Abstract:A mobile crane with tires on the bottom. The molile crane is a full-slewing crane that installs the lifting mechanism on a special chassis composed of heavy-duty tires and axles. Its upper structure is basically the same as that of a crawler crane. In order to ensure the stability of the fuselage during installation operations, the crane has four retractable outriggers. When hoisting, it is generally necessary to use the outriggers, increase the supporting surface, and level the fuselage to ensure the stability of the crane.

Keywords: mobile crane inverter

1.Introduction/Project Background/Application Scenario Introduction

Xiamen Songyu Container Terminal has a batch of rubber-tyred container gantry cranes (rated lifting capacity of 61 tons) with double-container operations, and its original electrical system has been in use for 14 years. Due to the aging of inverter components and functional degradation, etc., the IGBT is prone to abnormal faults such as overheating and overcurrent. In addition, the original system has been discontinued globally. The procurement of spare parts is difficult, the cycle is long and expensive, and the failure rate is high. The original electronic control system as a whole has been difficult to meet the efficient and stable operation requirements of the terminal.

Since the overall equipment adopts the original system, the inverters of our company need to pay attention to the following points in order to replace and transform them:

1. Adapt to the original PLC communication;

2. To achieve the operating performance of previous system;

3. To have an active rectification function and feed back electric energy.

2. Product and Solution introduction

2.1 Principle of mobile crane equipment

A mobile crane is a rubber-tyred gantry crane that uses a tire-type chassis to walk. It is a gantry crane with a gantry structure installed below with wheels that can rotate and walk. Its upper structures are basically the same.

In order to ensure the stability of the fuselage during installation operations, the crane is equipped with four retractable outriggers. On flat ground, there is no need for outriggers, and the tires alone can be used for walking. When transitioning, the outriggers are supported by hydraulic pressure and driving the tires to turn then realize direction changes.

It consists of two parts, the main beam and the outriggers. The main beam is the lifting operation part, which is equipped with trolley, lifting mechanism, etc. The outriggers are the supporting and walking parts, equipped with gantry, rotating tires and other structures.

Relying on its flexible advantages, mobile cranes are widely used in port terminals and are an important part of container terminals.

2.2 Introduction of our company's soluiton

2.2.1 Features

Our company configures GD800-96 active rectifiers with GD350-19 series hoisting industry-specific inverters for multi-transmission system applications. This scheme has been verified in many occasions, which can ensure the stability of the operation and the protection during the lifting process.

Goodrive350-19 series inverter is a new generation of hoisting dedicated inverter launched by INVT based on more than ten years of experience in the hoisting industry and combined with advanced control theory; it can be applied to port machinery equipment, factory hoisting equipment, construction machinery equipment, mining machinery equipment and other types of lifting equipment, excellent control performance, rich safety protection functions, strong expansion ability.

* Low frequency high torque: with PG vector control: 0Hz/200% (rated torque); space voltage vector: 0.5Hz/150% (rated torque)

* Good load adaptability: The control algorithm is optimized for lifting applications, the output torque can be adaptive according to the load situation, and good performance can be obtained both with no load and with load.

* Conical rotor motor Control: Adjust the magnetic flux for conical rotor motor characteristics. Realize rapid brake release and brake control, simplify debugging steps, and ensure equipment safety.

*Special brake logic: Brake logic control is integrated with torque verification. After the torque is established, brake release control is performed to ensure that the vehicle does not slip. Brake logic control supports starting direction and forward and reverse switching brake selection functions to meet various starting requirements. Requirements, good adaptability.

*Loose rope protection: avoid safety accidents caused by high-speed hoisting when the rope is slack, misoperation of the speed-up function, and rope failure.

*Stable lifting: when the wire rope is straightened at a high speed, the fast tide is limited to reduce the impact of the sudden load on the crane at the start of the lifting.

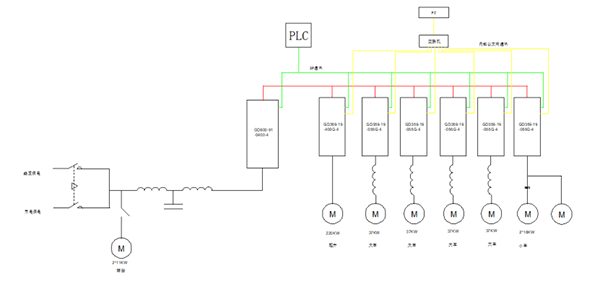

2.2.2 Scheme system diagram

2.2.3 Scheme configuration table

| Mechanism | model | quantity |

| Rectification | GD800-96-0400-4 | 1 |

| hoisting | GD350-19-400G-4 | 1 |

| gantry | GD350-19-055G-4-B | 4 |

| trolly | GD350-19-055G-4-B | 1 |

| communication card | EC-TX503 | 6 |

| EC-TX103 | 1 | |

| Ethernet card | EC-TX511B | 6 |

| PG card | EC-PG507-24 | 6 |

3.Product/Scheme Advantages

The advantages of INVT GD800-96+GD350-19 system configuration scheme are as follows:

1.The harmonic content on the grid side is low, and the total harmonic is less than 5%;

2.High power factor, power factor greater than 98%;

3.With hoisting macro application, it is specially aimed at hoisting conditions and has perfect protection;

4.With energy feedback, it can effectively recover the energy of the container during the lowering process;

5.Support a variety of extended functions, such as: support a variety of encoders, support a variety of communication functions, etc.

4. Customer benefits

On December 28, 2021, Songyu Wharf organized the completion acceptance of the transformation project of two gantry crane inverters. After passing multiple groups of rigorous tests on site, it was finally determined that the electronic control transformation using domestic INVT inverters had satisfactory results. After the transformation The performance of the whole machine fully meets the original design plan, and the transformation cost is far lower than that of imported frequency converters. After calculation, INVT's GD800-96 active rectifier product can save more than 60% of electricity.

5.On-site application video/picture

6.Conclusion

The application of INVT GD800-96 series rectifiers and GD350-19 series inverters in Songyu Wharf shows that INVT’s energy feedback solution can perfectly replace imported brand products, and has been recognized and affirmed by the owner. It is another manifestation of INVT's response to the national "carbon neutral" policy in the port industry.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.