Abstract: INVT kinway brand MH500 series electro-hydraulic servo system is designed for injection molding machine, die-casting machine, oil press and other hydraulic equipment, it adopts high-performance vector control with the features of energy saving, precision, high efficiency and durability. MH500 series electro-hydraulic servo system has rich external expansion interface and CAN communication interface to facilitate the composition of multi-pump parallel system and achieve hydraulic control of high-flow system.

The application of INVT kinway brand hydraulic servo system in injection molding machine, it’s special for the injection molding machine oil press system, and has a great significance for reducing energy waste and improving production efficiency.

Keywords: injection molding machine, pressure compensation flow control, decoupling PQ control

1. Preface

For the plastics industry, electricity consumption is a major part of its production costs, and injection molding machine is one of the main energy consumption equipment of plastic products factory, thus reducing the energy consumption of injection molding machine and improving production efficiency have become the effective way to reduce the costs of injection industry and improve product competitiveness.

After testing, the general single traditional quantitative pump injection molding machine energy consumption and the proportion are:

Energy consumption of oil press system: 75-80%

Heating unit energy consumption: 10-15%

Cooling system energy consumption: 5-10%

Control component energy consumption: 1-5%

One part of the largest energy consumption: oil press system power consumption accounts for more than 75% of injection molding machine.

At present, the vast majority of injection molding machines are hydraulic drive injection molding machine, hydraulic drive system is driven by the motor provided by the pump. During the injection cycle, clamping, injection, holding, cooling, open mold and other processes require different pressure and flow, the pump motor is in the state of load changes.

Hydraulic system has great load changes, the traditional injection molding machine adopts quantitative pump, it cannot adjusts the output speed and power, so the excess energy can only be consumed in the baffle, oil circuit leakage, oil temperature rising. When the system needs more than the set flow and pressure, the relief valve or proportional valve will adjust the pressure flow, and this process is called high pressure throttling, resulting in energy loss as high as 40% -75%.

This has exacerbated the wear of various valves, but also caused the too high oil temperature, too large motor noise, and shorten mechanical life and so on. And usually in the design, the set capacity of user pump motor is much higher than the actual needs, there exists the phenomenon of "big horse pulls a small carriage ", resulting in a lot of energy waste.

Therefore, the application of INVT kinway electro-hydraulic servo system in the injection molding machine is mainly for the oil press system of injection molding machine, which has great significance for reducing the energy waste and improve the production efficiency.

2. Introduction to the equipment system

2.1 INVT injection molding machine is composed of the electro-hydraulic servo system product

INVT kinway electro-hydraulic servo drive system is mainly composed of dedicated servo drive, three-phase AC permanent magnet synchronous motor, servo hydraulic pump pressure sensor and other parts. Adopting advanced DSP and permanent magnet AC servo motor to achieve pressure, automatic flow control and other automatic control functions of electric hydraulic control system.

Dedicated servo driver: it’s derived from a mature, stable and reliable hybrid power automobile motor servo controller, and is the special drive designed for injection molding machine electro-hydraulic servo system development. It contains process ring, speed loop and current loop, and the high performance digital signal processor(DSP)and low cost single-chip have realized the high performance vector control, sensorless torque control, precise position and speed control, high speed control of non-linearity and flux weakening, low speed control of position correction space vector. Through strict electromagnetic compatibility, high and low temperature, humidity, vibration test, it can adapt to a variety of harsh environments and has passed CE certification.

Three-phase AC permanent magnet synchronous motor: Rotor magnet is composed of the high-temperature magnetic Nd-Fe-B material, it adopts surface mount fixed mode with a wider range of speed adjustment and more reliable high-speed operation. Due to the usage of slender structure, the motor rotor inertia is small with faster dynamic response, while the motor running noise is lower.

Servo hydraulic pump: select Sumitomo servo hydraulic internal gear pump.

Speed (flow) feedback device: adopt the mechanical rotary transformer with solid structure, high temperature resistance, anti-vibration, anti-interference ability as a position feedback components, INVT has developed the dedicated signal processing chip used with the rotary transformer, the speed feedback accuracy reaches 4096 pulses per revolution, it’s enough to meet the control accuracy needs of injection molding machine.

Pressure feedback device: adopt imported Swiss Trafag pressure sensor

2.2 The composition diagram of INVT injection molding machine electro-hydraulic servo system

As shown in the figure, the INVT kinway injection molding machine electro-hydraulic servo system is mainly composed of the servo drive controller, motor rotor position / speed sensor, permanent magnet synchronous motor, coaxial connected pump with the servo motor, and the pressure sensor detecting system oil pressure and other key components.

3. Load movement characteristics

Figure 1, the first half of the picture shows the power consumption of the quantitative pump, variable pump, servo three systems in the whole machine operating; the latter half of the picture, the dark blue region displays the energy consumption difference of the quantitative pump system and servo electro-hydraulic system in the same operating condition. The two larger areas are the holding pressure and cooling part of the whole operating, we can see that the actual energy-saving effect depends on the proportion of holding pressure and cooling time in the entire cycle.

