Abstract: The traditional hydraulic anti-shake system has a long response time delay, component loss and other issues, seriously troubling the port machine users, with the in-depth promotion of frequency control in the port machine industry, frequency anti-shake system gradually attracts the concern of majority port machine manufacturers and users, and becomes the mainstream of industry applications with its superior torque control performance and solid stability. The rail suspension anti-shake system in this article adopts INVT CHV190 inverter to overcome the lack of hydraulic anti-shake system, which has significantly weaken the spreader swing, marking another major improvement of domestic inverter application in the port machine industry.

Keywords: Port machine, track suspension, anti - shake system, torque control

Project background

Track-type gantry crane refers to rail crane, it is the the main loading and unloading equipment of wharf and freight yard. Spreader swing is easy to occur in the goods lifting process and becomes the hidden trouble that causes box hitting, So the rail crane not only includes lifting, car, truck and other components but also the anti-shake system. At present, the rail crane generally adopts hydraulic anti-shake system, although the price is cheap, but the anti-shake steel wire rope has a short life, the annual replacement of steel wire rope will increase the maintenance costs and extend the production stopping time, causing huge loss to the owners.

The frequency conversion anti-shake system has characteristics of good torque followability and strong reliability. It can quickly and obviously reduce the spreader swing in the car and lifting mechanism. It has not only improved the loading and unloading efficiency of container, but also the steel wire rope loss of rail crane.

INVT CHV190 series lifting inverter, with fully overloaded design, has characteristics of large low frequency torque, fast dynamic response, high control accuracy and reliable performance, which can really achieve the torque control and provide a perfect solution for rail crane anti-shake system.

System Overview

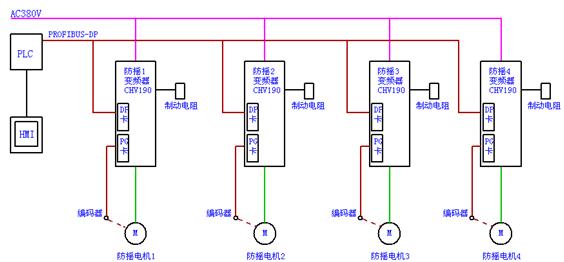

Shanghai Yangpu freight yard uses 2 sets of 45T rail cranes of Zhuhai Sanyi Port Mechine Limited Company, and each rail crane adopts frequency conversion anti-shake system and is configured with 4 sets of 15KW INVT CHV190 inverters. Send control commands and torque commands to the inverter via Siemens S7-300 PROFIBUS bus to achieve motor torque control, dynamic tension anti-shake steel wire rope. With the torque signal given by PLC, in the process of lifting and lowering container, the motor effectively pulls anti-shake steel wire rope and minimizes the spreader swing.

Each inverter is expanded with DP communication card to achieve communication between S7-300 and CHV190 DP, expanding the asynchronous PG card and collecting encoder signal to achieve closed-loop vector control.

Running effect

After commissioning, the good scene usage can meet customers’ demands, it is another successful breakthrough of INVT inverter in a new field.

Reference

"CHV190 series crane dedicated inverter manual"

"Standard for Crane Design". National standard GB / T3811 2004

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.