Recently, INVT has helped the lifting industry to achieve fruitful results in overseas markets. The GD350-19 series inverters have been successfully applied in large tower cranes and shipped overseas in large quantities, including Mongolia, constantly breaking overseas records.

INVT helps tower cranes conquer overseas working conditions

An equipment manufacturer sent batches of large-tonnage tower cranes to Mongolia. The representative model delivered this time is suitable for hoisting construction of large-volume and large-component public buildings and commercial buildings. It has a large working range and can meet the needs of different working conditions; It has large lifting power, fast lifting response and high efficiency.

Customers said that by cooperating with INVT, taking customer needs as the starting point and ensuring high-quality product solutions and services, we can achieve breakthroughs from the first unit in overseas markets to batch delivery in key regional markets, which not only helps national enterprises to embark on an innovative development path , and also work together with global customers to achieve win-win results.

GD350-19 series another new departure

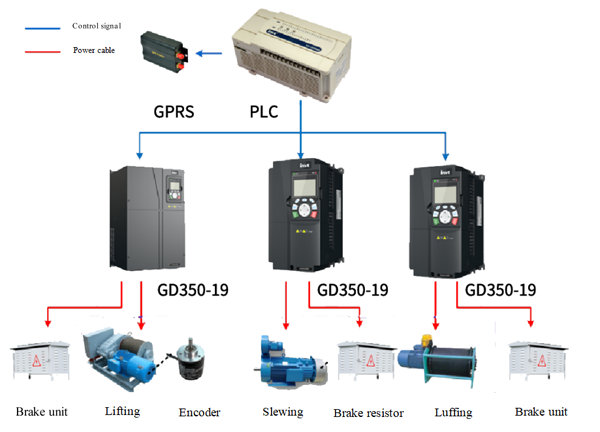

The length of the machine boom is 80 meters, the minimum lifting weight is 15 tons, and the maximum lifting weight is 64 tons. The GD350-19 series VFD is the third generation of special inverter for lifting, which is launched in combination with advanced control theory. It has excellent torque control performance, integrated brake control, zero servo, fast stop, light load speed increase, loose rope detection and other special functions, built-in slewing special curve, and rich expansion modules to meet the application requirements of various tower crane systems, ensuring the safety, reliability and efficiency of tower crane lifting.

This solution has been tested in field applications. The motor power of the lifting mechanism is 170kW, the rated frequency is 25Hz, the maximum operating frequency of weak magnetic field is 75HZ, the lifting mechanism runs smoothly, and there is no hook slipping under heavy load; the slewing operation is stable, the gear switching is smooth; the stop is stable without rebound, and the luffing mechanism runs smoothly

With the technological development demands for large-scale, specialization and intelligence of lifting machinery products and the improvement of the intelligence level of the whole production and manufacturing process, INVT has continuously introduced new products and solutions to plan for the future of the industry. It has formed professional solution products ranging from special frequency converters for lifting to deeply customized intelligent integrated machine control systems and integrated drive cabinets for tower cranes.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.