Energy-saving rate is not only related to the machine, more importantly depends on the molding process. Reckless commitment of more than 50% energy saving rate is irresponsible. There are cases of energy-saving rate ranging from 20% -70%, in the non-rapid molding process, the general energy efficiency is 40% or more.

4. Control requirements

The analog signal is directly applied to the input end of system pressure reference signal and system flow reference signal of the servo drive; the pressure sensor of the oil pump outlet is connected to the pressure feedback signal port of the servo.

The servo system conducts the pressure and flow signal PI adjustment via the access, change the output torque and speed of servo motor, thus changing the output flow Q and pressure P of pump motor, And through the rotary encoder on the motor and the pressure sensor in the oil circuit, the real situation is fed back to form a high-precision double closed-loop control to meet the required size and flow rate of the injection molding machine in the process, so the energy waste can be avoided.

5. Electrical connection

5.1 Complete the main circuit terminal wiring

1) Connect the input power cables to the drive power input terminals L1, L2, L3, connect the grounding conductor of input power cable to any one of the grounding screws (PE) of drive, and turn the screw to appropriate tightness to ensure smooth connection.

2) Connect the three-phase input terminals W V U of the motor to the connection terminal W V U of drive servo motor and turn the screw to appropriate tightness to ensure smooth connection. Connect the motor ground terminal to any ground screw (PE) of the drive. Connect the motor temperature resistance terminals to the driver terminals T1, T2 and turn the screws to proper tightness to ensure smooth connection. Connect the motor rotary transformer connection terminal to the driver connector CN2 and tighten the fixed screw.

3) Connect the two terminals of braking resistor to the drive terminals U +, PB and turn the screws to appropriate tightness to ensure smooth connection.

5.2 Refer to the wiring diagram of controller cover and complete the connection of control section

5.3 Complete the installation of motor and oil pump on the injection molding machine, make sure that the connection of oil circuit and motor wiring are correct.

6. Protection function

Alarm protection code quick check list

| code | protection content | meaning |

| Err01 | IPM fault | The power module instantaneously passes the short circuit current |

| Err02 | overload | The output current exceeds the permissible operating current of the driver |

| Err03 | DC overvoltage | The main circuit DC voltage is abnormally high |

| Err04 | DC undervoltage | When the motor is energized, the main circuit DC voltage drops to the protection value |

| Err05 | Forward over speed | The forward speed of servo motor is abnormally high |

| Err06 | Module overtemperature | The heat sink of servo drive is overheated |

| Err07 | Motor overtemperature | Servo motor winding overheat |

| Err08 | Software failure | The servo drive software is running abnormally |

| Err09 | CAN fault | Debugging, the user program does not contain this alarm |

| Err10 | Environmental overtemperature | The air temperature in the drive is overheated |

| Err11 | Self-test failure | Drive internal hardware exception |

| Err12 | Task reentry | Software program call error |

| Err13 | Oil pressure overpressure | The pressure of hydraulic system exceeds the allowable value |

| Err14 | Reverse over speed | In process control mode, the motor reverses overspeed |

| Err15 | Pressure sensor failure | The pressure sensor wiring is wrong or itself is damaged |

| Err16 | Braking resistor is damaged | Braking resistor is not connected or damaged |

| Err17 | AC overvoltage | The input AC voltage is too high |

| Err18 | EEPROM fault | Servo Unit EEPROM Data Abnormal |

| Err19 | Enable undervoltage | When the motor is energized, the main circuit DC voltage is too low |

| Err20 | AC undervoltage | The input AC voltage is too low |

| Err21 | Brake overload | Brake resistor overload heat, causing the temperature is too high |

| Err22 | Node failure | CAN communication error between master and slave system |

| Err23 | Rectifier unit failure | AC voltage and DC voltage detection value does not match |

| Err24 | Power on timeout | Power-up relay pull-up time-out |

| Err25 | 485 communication failure | When the process instruction mode is 485 consecutive, the 485 communication abnormal driver reports the fault |

7. Debugging points

HMI connection: The MH500 series electro-hydraulic servo system supports hot-swapping when the HMI is powered on. The HMI can be connected to the drive by inserting the DSUB9 terminal of HMI into the CN4 terminal in the front cover of drive during commissioning. As shown below.

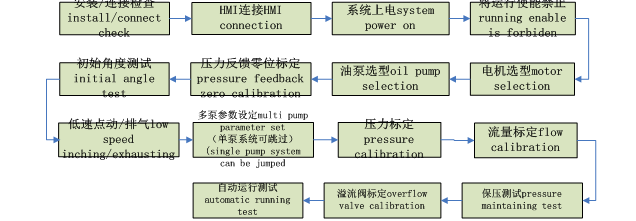

Debug flow chart:

The system can run after setting according to the order.

