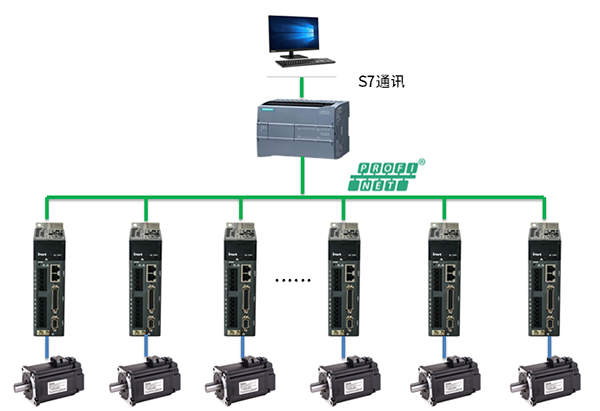

* Application in automotive parts assembly line

INVT's Profinet IO-based driver does not occupy CPU resources and can meet the needs of applications with dozens of axes.

Control modes: position, speed

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.