Abstract: This article mainly presents INVT AX series PLC and EtherCAT servo system, in this EtherCAT communication system, we provide solution from single axis to five axis system with etherCAT motion networks developed for better production. Here PID control function also implemented for heater control mechanism. This machine major task achieved through AX71 PLC is PID block execution with self-tuning function and control the temperature within 1 degree range.

Keywords: AX series PLC, HMI, DA200 servo, motor, EtherCAT, Modbus Communication.

I. Introduction

The major processes of this machines are feeding, indexing, heating, moulding, stretching, unloading with product and PID control mechanism.

1) Feeder: In feeder section raw material(tube) feeding uniformly through conveyor and mechanical assembly to loader section, at loader section pneumatic system used for proper pick and place at location.

2) Indexing: Here single servo used for product feeding uniformly and in sequence, As per the cavity system indexing servo mechanism working.

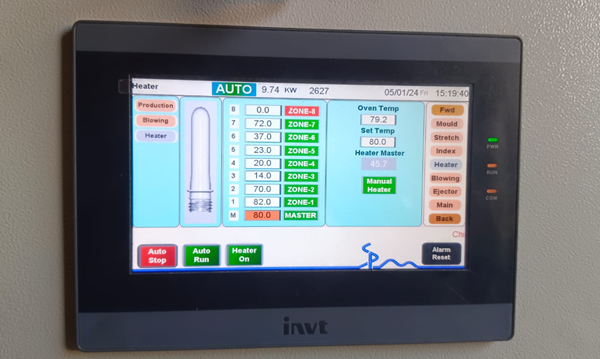

3) Heating section: In this section proper heat provide to raw material and temperature control AX PLC new PIDs blocks, as per the sensor feedback PID block working and output provide to controller for heating elements through HMI RS232 serial port Modbus communication. This temperature monitoring in PLC through AX-04PT module.

4) Moulding: In this section as per require design dye(mechanical), In some machine dye operated through hydraulic system and some machines through servo drive installed then executed through logic. In hydraulic system control through pressure and in servo system position to control.

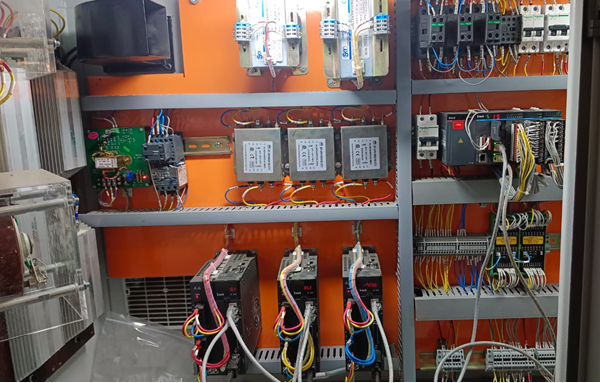

Figure – AX PLC Panel and process line

5) Stretching: Stretching plays an important role for bottle manufacturing. In stretching servo movement length of product design and proper stretch for final product. After moulding and stretching section material sent to unloading section with pneumatic system to unload products.

6) HMI used for operator interface and parameter setting of machines, In new system heater controller communicated with HMI RS232 Modbus port for data write functions. All tags of the PLC imported in HMI without defining individual tags.

2. Project information and Solution

2.1 Project information

Site information: Customer work in plastic moulding machine in Ahmedabad.

Bottle making machine: In this application all axis control in EtherCAT system with INV AX PLC and etherCAT servo system.

Figure - HMI Image

2.2 INVT solution

Application | Motor/PLC/HMI | Inverter/Servo | Quantity |

Stretching | SV-ML13-3R0E-4-9A0-1000 | SV-DA200-3R0-4-NO | 1 |

Moulding | SV-ML13-1R5E-4-9A0-1000 | SV-DA200-1R5-4-NO | 1 |

Indexing | SV-ML13-1R5E-4-9A0-1000 | SV-DA200-1R5-5-NO | 1 |

AX-PLC | AX71-C-1608N | - | 1 |

Module | AX-PWR–Power module | - | 1 |

Temperature | AX-EM-04PTC | - | 1 |

DO | AX-EM-0016DN | - | 1 |

Temperature | AX-EM-04PTC | - | 1 |

HMI | VS-070QS | 7inch HMI | 1 |

Controller | Heater controller | 8 zone | 1 |

3. System commissioning

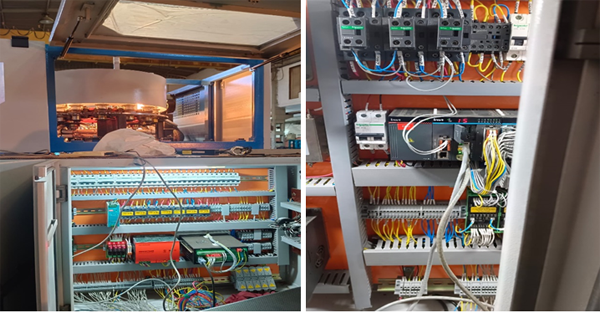

Figure – Control Panel and Machine mechanism

Figure – Process line and servo installation

Figure – AX71-C-1608N INVT make PLC and modules

4. Advantages and benefits

• Here 3-axis system executed, in same application multiple axis system executed easily without major changes in the programs.

• All servo work in EtherCAT communication

• Accuracy too much high and speed also maintain as standard

• Here complete system working absolute mode & data function blocks working as standard requirements of the applications

5. Conclusion

As per study and application execution, these industries multiple axis type of machines for bottle making machine. These machines installed in production line for 24x7 running system require. We tested at site for 1-3-5 axis system and give speed more than 6000BPH, cycle time 2 to 2.5 second when system running continue for production.

In this application we can executes our system with 1 axis, 3- axis and 5 axis, later more axis we can easily executes with proper sequence and solution. With reference of these projects, we can easily set up market for many plastic industries.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.