Summary: When we browse the web, micro-blog and WeChat will be rather baffling out some ads, but the strange thing is that some advertisements do you need, in fact these ads are not careful, this is a big data analysis and the results of the use of.

We want to travel, vacation, booking air tickets, hotel online, always easily according to the specified time and place, the star to find the right target, and can be found to the scenic area more convenient hotel accommodation, and had maxed circle of friends of the Alipay bank's credit card bills, pay bills, and big data closely connected.

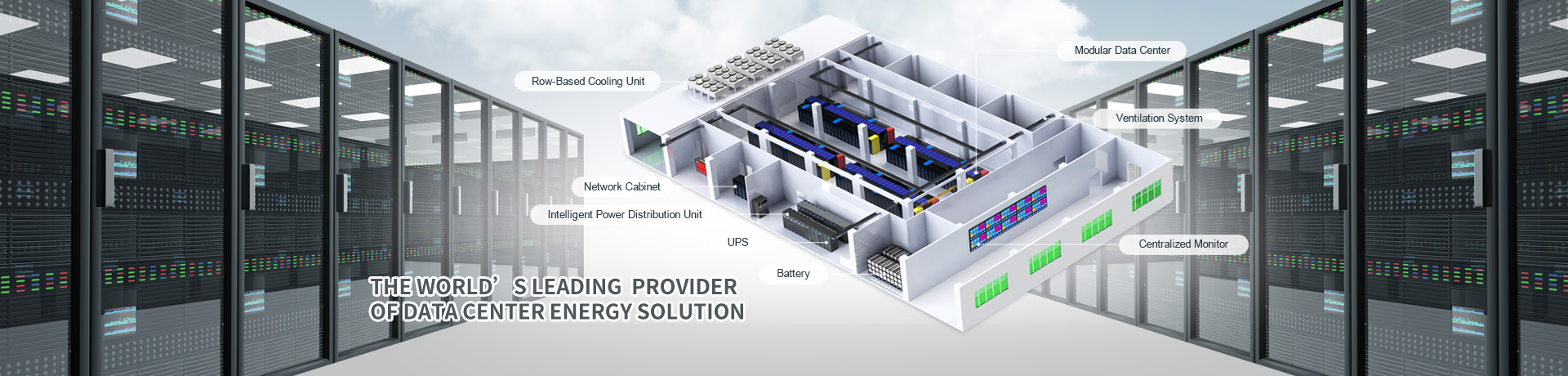

In the current data center industry in the application and rise of various big data technology, the amount of data presents a spurt of growth, as well as users of the data center business availability requirements also put forward new demands and changes. In this context, the construction of data center infrastructure is facing new challenges and opportunities, modular, intelligent, rapid expansion, flexible response, green environmental protection.

INVT modular data center infrastructure solutions

Modularization of infrastructure and Engineering

At present, the industry commonly used micro module data center is mainly used in indoor scenes, mainly by the end of the IT equipment, air conditioning, HVDC between columns and modular UPS, a micro channel cooling module products; container type data center is mainly used in outdoor scenes, including IT box, distribution box, cold box, Faxiang Chai box office, etc.. The former implements large-scale deployment, but is only used for IDC terminal devices, and lacks mobility. The latter is easy to move and flexible to build, but the scale is limited. Combining the two can build a large data center in a faster and more flexible way.

The data center of the main modules such as IT, the infrastructure (electricity, air conditioning, electricity etc.), engineering facilities (buildings, offices) according to the optimal model and construction method on the product of the standard interface, to form the pre prepared container products in the factory by the highway freight carrier, you can quickly move to the project site, and can be flexibly disassembled, built and moved to other venues recycling. In the project site, infrastructure and engineering supporting construction and deployment mode such as pile blocks, flexible construction site and construction cost are greatly reduced, and the data center construction is green construction cost are greatly reduced, and the data center construction is green.

In addition, the building structure is very simple, so the machine floor of the main building construction time can be greatly shortened, especially the frame structure and the large bay, the whole wall mosaic pattern room frame construction time is very short, large space structure and wall stitching mode not only construction progress, and building materials Recyclable use more green environmental protection, in addition to the relocation of large equipment out of the room area, is more suitable for the construction of large data center model. Because the room building structure is very simple, and large mechanical and electrical equipment mostly outside, so in the data center space utilization rate is very high, can put most of the floor space for placing the IT cabinet, so each cabinet volume ratio is very low, greatly enhance the utilization rate of the space in the room.

INVT - Tengzhi ITalent series of large integrated intelligent data center

INVT - Tengzhi ITalent series of large integrated intelligent data center

Direct / indirect multi-mode natural refrigeration

The weather conditions permit area, when the outdoor temperature is lower than the indoor, the recommended way is commonly used by direct air cooling, the initial investment is low, the system is simple, obvious energy saving effect on regional natural conditions are good. But the fresh air enters the room directly, the temperature and humidity are difficult to control, resulting in a large number of condensed water and humidifying excessive energy consumption and bad dust removing effect, not in other chemical pollutants such as sulfide and phosphide.

