Abstract: This paper mainly presents INVT GD20 series inverter used for conveyor (Treadmill), application in Gym and hospital in India. It introduced the process and application of treadmill application, and gives the detailed drive configuration.

Keywords:Treadmill, GD20

1. Introduction

The treadmill is a device generally for walking or running while staying in the same place. It is common equipment in the fitness centers & medical testing in hospitals with the belt system controlled by the motor, people can run or walk passively at different speeds. Besides, users can experience different running environment, such as flat land, uphill or variable speed to reach different training purposes, with the auxiliary electronic equipment on the treadmill. Most DC brush motors are used for the past treadmill. However, its weaknesses are the high failure ratio of carbon-brush and commutator device, high maintenance cost and inefficient low-speed torque. Thus, most manufactures adopt the AC motor with the variable frequency drive to improve the weaknesses of the DC motor.

GD20 series mini type general vector inverter, positioned as using the high performance mini product of small power market. GD20 adopted the leading international vector control algorithm, can used in applications like treadmill, Plastic machinery, Printing and packaging, Environmental protection equipment, Ceramic equipment, Woodworking equipment. The main control features are as follows:

• Single Phase 220V: 0.4kW to 2.2kW

• Three Phase 380V: 0.75kW to 2.2kW

• Supports wall mounting and rail mounting

• Sensorless Vector control

• Built-in Braking unit

• HDI/Y1 terminals

• Mini structure: Smaller size, saving installation space.

• Interface: Standard RS485, rich input/output terminals, external keypad.

• Up to 25 fault protections: Protect from over Torque, over current, over voltage, under voltage, over temperature, phase failure, etc.

2. Brief introduction of treadmill process:

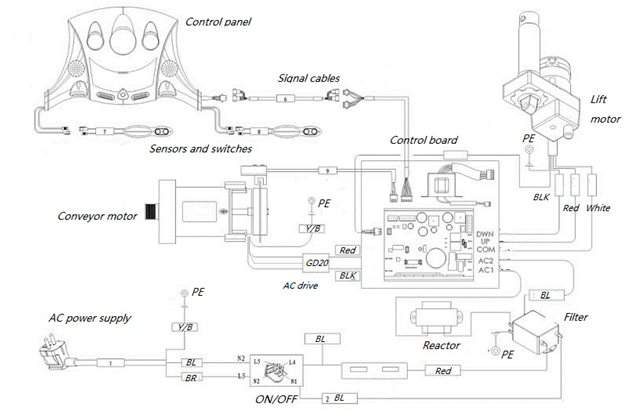

The system diagram of treadmill is as below and the features are as follows:

1. There are two motors in one treadmill: one is for lift, the other is for conveyor. Only conveyor motor is controlled by GD20 AC drive.

2. The GD20 low voltage vfd is to produce instantaneous response to each footfall, smooth running operation throughout the entire speed range and high starting torque interfacing with the microcontroller start and stop command given to S1 and 24V and PW and com are shorted and frequency is decided through A12 and com.

3. The frequency of GD20 is set according to KM/Hr and rpm calculation which is decided by reference voltage to analog input.

3. Site information and drive configuration

1) Case1: Health and Fitness Mumbai

Health and Fitness was founded in 2000, are renowned manufacturer supplier and exporters of fitness equipment covers around 1500sqft and has around 40 machines per month.

The below table listed part of the applications and INVT drive configurations.

| SN | Application | Voltage | Power rating | INVT drive Model No. |

| 1 | Treadmill(hospitals) | 230V | 1.5kW | GD20-1R5G-S2 |

| 2 | GYM | 230V | 2.2KW | GD20-2R2G-S2 |

The parameters list is as follows:

| Function Code | Name | Description | Setting |

| P00.00 | Control model | 0:V/F control 1:Sensorless vector control 2:Torque control ( sensorless vector control) | 1 |

| P00.01 | Run command source | 0:Keypad (LED extinguished) 1:Terminal (LED flickering) 2:Communication (LED lights on) | 1 |

| P00.03 | Maximum frequency | 10.00~400.00Hz | 110.00Hz |

| P00.04 | Upper frequency limit | P0.05~P0.03 | 110.00Hz |

| P00.06 | Frequency A command source | 0: Keypad 1: AI1 2. AI2 3: HDI 4. Simple PLC 5: Multi-step speed | 2 |

| P00.11 | Acceleration time 0 | 0.1~3600.0s | 5.0s |

| P00.12 | Deceleration time 0 | 0.1~3600.0s | 5.0s |

| P00.14 | Carrier frequency setting | Setting range:1.0~15.0kHz | 15kHz |

| P02.01 | Motor rated power | 0.4~900.0kW | 3.7 |

| P02.02 | Motor rated frequency | 0.01Hz~P0.03 | 50.00Hz |

| P02.03 | Motor rated speed | 0~36000rpm | 960 |

| P02.04 | 0~36000rpm | 0~800V | 415 |

| P02.05 | Motor rated current | 0.8~6000.0A | 8.8 |

| P03.00 | ASR proportional gain Kp1 | 0~100 | 10 |

| P03.03 | ASR proportional gain Kp2 | 0~100 | 10 |

| P5.01 | S1 Terminal function | 1:Forward | 1 |

| P5.02 | S2 Terminal function | 2: Reverse | 2 |

| P05.39 | Upper limit of AI2 | The setting range of P05.39:P05.37~10.00V | 5 |

| P08.40 | PWM selection | 0: PWM mode 1, three-phase modulation and two-modulation 1: PWM mode 2, three-phase modulation | 000 |

After setting the parameters as per the above the list, GD20 is successfully run from last 3months.

4. Conclusion

Field running experience shows that INVT GD20 series inverter has good control performance and stability on treadmill application. So far both the OEM are satisfied with the performance of GD20.

References

[1] Operation Manual of GD20 series , Shenzhen INVT Electric Co., Ltd.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.