1. Background

Closed rubber mixer is mainly used for plasticizing and mixing of rubber. it is a machine equipped with a pair of relatively rotating and specific shape rotors, which can intermittently mold and knead polymer materials in a closed state with adjustable temperature and pressure. It is mainly composed of an mixing chamber, a rotor,rotor sealing device, feeding and pressing device, unloading device, transmission device and machine base.

At present, most closed rubber mixers on the market are driven by asynchronous motors. With the development of motor technology, in order to improve the efficiency and performance of equipment, OEMs have begun to apply permanent magnet synchronous motors and permanent magnet direct drive motors; in particular, permanent magnet direct drive motors reduces traditional losses and has the advantages of compact structure, large starting torque, high efficiency, smooth operation, high reliability, low noise, and easy installation.

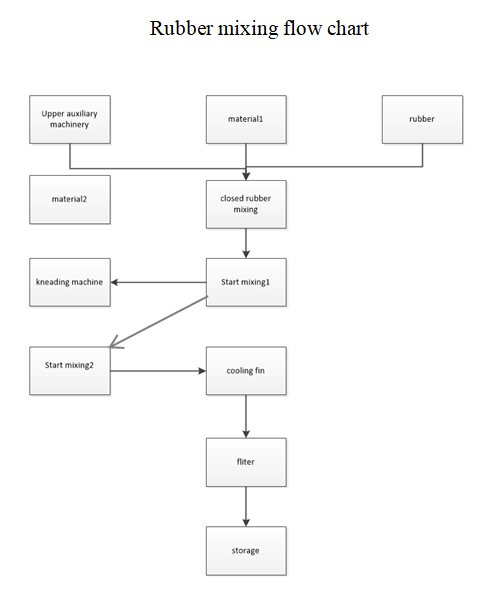

2. Process introduction

3. Customer needs

In the fierce competition in the rubber and plastics industry, the requirements for the production efficiency, energy-saving effect, equipment size, noise and service life of closed rubber mixers internal mixers are getting higher and higher. Currently, most of the asynchronous motor solutions on the market are in efficiency, size, There is relatively large room for improvement in terms of noise, so permanent magnet synchronous motors are gradually introduced. With the development of technology, permanent magnet direct drive motors have further promoted the improvement of efficiency, and the requirements for inverter control are also higher. This time the requirement is 2.5 times overload capability, using closed-loop control.

4. INVT solution

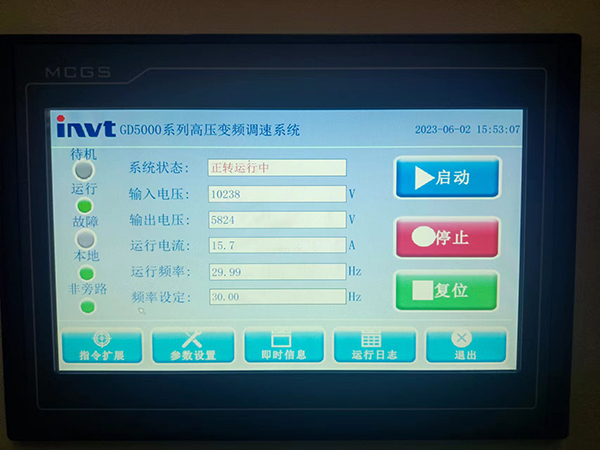

In response to customer needs, INVT GD5000 high-voltage VFD uses dedicated drive software in closed rubber mixers with closed-loop control to drive the permanent magnet direct-drive motor. This solution has the advantages of high efficiency, energy saving, small footprint, and the motor is water-cooled for heat dissipation and has low noise.

Value:

* Core aspects: The permanent magnet direct drive solution for closed rubber mixers is a new technological breakthrough that will lead the market for 2-3 years.

* Other aspects: Compared with the early asynchronous motor accelerator and reducer solution, the permanent magnet direct drive is half the size. The motor is water-cooled and makes almost no noise. The permanent magnet direct drive eliminates the need for a reduction mechanism and greatly improves efficiency.

* 2.5 times overload capacity

5. On-site application pictures

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.