Abstract: Energy shortage and environmental pollution has become the primary topic in today social development to be solved. Remote parts of the animal husbandry and water problems tend to have also been regional restrictions. In view of the above problems photovoltaic water pump arises at the historic moment. This paper the basic principle and composition of photovoltaic pump system were summarized and research a new system to explain that how it can help a kind of people who don’t know how to debug the inverter’s parameters, so in this case, it’s easy to control solar pumping system though HMI, like use a mobile phone, it’s easy to use and maintenance for end customers.

Key words: Solar pumping, GD100-PV inverter, HMI, INVT, Photonsolar.

Overview

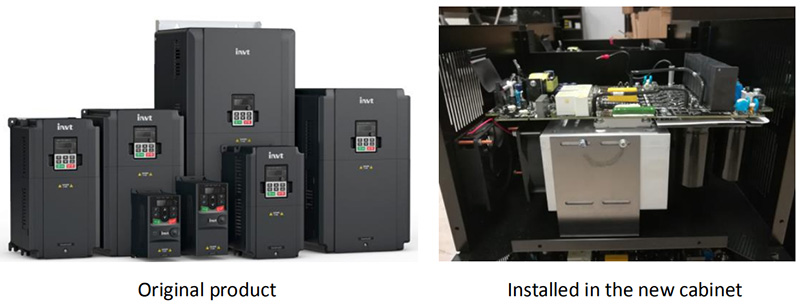

GD100-PV is a special inverter based on INVT GD20 platform with many good features. It can support DC input directly, no need battery, with excellent MPPT controller, support water level logic control, can sleep and wake up automatically, adjust speed according to the temperature and sunshine. GD100-PV also can support IP54 cabinet 1Φ220/3Φ220&380, INVT can provide abundant optional parts, such as PV/AC auto-switch module, boost module for ≤ 2.2kW, optional GPRS part for monitor (Apps & Website). Multiple protections(Reverse connection/Overvoltage/Overheat…)

Commissioning Procedure

The basic commissioning procedure is as follows:

• Set the correct motor data and enter into parameters.

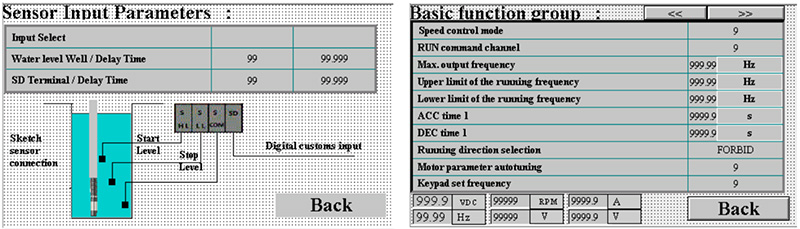

• Determine the operating parameters (Lower running frequency, AC / PV, solar enable/disable) and enter into parameters.

• Test Operation:

Close the DC breaker. The inverter automatically runs with a delay of 10 seconds. Check the water yield of the pump.

If the water yield is normal, the trial run is successful. If the water yield is under the normal value, exchange any two motor cables, connect the cables, and perform trial run again.

Advanced settings

Note: The default settings of the inverter for the water pump can apply to most conditions and the advanced settings are not required in most cases.

• PI adjustment to the water yield

If the user requires large or low water yield, it is necessary to adjust PI (P15.06~P15.10), GD100-PV series solar pumping inverters commissioning guidelines properly. The bigger PI parameters, the stronger the effect is, but the frequency fluctuation of the motor is bigger. In reserve, the lower the water yield is, the more stable the motor frequency is.

• Special settings for single phase motors

a) When the single phase motor is in bad running performance, the user can adjust P04 VF curve settings: set P04.00=1 and set P04.03~P04.08 to appropriate values according to commissioning conditions; increase the voltage if the motor cannot start and decrease the voltage if the current is high.

b) When the light is normal and the system starts slowly, increase P15.28 initial voltage differential value appropriately.

c) For single phase motors with two-phase control (capacitor-removing):

① The maximum voltage needs to be less than 1/1.6 of the bus voltage. It is recommended to set the rated voltage P02.04 less than 200V, or limit the maximum voltage output by multi-dot V/F curve.

