Project Background

CNC six-side drilling is mainly used in the panel furniture industry, in order to make the standard and non-standard customization can be accurate in accordance with the needs and processing of panels, in the use of CNC six-side drilling, it is necessary to pre-processing steps, the order of movement, the route of the tool and the selection of the relevant cutting dosage, in accordance with the prescribed digital form of the program into a program to record the control media, to achieve the link between the person and the CNC six-sided drilling to realize high-efficiency production.

Equipment Principle

CNC six-side drilling works by precise programming, supported by CAM software, executed by mechanical components and coordinated by an efficient control system. During machining, digital information on the control media is fed into the control system, which operates and controls the input information.

INVT Solution

In order to help the production of the customer, to realize the high precision and high efficiency processing of plates.

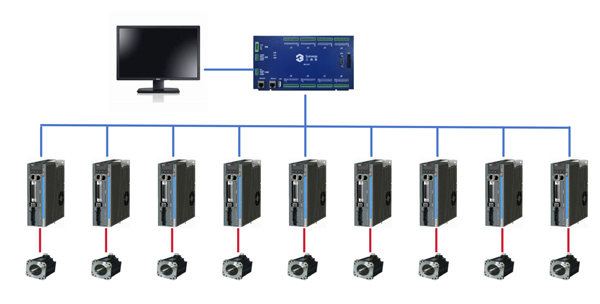

Based on the DA180A servo with stable performance, high cost performance, fast response and high positioning accuracy, INVT provides a system solution of DA180A EtherCAT bus type servo for the customer. The servo is applied to X, U, Y, Y1, Z, Z1, V, W and A axes respectively.

Customer Benefits

By means of INVT solution.

1. Equipment accuracy improvement: adopting INVT DA180A EtherCAT type servo, it adopts bus communication with the upper computer system, the synchronization cycle is 1ms, the communication speed is fast, and the anti-interference ability is strong.

2. Response speed improvement: servo motor using 17-bit absolute encoder, fast response, high positioning accuracy, can maintain the current position after power failure.

3. Safety enhancement: DA180A built-in dynamic braking function, in a sudden power failure or other external factors such as servo motors in high-speed operation can be stopped immediately, to protect the equipment from impact damage.

4. Operation and maintenance efficiency: servo installation and commissioning operation is simple, easy to get started, greatly reducing the operation and maintenance of labor costs.

On-site application pictures

The DA180A EtherCAT bus-based servo solution improves the cost-effectiveness of the equipment, enhances the market competitiveness of the equipment manufacturers, and also reflects the strong comprehensive servo performance of INVT. At present, it has already been applied in batch by customers.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.