Abstract: Nowadays, Automation plays a key role in all over the industries. Due to the demand of using paper is growing day by day, efficiency and quality is need to be improved in the process of paper mill. Although, paper making involves the use of several different processes and machines. The slitter-rewinder is an essential part of any paper mill. Unwinding of large, main freshly produced rolls from paper making machine, cutting it into smaller length, and rewinding it to smaller rolls for delivery is the slitter-rewinder machine.

The basic concept is to used tension controller, nip reliving rider roll using PID proportional function, HMI, and PLC to out the process. The main idea is to automate the process to avoid paper breakage and bring in optimal time management and quality rewinding.

Keywords: AX72, DA200, Motion controller, Torque control, Paper Industry, INVT, Servo, Rewinder, Slitting machine, PLC, HMI

1. Introduction

Basic components of slitter-Rewinder

MACHINE PROCEDURE:

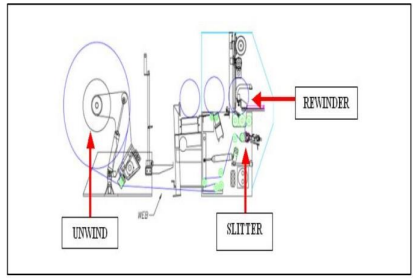

A paper slitter rewinding machine is a retrofitting machine that cuts the main large paper roll into small rolls that can be used for other purposes. Fig. 6 shows basic components of a slitter rewinder of paper machine.

The paper slitter rewinding machine consists of: A) Unwinding stage, B) Slitting stage, C) Rewinding or winding stage

A. Unwinding stage

This stage contains a stand to unwind, which is used to load and secure the main roll of paper. The roll would be held in place by the stand, which causes it to rotate around its central axis. The two extended ends of a shaft are clamped which retain the rolls that runs the entire length of the rolls on bearings in backside stand.

B. Slitting Stage

The slitting of webs into several small slits takes place during slitting point. The paper which is unwound is then carried over to a series of spread rollers and slitter head after leaving winding point. The slitter head is used to cut the web. The slitter head contains a series of rotating knives or razors. Depending on unit type, the required width of the slit is set in manual or automatic by adjusting knives position on the slitter head. There are rollers in front of the slitter head that which makes the sheet straight and ensures cuts in good quality.

C. Rewinding Stage

In this stage, rewound of rolls into required diameter of small cores is done in the rewind stand from slitter head. Factors like wound material and roll hardness, influence type of winder that is used in the specified situation. After slitter head, the rollers split the slit parts when they join the winding. It prevents the roll range of the sheet weaving back and forth in-between adjacent rolls.

2. Project information and Solution

2.1 Project information

Site information: Paper

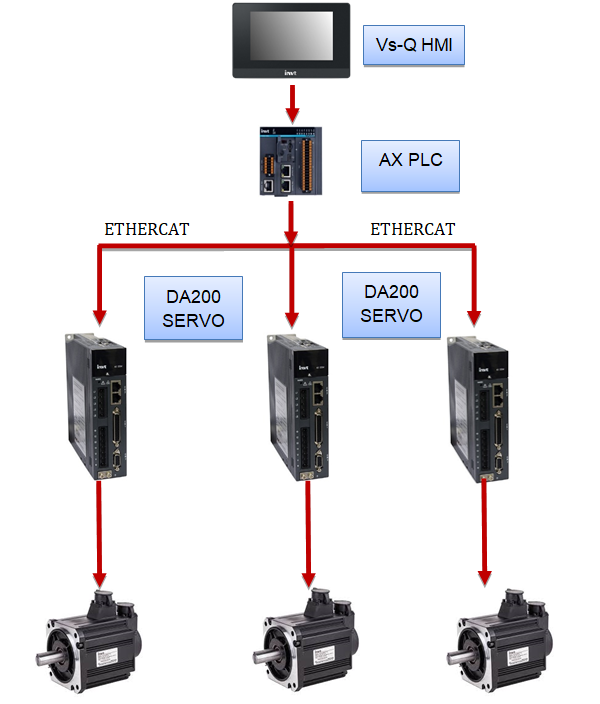

2.2 INVT solution

Product | Model no. | Qty | Application |

HMI | VS070QE | 1 | Operator Display |

PLC | AX72C-1608N | 1 | Controller |

SERVO | SV-DA200-2R0-4-S0/ SV-MM13-2R0E-4-1A0-1000 | 3 | Unwinder and Rewinder |

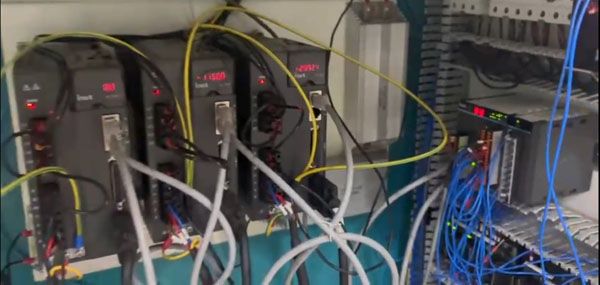

3. System commissioning

Control panels

4. Advantages and benefits

a. Improve production efficiency and improve Precision and consistency.

b. Reduce labor costs.

c. Strong compatibility and reduced waste.

d. Automatic diameter calculation and torque compensation

e. Increase the speed by 10% and can run up to 280 MPM.

5. Conclusion

INVT solution delivered significant performance improvements in terms of speed, quality, and efficiency. Machine speed and efficiency was radically increased by 10%, automatic diameter calculation and torque compensation from Ethercat communication leads faster response .

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.