② Observe the currents of the windings through P17.38 and P17.39, the switched current is the combination current of the two windings. The impedances of the windings are different, so the currents are different at the same voltage output.

③ P04.35 can be used to change the output currents of the main and secondary windings. It is recommended that qualified engineers perform adjustment since the voltage adjustment is associated with motor design parameters. Otherwise, the motor performance may be impacted.

Project introduction

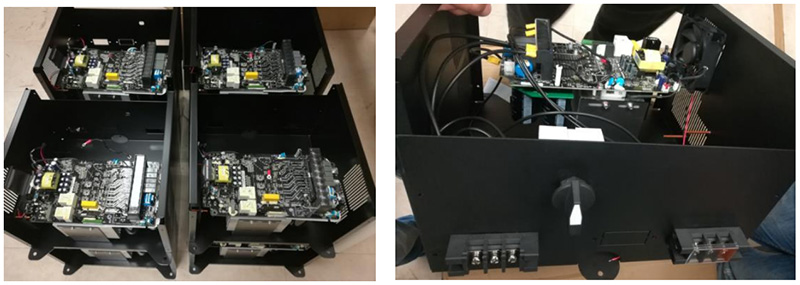

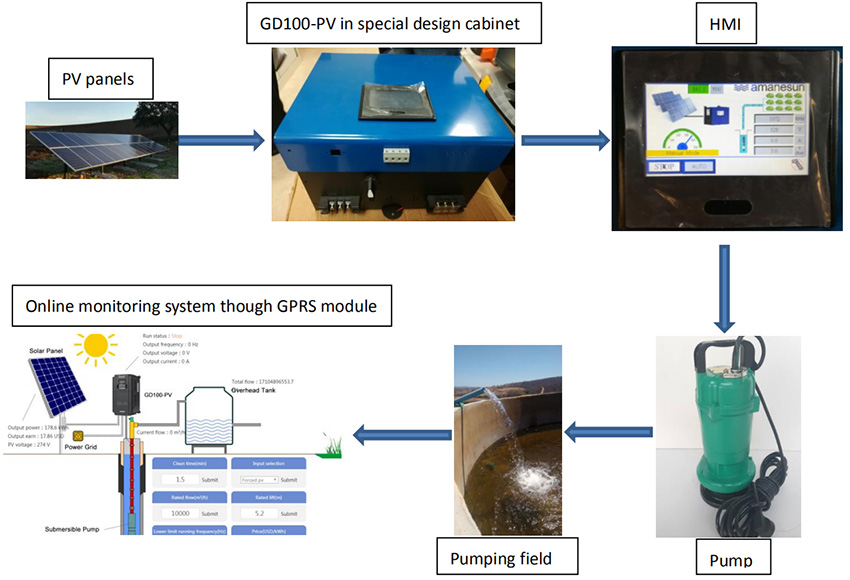

Photonsolar, the company is the agent of INVT mainly for solar pumping inverter in Belgium. Its main business is in Morocco. And the most application is solar pumping inverter. In local place, the end customers usually use the solar pumping system outside, normally the field is far away from the city or the house. So the customer require it should have good protection with low cost. And most of them are farmers, they don’t know how to set parameters, how to debug the parameters. So in this situation, we try to make some change for that market. We try to research a new cabinet, and do thermal simulation, and connect HMI to control the GD100-PV solar pumping inverters.

System configuration

System start/stop and set parameters though HMI, and power input from solar panels, there are 20 pcs solar panels. Solar panel’s information is as below:

260W, Voc=37.7V, Vmppt=30.4(Winter)/26.7(Summer).

