Abstract: This article mainly introduced INVT GD5000 medium voltage drive applied to DD washer and described detailed information involving the structure, principle, process, feature of DD washer. The practical application shows good speed control performance and stability of INVT GD5000 3.3kV drives and it is worth promoting.

Keyword:INVT, GD5000 MVD, DD washer, Energy saving

1. Brief introduction

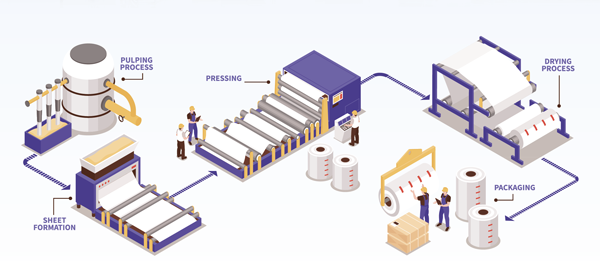

Pulp and paper making process

In the pulp and paper making process, the washing, screening, purification, bleaching, post bleaching washing and concentration processes have the highest energy, chemical consuption, and water and drainage volume. It is recommended to use the counterurrent washing process in this section to promote water conservation and emission reduction.

DD washer process

The Drum Displacer washer(DD washer) has designed in response to the demand for improved washing efficiency, reduced operating, maintenance and capital costs. Today the DD washer is widely accepted by pulp mills all over the world. The family of DD washers comprises machines that can be fed at low(from 3%to 6%,LCDD) or medium(from 8%to 11%, MCDD)consistency. The number of washing stages varies from one to four. Due to its unique segregated counter-current washing principle, a high washing efficiency can be reached. The design and the construction of the DD washer has been further developed, so that even higher displacement washing efficiency can be achieved and this excellent washing efficiency has been proven in the trial. The DD washer installation positions include brownstock washing, post-oxygen washing and bleach plant.

2. Project information and solution

2.1 DD washer information

Detailed motor parameters are list as follow:

Motor tag at site | Motor power(kW) | Motor voltage |

BSW Feed MC Pump | 630 | 3.3kV |

BS DD Washer | 355 | 3.3kV |

O2 MC Pump 1 | 800 | 3.3kV |

O2 Feed MC Pump 2 | 800 | 3.3kV |

Pump to Wenuri WP | 500 | 3.3kV |

Post O2 Feed MC Pump | 315 | 3.3kV |

Post O2 Feed MC Pump | 630 | 3.3kV |

Unbleached Tower Feed MC Pump1 | 710 | 3.3kV |

BSW Feed MC Pump | 18.5 | 380V |

BS DD Washer | 18.5 | 380V |

O2 Feed MC Pump 2 | 630 | 3.3kV |

Pump to Wenuri WP | 355 | 3.3kV |

Post O2 DD Washer | 800 | 3.3kV |

Post O2 MC Pump | 750 | 3.3kV |

O2 Feed MC Pump1 | 355 | 3.3kV |

Unbleached Tower Feed MC Pump1 | 630 | 3.3kV |

Post O2 DD Circulate Filtrate Pump | 900 | 3.3kV |

BS DD Circulation Filtrate Pump | 800 | 3.3kV |

BS DD Circulation Filtrate Pump | 18.5 | 380V |

Post O2 DD Circulate Filtrate Pump | 18.5 | 380V |

Table 1.DD washer motor list

2.2 System solution.

According to customer demand and considering load condition and uniform spare parts, the below VFDs are selected for this project.

VFD Model | Power | Rated Voltage | Rated Current | Quantity |

GD5000-A0800-3.3-S | 630kW | 3.3kV | 140A | 5 |

GD5000-A1250-3.3-S | 1000kW | 3.3kV | 219A | 10 |

GD5000-A1400-3.3-S | 1120kW | 3.3kV | 245A | 1 |

GD35 LVD panle | 22kW | 380V | 45A | 4 |

Table 2.VFDs for DD washer

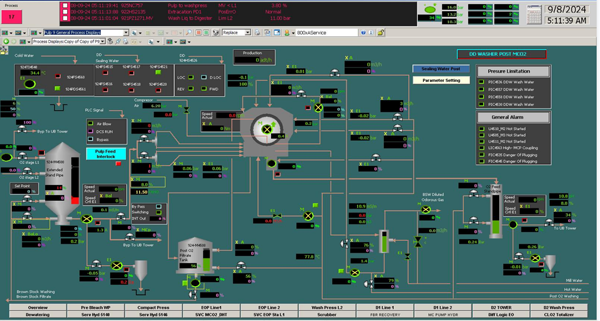

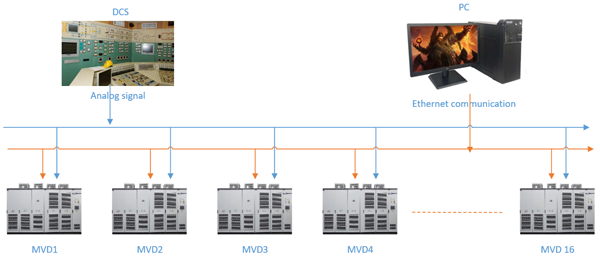

Main system diagram:

Control sketch diagram

DD washer site photo

MVDs in the machine roon

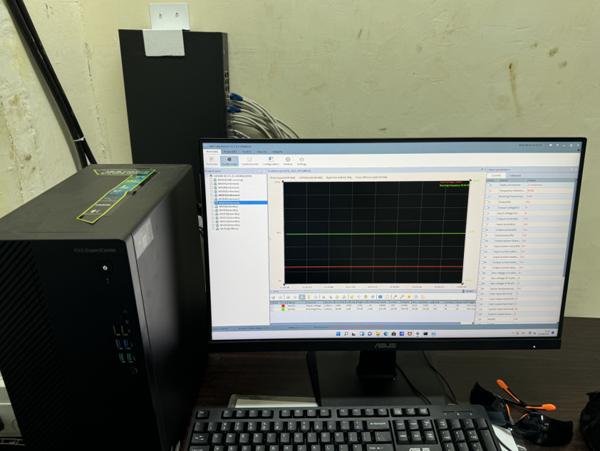

MVD monitoring via Ethernet

3 Application and Advantage

After using VFD, there are some major advantages as follow:

* Energy saving, chemical saving: The pumps and washer are running at optimal situation and can save energy.

* Wide range speed adjusted: Because VFD is a step-less speed regulation, the pump and washer can be run smoothly with wide speed range. It means that the speed adjusted can be elaboration and sensitive.

* Increase grid line power factor: The grid line power factor is over 0.97. It can increase efficiency of the grid power.

* Perfect output waveform: Output waveform is perfect, less than 2% of distortion.

* Prolong motor working life time: VFD can keep motor running at optimal situation.

4. Conclusion

Compared with old technology, the MVD driven method has many advantages. Especially significant energy saving. After commissioning, all the MVDs work very well, meet the process demand, customers are satisfied with INVT solution.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.