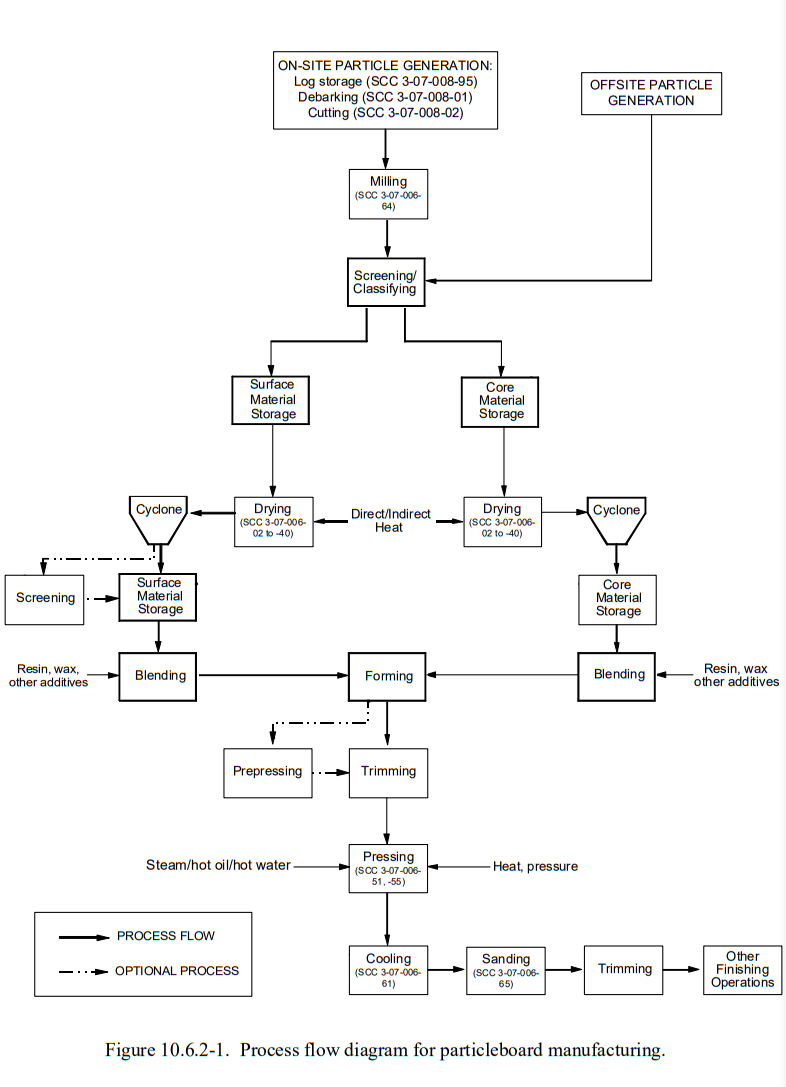

Abstract: The general steps used to produce particleboard include raw material procurement or generation, classifying by size, drying, blending with resin and sometimes wax, forming the resinated material into a mat, hot pressing, and finishing which include sanding trimming.

Keywords: Gd200a drive of multiple ratings, Da200

1. Introduction

PLANT PROCEDURE:

Particleboard or chipboard is manufactured by mixing particles or flakes of wood or jute-stick together with a resin and forming the mixture into a sheet. The raw material is fed into a disc chipper with between four and sixteen radially arranged blades. The chips from disk chippers are more uniform in shape and size than from other types of wood chippers. The particles are then dried, and any oversize or undersized particles are screened out.

Panel production involves other chemicals including wax, dyes, wetting agents and release agents, to aid processing or make the final product resistant to water, fire or insects.

After the particles pass through a mist of resin sufficient to coat all surfaces, they are layered into a continuous carpet. This 'carpet' is then separated into discrete, rectangular 'blankets' which will be compacted in a cold press. A scale weighs the flakes, and they are distributed by rotating rakes. In graded-density particleboard, the flakes are spread by an air jet that throws finer particles further than coarse ones. Two such jets, reversed, allow the particles to build up from fine to coarse and back to fine.

The formed sheets are cold-compressed to reduce thickness and make them easier to transport. Later, they are compressed again, under pressures between 2 and 3 megapascals (290 and 440 psi) and temperatures between 140 and 220 °C (284 and 428 °F) to set and harden the glue. The entire process is controlled to ensure the correct size, density and consistency of the board.

The boards are then cooled, trimmed and sanded. They can then be sold as raw board or surface improved through the addition of a wood veneer or laminate surface.

2. Project information and Solution

2.1 Project information

Site information: Particleboard company

2.2 INVT solution

Product | Model no. | Qty | Application |

GD200A MULTIPLE RATING | 30 | PARTICLEBOARD MAKING PLANT |

2.3 System commissioning

Control panels

3. Advantages and benefits

* Efficiency by drive is more.

* Easy to operate motor from drive.

* Motor safety more.

* Speed variation with power saving.

4. Conclusion

All drive running as per requirement in particleboard making plant in multiple rating of drive.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.