Inverter’s information is as below: GD100-004G-4-PV

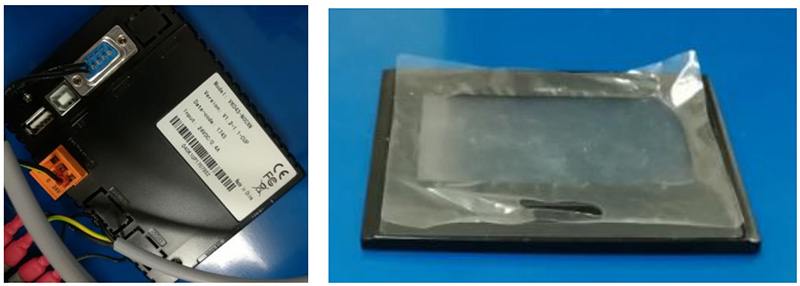

HMI’s information is as below:

VK043-N0CXN

GD100-PV with cabinet, it’s using Photonsolar’s local design cabinet.

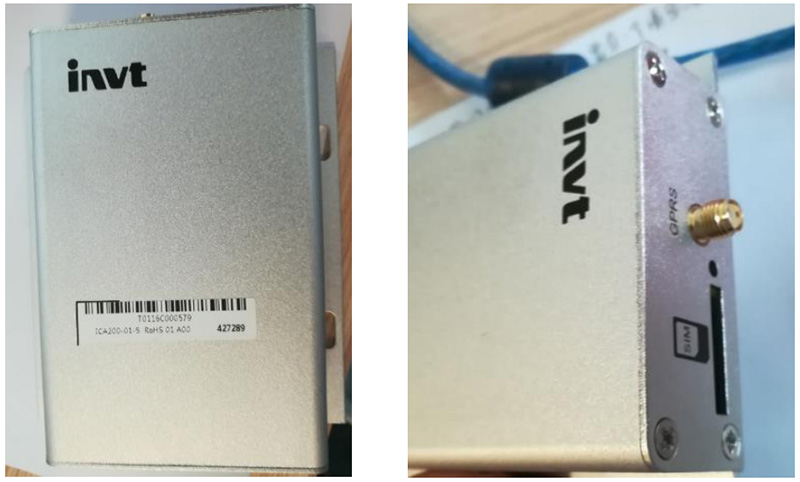

GPRS information is as below:

And pumping motor is using local place brand. System wiring is as follows.

System diagram

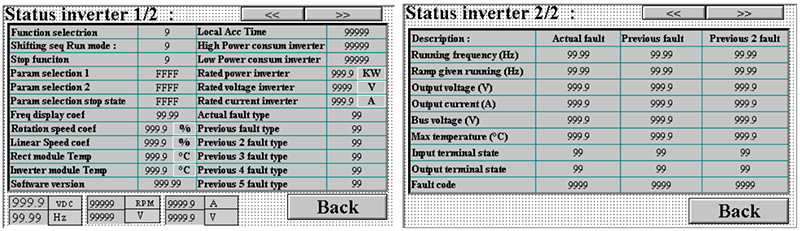

Inverter’s setting parameters, for example:

P00.01=2 Communication mode

P00.11=25, P00.12=25

P02 group parameters

P15.00=1, Photovoltaic function enable

P15.01=1, MPPT function

P15.05=60%, PID output lower limit frequency.

P15.06, KP1

P15.07, KI1

P15.08, KP2

P15.09, KI2

Example 1: P15.06=10, P15.07=10, P15.08=35, P15.09=35.

Example 2: P15.06=10, P15.07=10, P15.08=20, P15.09=20.

According to the requirements of application, to adjust parameters (P15.06~P15.09).