8. Precautions

To ensure good performance and long service life, install the MH500 servo drive in the following recommended environment to ensure that the drive is protected from damage.

| Note SHAPE \* MERGEFORMAT | 1.Avoid direct sunlight, no direct outdoor usage. |

| 2.No usage in corrosive gases and liquids. | |

| 3.No usage in the oil mist, splashing water environment. | |

| 4.No usage in salt spray environment. | |

| 5.No usage in rain, humid environment. | |

| 6.The filter device must be added when the metal powder or silk spinning fiber fly floats in the air. | |

| 7.No usage in mechanical shock, vibration occasions. | |

| 8.when the ambient temperature is higher than 55 ℃, the cooling measures must be taken before usage. | |

| 9.overheating and overheating can cause equipment failure. It is recommended to use in the range of -20 ℃ ~ + 55 ℃. | |

| 10.away from the power supply noise, such as welding machine, high-power electrical equipment will affect the usage of the device. | |

| 11.radioactive materials will affect the usage of equipment. | |

| 12.flammable items, thinner, solvent should be away from the equipment. |

9. Introduction to product features

Advantages of Hydraulic Servo System of INVT Injection Molding Machine

9.1 Product performance advantages

1) INVT servo drive is the special servo drive for the injection molding machine, the overload factor reaches 2.5 to 3 times; compared to the 1.5 times overload factor of so-called servo (vector inverter) on the market transformed by the inverter, the INVT products have the unique advantages of professional servo;

2) energy consumption saving: compared with the traditional quantitative pump, servo system has 50% -70% energy saving, someone even up to 80%; compared with the variable pump, the servo motor energy saving has a minimum commitment of 25%;

3) Increase the number of qualified products per unit time to more than 5%;

4) Flow response time 50MS, pressure response time 100MS

5) Product weight repeat error <0.3%

6) Screw shot stop position error <0.1mm

7) save the waste energy of high pressure throttle of the traditional technology;

8) saves the consumption of hydraulic cooling system

9.2 Control product quality according to the control process of automobile products

1) comprehensive test of high and low temperature conditions

2) Strict vibration test

3) ISO90001 / TS16949 supply chain management process, and production process control

4) Conduct strict factory aging test for motor and servo drives to eliminate early failure of electronic components

5) INVT servo products pass the European electromagnetic compatibility standard CE certification

6) two years quality assurance period of drive, so that customers don’t need to worry about the recovery of investment costs (energy saving / high efficient)

9.3 Advanced motor control algorithms and injection molding control strategies

1) Modern motor sinusoidal vector control algorithm to achieve the perfect torque control of the motor:

2) The motor is running more smoothly; faster response; lower noise;

1) The whole system is more efficient (system efficiency greater than 90%);

4) Self-adaption / non-linear control to meet the flow pressure requirements of different injection molding models, reduce the overshoot of flow and pressure, eliminating the shot "beating";

5) decoupling PQ control, increase the response speed of injection molding machine, the mutual conversion of smooth flow and pressure control (requires the coordination of host computer);

6) According to the needs of injection molding process, to achieve uniform / variable speed jet control, and smoothly transit from the flow control to the pressure maintaining control.

9.4 Flow control with pressure compensation

1) Flow, pressure double closed-loop control has ensured the pressure and flow requirements of injection process;

2) It can compensate the flow error produced by the pump leakage in high pressure, flow control is more accurate;

3) it’s equipped with different pumps to achieve different pressure compensation and accurate flow control.

9.5 mature old machine transformation program (single pump / multi pump)

1) since 2008 , it has entered into the old machine transformation industry, it has a very mature program for Haitian and other brands injection molding machine transformation;

2) The connection between the motor and oil pump adopts the high precision coupling type, one is easy to maintain, and the servo motor and oil pump are frequently started and stopped in operation. The embedded connection of the two will increase the jammed risk of connecting shaft. The coupling can avoid the risk;

3) Full monitoring of motor and drive temperature changes, real-time adjustment of control parameters.

4) For large-scale confluence machine, it combines with the oil circuit to achieve the pressure relief control of minimum reserve amount l and extend the lifetime of pumps and motors.

5) Conduct the transformation construction of 300T ~ 3300T medium and large-scale injection molding machine for a number of well-known manufacturers (end users), which has received unanimous praise.

Conclusion

According to the market analysis of plastic products, China's plastic machinery industry output value is about 20 billion yuan each year, while the domestic market demand reaches nearly 22 billion yuan, the demand for injection molding machine gradually extends from the south to the north, east to the west, which has also driven the rapid development of plastic industry and other related industry. But at the same time the industry competition is becoming increasingly fierce, with the thorough of national energy-saving emission reduction policies, in addition to attention to product quality and brand, the manufacturers are considering how to save energy in response to national calls and reduce production costs.

From the injection molding machine process, we can know that the cost of energy consumption accounts for a large proportion in the injection molding products cost, and effectively reducing the power loss is concerned by the injection molding machine manufacturers and users. Achieving the significant effect of energy-saving transformation has become the primary task of the injection molding industry upgrading. The application of INVT electro-hydraulic servo system in the injection molding machine industry has fundamentally met these needs, the leading technology and the increasingly mature application in the injection molding machine market have gained a lot of praise of manufacturers and users, the future usage of electro-hydraulic servo will become the mainstream of injection molding machine market.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.