Abstract: Cone crushers are a type of crushing equipment that play a crucial role in the processing of various materials in the mining, quarrying, and construction industries. They are designed to crush large rocks and ores into smaller fragments, which can then be further processed into finer particles. In this review, we provide an overview of the design, operation, and applications of cone crushers.

Keywords: GD200A, Crusher, Heavy Duty, SVC

I. Introduction

MACHINE PROCEDURE:-

* Feeding Stage: Stones are fed into the cone crusher. The feeding process ensures that the stones are delivered to the crusher in a regular and controlled manner. In this stage, large stones are prepared to be transformed into smaller pieces.

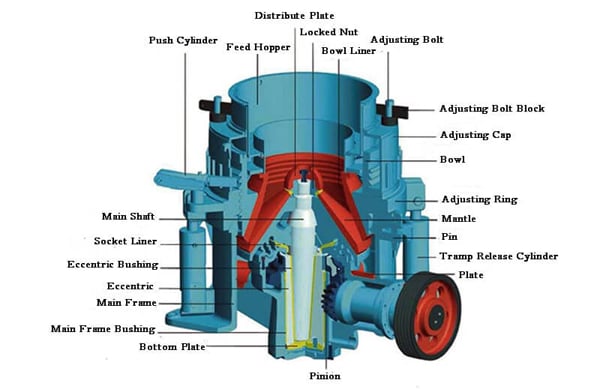

* Crushing Stage: The eccentric shaft in the cone crusher causes the crusher head to rotate. This rotational movement enables the stones to be crushed. Stones trapped in the gap between the conical head and the body are crushed and broken. The stones are fragmented through pressure and friction between the crusher head and the conical body.

* Screening Stage: The stones that have undergone the crushing process pass through holes at the bottom of the cone crusher. Depending on the sizes of these holes, stones of the desired size pass through the screening process, while unwanted larger pieces get caught in the screening. This step is crucial to obtain stones that meet specified standards.

2. Project information and Solution

2.1 Project information

Site information: Construction/Infra

2. 2 INVT solution

Product | Model no. | Qty | Application |

VFD | GD200A-220G/250P-4 | 1 | STONE CRUSHER |

3. Advantages and benefits

* Overload percentage is 150% for 1 minute, Heavy duty drive.

* It can sustain in such dusty environment due to quality of conformal coating.

* VFDs can improve the efficiency of the crusher by allowing the motor to operate at its optimal speed, reducing energy consumption and costs.

* VFDs can reduce maintenance costs by minimizing the need for frequent belt replacements and reducing the risk of overheating.

* VFDs can improve crusher performance by allowing for precise control over the motor speed, which can result in better material reduction and fewer issues with jamming and blockages.

4. Conclusion

cone crushers are a versatile and efficient type of crushing equipment that play a critical role in various industries. Understanding their design, operation, and applications can help engineers and operators optimize their performance and ensure reliable operation. INVT GD200A VFD is installed in stone crusher machine and performance and sustainability all meet the process requirement. We have given INVT solution against soft starter.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.