1. Project Background

In the fast-developing express delivery and packaging industries and other fields, the pursuit of high productivity and low operating costs of enterprises has been increasing, and in terms of laminating machines, the demand for them to be able to efficiently and accurately carry out laminating operations is also becoming increasingly prominent.

Paper laminating machine is composed of paper feeding mechanism, paper laminating mechanism and paper pressing mechanism, two wind heads are set side by side on the paper feeding mechanism, an intermediate positioning mechanism is set on the paper laminating mechanism, which divides the paper laminating mechanism into two paper paths, a wing-shaped spring plate is set on both sides of the paper laminating mechanism, and the intermediate positioning mechanism consists of an intermediate positioning guide block and a lifting mechanism.

2. Customer Needs

In order to solve the problems of low laminating precision and low productivity that exist in the traditional laminating method, the customer urgently needs to upgrade the system. Their needs:

* Improve the laminating precision

* Machine to adapt to a variety of processing board size and processing requirements

* Able to record the quantity of paper laminating for statistics and management.

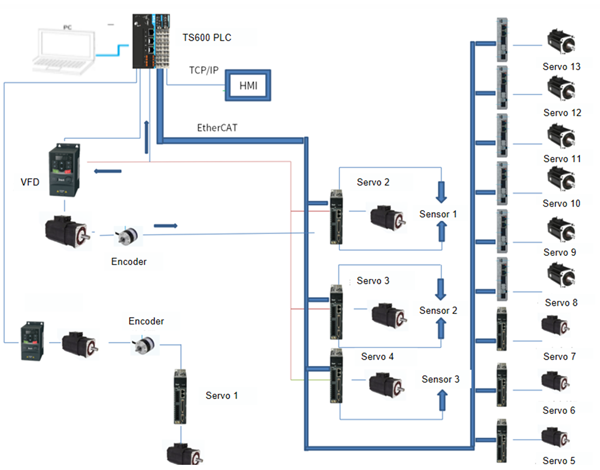

3. INVT Solution

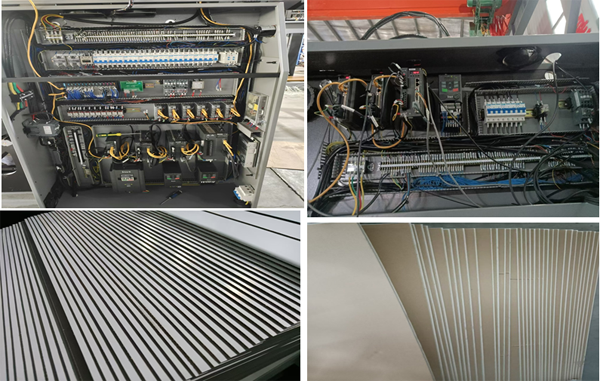

In order to meet customers' demands, INVT launches a new solution for fully automatic laminator: HMI, TS634 series PLC, GD20 series compact VFD and DA200 series high-performance servo drive. The solution adopts DA200 and TS634 control technology to ensure the stable and reliable operation of the laminator. EtherCAT bus control is adopted to solve the problem of pulse interference and ensure the positioning accuracy while improving the response speed. The order memory function realizes one-key order change, which is convenient and quick.

4. Customer Benefits

By applying INVT's fully automatic laminating machine solution, the customer obtains the following benefits:

4.1 Improvement of production efficiency: Compared with the traditional laminating method, this solution has one less motion controller, and the photoelectric signal is directly fed into the servo, which improves the processing speed by more than 10 times. In addition, the fully automatic laminating operation reduces manual operation and greatly improves production efficiency.

4.2 Improve the laminating precision: 95% laminating precision error is less than ± 0.5mm, the remaining 5% laminating precision error is less than ± 1.5mm, the length of different paper is automatically adjusted to ensure laminating precision.

4.3 Flexible to adapt to different needs: not subject to the processing of the size, the number of restrictions, to adapt to different processing needs.

4.4 Convenient statistics and management: the quantity counting function helps customers to carry out statistics and management.

By improving laminating precision and productivity, INVT laminator solutions meet the modern packaging industry's requirements for high efficiency and quality, helping customers achieve higher productivity and laminating quality.

At present, the packaging industry is in a period of great development. Through independent research and development, INVT continuously strengthens the functions of industrial automation products, provides high-quality solutions, improves the technical problems affecting the development of enterprises, and helps the printing and packaging industry to enter a brand-new era of high-efficiency processing.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.