…

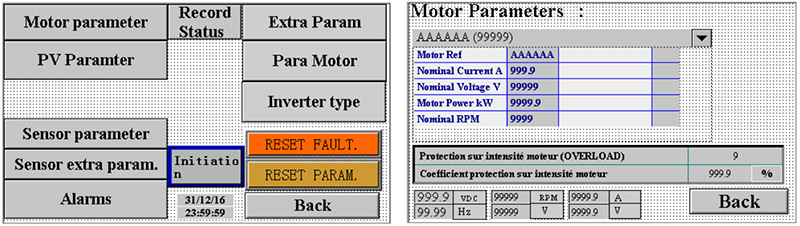

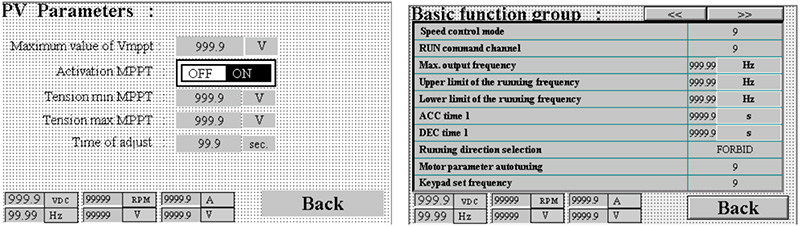

HMI Program

User interface for alarming and scheduling:

Features and advantages

• End customers can use solar pumping system easily, and there is not too much requirements for the technical knowledge.

• GD100-PV’ MPPT tracking function is excellent to use the solar energy, end customers has no necessary to pay for the electric cost to the government.

• In some remote area, there is no AC power, but the farmers need irrigation by pumping, so in this case, INVT’s solar pumping inverter can solve the problem. Only need to use free solar.

• HMI screen is easy to see and touch, suitable for any customers, and there are many information to show on the screen, it will reduce the service cost for technical engineers.

• With INVT’s GPRS module, the end customer can also control the GD100-PV through internet or mobile phone’s APPs. Easy to use and monitor the pumping.

• With the special design of the cabinet, GD100-PV has good protection, it’s much better than IP20 before.

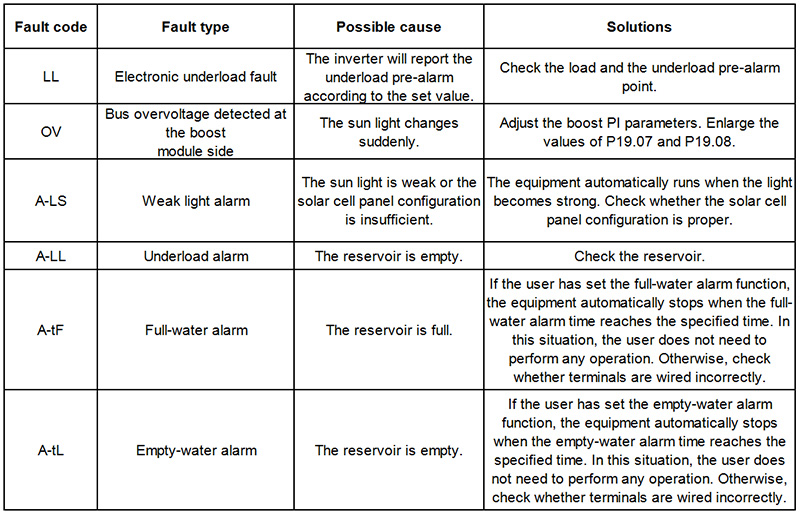

Troubleshooting

See the following table for detailed solution and check the corresponding abnormal state(Common Faults). Eliminate the fault and ask for relative help. Check to eliminate the fault and carry out fault reset to run the inverter.

Summary

The GD100-PV solar pumping system’s performance on this project is outstanding in the regard of economical high efficiency and very reliable. It has proven to the customer that MPPT function based on inverter, it’s very suitable for irrigation or pumping purposes, and therefore the end customers like it very much.

References

[1]GD100-PV Series Solar Pumping Inverter Operation Manual. Shenzhen INVT Electric CO., LTD.

[2]INVT HMI Programming Manual. Shenzhen INVT Electric CO., LTD.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.