INTRODUCTION

A set of carts looking like a small dragon rides on an oval track with alternating ascents and descents. It serves for the joy of children and their adult parents on the occasion of various festivities or in amusement parks.

Pic. 1 Little Green Dragon

DESCRIPTION

Before the start of the attraction, the roller coaster stays on the parking sensor.

The parking sensor serves for several purposes:

-parking the set

-ride laps counter

-measurement sensor of actual roller coaster speed for correction of drives frequency (lower losses and less stress on the wheel mechanism)

After the start, the roller coaster accelerates synchronously to maximum speed by both vfd drives. Then the roller coaster is running around with inertia itself for whole ride lap.

After the roller coaster leaves the station, frequency of the drives decreases to previous calculated speed level (actual speed of the roller coaster).

Maximum frequency is applied by reaching of the speed sensor located in front of the first drive (wheel) mechanism. It accelerates the roller coaster to maximum speed.

After elapsing of set number laps following things happen:

-timing out after passing speed sensor causes the roller coaster deceleration to zero speed

-parking in reverse direction at a slow speed onto the parking sensor

-a new ride can begin after that

There are several modes with different numbers of wheels. If the roller coaster is outside the parking sensor for some reason, parking sequence can be started as following:

-slow move forward direction

-timing

-slow move reverse direction

-stopping onto parking sensor

Pic. 2 The principle of operation

CONTROL

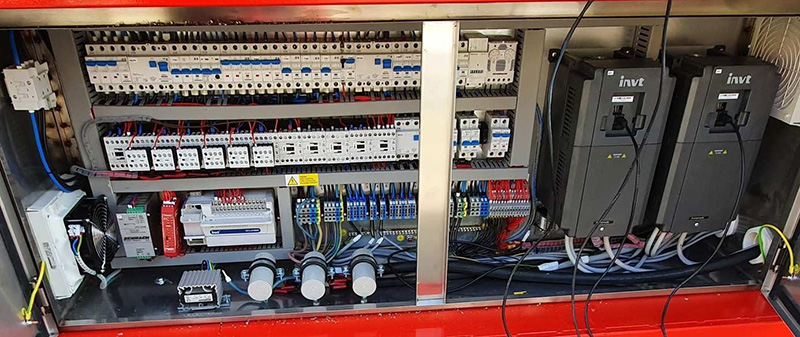

The roller coaster is controlled by INVT PLC IVC1L 2416 MAR and drive control with two GD20- 011G-4-EU drives. External braking resistors are also installed.

Drives are working as MASTER - SLAVE interconnection via analog signals.

The first drive (MASTER) takes frequency reference from PLC via MODBUS serial communication.

The second drive (SLAVE) one takes frequency reference from analog output of MASTER drive, which is monitoring its frequency reference.

Pic. 3 Electrical Cabinet

Reference: Roller coaster Little Green

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.