In order to solve these problems, can be introduced into the indirect wind heat natural cooling, indirect natural cooling is the use of a air - air heat exchanger, the low temperature outdoor air through the heat exchanger to the indoor temperature and air, avoid the pollution caused by the external air directly into the room. At the same time, the air air heat transfer efficiency is reduced, the size of the heat exchange equipment is large, and the energy saving is affected. In order to further improve energy efficiency, indirect evaporation and natural evaporation combined with direct fresh air natural cooling, wind heat transfer, natural cooling and mechanical refrigeration can be used to flexibly select working modes in different scenes.

Direct fresh air natural cooling mode

When the outdoor temperature is low and the air quality is good in winter, the outdoor fresh air and indoor hot air can be mixed and filtered and sent into the computer room, which can reduce the energy consumption of air conditioning to the greatest extent.

Natural cooling mode of indirect wind and air heat transfer

In the case of low outdoor temperature in winter, in order to avoid the air quality problems caused by direct fresh air, the heat exchange between the return air and the outdoor cold air in the heat exchanger is carried out in the heat exchanger.

Indirect evaporative natural cooling model

In the spring and autumn season, the outdoor air temperature is low, because the outdoor air temperature is not low enough, the need for high-pressure micro mist spray adiabatic evaporation refrigeration way to supplement the amount of refrigeration.

Indirect evaporation natural cooling + mechanical cooling mode

In the summer, the outdoor temperature is high, through the high-pressure micro mist spray adiabatic evaporation refrigeration to supplement refrigeration, such as indoor air temperature through the heat exchanger after cooling still does not reach the requirements of air temperature, but also need to add mechanical refrigeration.

The introduction of indirect evaporative cooling scheme no compressor running mode, using water evaporation heat exchange principle, air and air heat away room heat, energy efficiency ratio of EER up to 16, is 5 times of compression refrigeration and air conditioning machinery, energy saving compared to conventional chiller cooling rate, the annual energy saving rate of >50%. INVT recommended indirect evaporation cooling scheme combined with fresh air, wind heat, mechanical refrigeration function, flexible work mode selection in different scenarios, to enhance the overall efficiency of energy use in the room.

New energy and uninterrupted power supply combined with direct power supply and distribution.

The data center has always been a big energy consumer, so many technology giants are trying to innovate in the introduction and application of new energy technology. Solar energy is one of the most widely used green new energy sources in cities with sufficient lighting. Solar photovoltaic power generation system consists of polysilicon components, in order to save installation space, can be installed in a modular data center top components are transversely arranged, and bracket with adjustable spacing adjustable angle function, the overall stent is simple, fast installation.

Photovoltaic power generation is affected by sunlight, there is power supply instability, data center power distribution can be combined with uninterruptible power supply, power grid connection mode using multi-channel redundancy scheme to achieve flexible switching overnight maintenance. According to different application scenarios, a variety of work modes can be flexibly selected:

Model one

The power supply of the server is customized according to the main power supply, and the main power supply of the two main power supply systems is connected with the direct supply of the city power supply and the connection of the photovoltaic and uninterruptible power supply (UPS);

Mode two

The server power supply is not divided into main and standby, photovoltaic and UPS grid connected with the city power supply directly, each half of the load

Mode three

Server power supply according to the main standby, photovoltaic and urban power grid connected with the UPS two power supply one main one standby;

Mode four

The power supply of the server is not divided into main and standby. After the grid connection of PV and city power, half load is carried out with UPS.

Due to the higher reliability and efficiency of the UPS, the HVDC scheme is preferred for uninterruptible power supply (HVDC). INVT suggestions on energy saving and reliability of distribution system considering.

The scheme of distribution logic is: the power input through the rectifier, HVDC output 270Vdc, PV output by DC/DC 270Vdc input, 2 output DC Road 1 road, controlled by the monitoring module, the AC PDU in hot standby state. The output of the circuit is supplied to the cabinet. During the day, the photovoltaic panel provides 100% power supply and charging the battery, AC PDU 0% reserve; at night, HVDC provides 100% power supply cabinet, and charging the battery, AC PDU 0% reserve; when the photovoltaic panels and HVDC at the same time the fault or maintenance, AC PDU power supply 100%. In order to make full use of photovoltaic power, the peak watt value of PV system is consistent with the peak load value.

The introduction of green energy photovoltaic power generation, the use of photovoltaic new energy and HVDC DC grid, combined with direct power supply and supply of urban power supply innovation program, can ensure the system reliability on the basis of greatly reducing the distribution energy consumption.

Intelligent management

Data center re construction, light operation and maintenance is the disadvantage of most projects. The long running life of operation and maintenance in data center plays a vital role in energy saving and reliability of the system. In order to reduce human errors, and to hand to the paper, the remote intelligent INVT monitoring system to achieve the following functions:

Modular, intelligent, rapid expansion, flexible response, green energy saving has always been the theme and soul of leading the change of data center. In the modular data center on the basis of the existing and proposed solutions of INVT MDC+ data center construction of green energy saving new generation module based on, put forward a number of innovative technologies to improve energy efficiency. Through the IT and supporting (infrastructure, engineering) modular product design, direct / indirect multi mode natural cooling refrigeration technology, energy and uninterruptible power supply with power grid direct power supply technology and remote monitoring technology is expected to achieve intelligent visualization of global PUE below 1.5, to provide reference for a new generation of modular data center infrastructure infrastructure construction.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.