Abstract:

Automatic tube filling machine is used to dispense and fill liquids with high viscosity into containers with high precision and speed. There are many types of head filling machines according to different filling principles, such as: 1 head servo driven piston filler, 1-head pump filler, 1-nozzle net weight filling machine, etc.

Keywords: AX72, Pulse logic, EtherCAT, E-CAM, Mark correction, High speed

1. Introduction

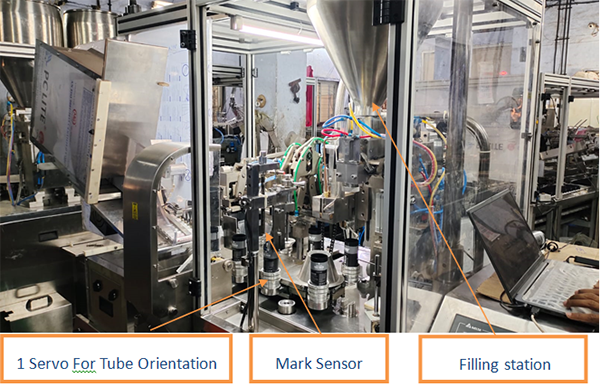

MACHINE PROCEDURE:

Fully Automatic Linear High Speed 19 Stations 1 Head Tube filling machine has following segments.

* Encoder:- 2500 ppr master encoder specify the speed as well as running angle on the machine. Based on the mechanical degree all operation like sector conveyor, Pushing of tubes, indexing, orientation, filling, sealing, coding then ejecting.

* Sector Conveyor:- It’s a servo driven conveyor based on E-CAM which can feed 1 tubes at a particular angle of encoder.

* Tube Pushing:- It’s a servo driven ball screw driven linear mechanical arrangement which is also start forward to push the tubes and return back to home for next cycle ,its also on E-CAM function.

* Indexer:- It’s a servo driven chain arrangement based on E-CAM which can move 1 tube holder in every stroke, its also start and stop at a particular angle of encoder.

* Orientation:- This machine has 1 orientation function which can ensure the tube faced on eye mark so that after filling the sealing and coding should proper.

* Filling :- It’s a servo driven piston arrangement based on E-CAM which can move to and fro motion to suck and fill in every stroke, its also start and stop at a particular angle of encoder. Filling Accuracy is ± 1%.

* Heating and sealing:- It’s the arrangement and heater temperature control on stand alone PID controller.

* Tube ejection: Automatic Filled Tube ejection at separate station. Empty Tube Feeding, ‘I’ Mark Orientation, Filling, Sealing, Crimping, Coding and filled Tube Ejector Automatically.

2. Project information and Solution

2.1 Project information

Site information: Pharma Company

2.2 INVT solution

Product | Model no. | Qty | Application |

AX72C-1608N | 1 | CONTROLLER | |

EXTENSION | AX-EM-1600D | 1 | CONTROLLER |

EXTENSION | AX-EM-0016P | 1 | CONTROLLER |

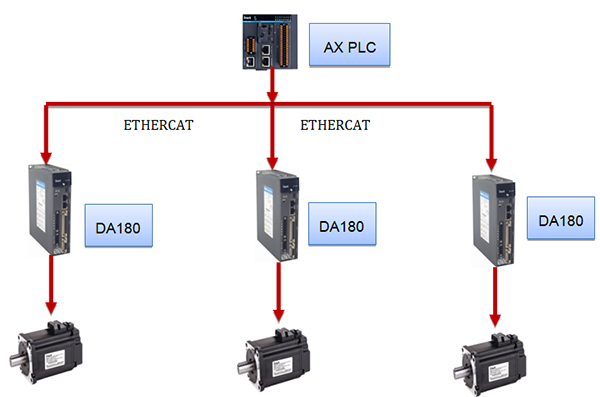

SERVO MOTOR | SV-ML06-0R7G-2-SA0-1000 | 1 | INDEXER |

SERVO DRIVE | SV-DA180-S4R5-NG0 | 1 | INDEXER |

SV-ML06-0R4G-2-SA0-1000 | 1 | FILLING AND PUSHER | |

SERVO DRIVE | DA180-S2R8-NG0 | 1 | FILLING AND PUSHER |

SERVO MOTOR | SV-ML06-0R2G-2-SA0 | 1 | ORIENTATION |

SERVO DRIVE | DA180-S2R8-NG0 | 1 | ORIENTATION |

2.3 System Configuration

2.4 System commissioning

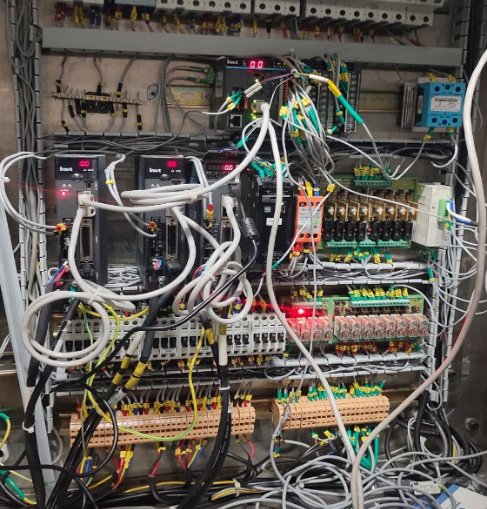

Control panels

3. Advantages and benefits

* The capability to work with different materials is the first advantage of a pharmaceutical tube filling and sealing machine. The machine is capable of using a variety of tubes. Utilizing this kind of equipment will considerably improve production efficiency and assure uniform product quantities, which will guarantee that your products are packaged consistently.

* Waste can be decreased by using a tube filling machine. It can precisely dispense diverse product kinds, such as creams and infusion bags, with product and filler. The filling device for pharmaceutical tubes can be fully automated.

* When filling pharmaceutical tubes, a tube filling machine is utilized to avoid mistakes and leaks. These tools can be configured to measure the precise quantity of the product and apply the proper seal to the tubes.

* Maximum Speed is 55 tubes for minute at accuracy of +-2%

* As its E-CAM based machine so user can modify the tube and head as per operator setting.

4. Conclusion

This Automatic tube filling machine is installed in pharma industry and performance, accuracy and stability all meet the process requirement. We have given INVT solution against omron motion controller.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.