Abstract: Gantry cranes are types of crane which lift objects by a hoist which is fitted in a trolley and can move horizontally on a rail or pair of rails fitted under a beam. An overhead travelling crane, also known as an Electrical overhead crane or as a suspended crane. The aim of INVT solution is also provide a significant reduction in power consumption, minimize total cost of gantry crane.

Keywords: GD20-09, GD20, Hoist, EOT, Crane

1. Introduction

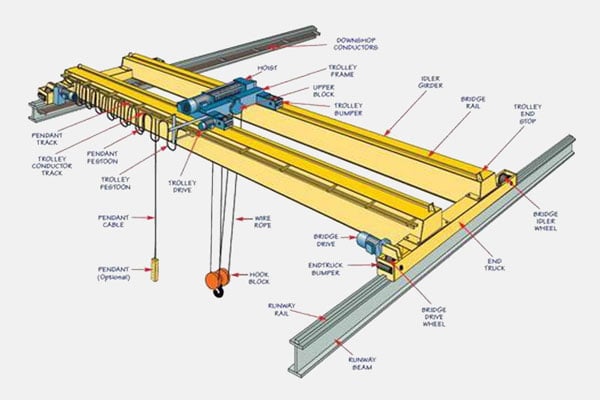

It has the ends of the supporting beam resting on wheels running on rails at high level, usually on the parallel side walls of a factory or similar large industrial building, so that the whole crane can move the length of the building while the hoist can be moved to and fro across the width of the building. A gantry crane or portal crane has a similar mechanism supported by uprights, usually with wheels at the foot of the uprights allowing the whole crane to traverse. Some portal cranes may have only a fixed gantry, particularly when they are lifting loads such as railway cargoes that are already easily moved beneath them. Overhead travelling cranes and gantry cranes are particularly suited to lifting very heavy objects and huge gantry cranes have been used for shipbuilding where the crane straddles the ship allowing massive objects like ships' engines to be lifted and moved over the ship. Gantry cranes have two upright supports which move along two ground based rails. The height of the portals depends on the maximum hook height. Gantry cranes are used in factories and in outdoor storage yards such as railway and shipping storage areas.

MACHINE PROCEDURE:-

2. Project information and Solution

Project information

Site information: Steel/Metal Industry

INVT solution

Product | Model no. | Qty | Application |

VFD | GD20-09-7R5G-4-B | 1 | Hoist |

VFD | GD20-2R2G-4 | 1 | Long Travel |

VFD | GD20-2R2G-4 | 1 | Cross Travel |

3. System commissioning

Control panels

4. Advantages and benefits

1) It is suited for light industrial applications. For Cross travel and long travel we offered GD20-2R2G-4, Economical and high performance drive.

2) For Hoist motor we offered GD20-09, which is economical and dedicated drive with special micro, Inbuilt DBU to reduce external DBU cost, Some drive has Dc reactor to improve power factor, integrates hoisting-oriented

brake logic and conical motor control logic, It can lift up to 20 tons of loads.

3) As INVT drives are high performance drive so It reduces the total crane cost on crane components, runway structure

4) Its ergonomic design offers manual long travel (LT) because of its electric

hoist or motorized chain pulley block.

5. Conclusion

GD20-09 VFD solution is successfully used for Electrical Overhead Travelling crane. which is mostly used in handling of heavy material in every industry. Its provide safety ,Easy and Effective handling, Smooth operation due to VFD, Protect motor from high inrush current. In INVT it is a very good sector, who wants high performance drive with economical solutions against Yaskawa.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.