Abstract: The adoption of medium voltage inverter on belt conveyor is the main point of safer and more reliable usage for mine belts. Based on the application comparison of hydraulic couplers and inverters on belt conveyors, and combined with the site working of belt conveyors and inverters in Vietnam coal mine, the article introduces relevant technology of belt conveyor systems and the application of medium voltage drives on the system.

Keywords: Belt conveyor, GD5000 inverter, Master-slave control, Power balance

1.Introduction

Belt conveyors are widely used in mines. It is necessary to install soft starting device according to the provisions of coal mine safety regulations. And hydraulic couplers, as well as CST, are currently used as the devices in most mines.

2.Principles and characteristics of belt conveyors

After driving the hub, the belt conveyor is working by friction traction and the belt leads the objection move on the supporting roller through the tension deformation and friction. Because the belt is elastic and stores a large number of potential energy when the belt conveyor stops and runs, it is necessary to start the belt conveyor flexibly. Currently, most mines apply hydraulic couplers as the softly-starting devices, but all disadvantages are presented when driving through mark inspection and users feedback, medium voltage inverters are taking the place of hydraulic couplers.

3.Advantages of medium voltage inverters

3.1 Soft starting.

The belt is driven by the motor slowly, to release storage energy slowly and reduce the impact during starting and stopping to the minimum, so it is nearly no damage to the belt;

3.2. Reduce the requirements of belt intensity.

The starting time of inverter can be adjusted in the range of 1~3600s and the time of belt is set in 60~200s according to the site work. Prolonging the starting time can reduce the requirements of belt intensity and initial equipment investment.

3.3 Torque balance of motor driving.

One-for-one control and master-slave or coordinating cabinet control is available;

3.4 Belt inspection.

Inspection at the low speed is required in the belt maintenance. Any speed in the range of 0~100% of the rated speed is available at non-load state because the variable frequency speed regulating system is the AC drive system of stepless speed regulation;

3.5 Stable starting with heavy loads.

The inverter can output 2.2 times of the rated torque at low frequency and is suitable for heavy load starting;

3.6 Automatic speed regulation.

The inverter can adjust the belt speed automatically according to the load weight with the cooperation of coal flow sensor, not only saving the energy, but also reduce the belt abrasion;

4.Site introductions

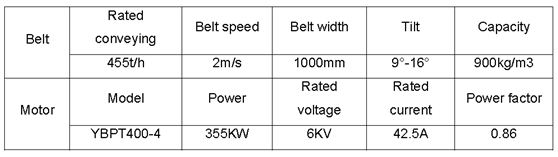

Vietnam ** coal mine is located in Vietnam. The parameters are as below:

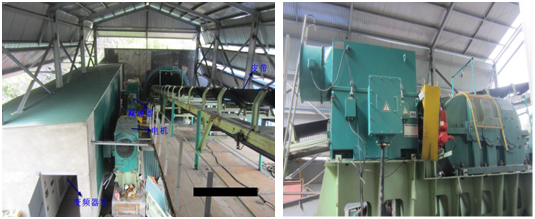

Picture 1 Site EnvironmentPicture 1 Site Environment

Picture 2 Coal ConveyingPicture 2 Coal Conveying

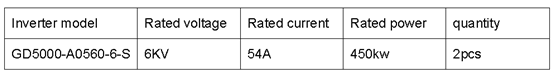

Picture 3 INVT medium voltage inverters

5. INVT GD5000 series medium voltage inverter

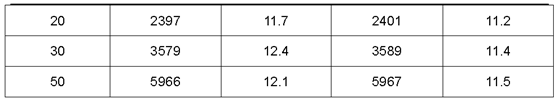

GD5000 series medium voltage variable frequency drives, the new generation speed-adjusting system, are indecently developed by INVT for medium performance sensorless vector control and VF control. The inverter has advantages of medium input quality, medium power factor and perfect power output, as well as medium control precision, fast dynamic torque response, low torque output torque, quick braking, and can be maintained in the front. The parameters of medium voltage inverters:

Operation: vector control

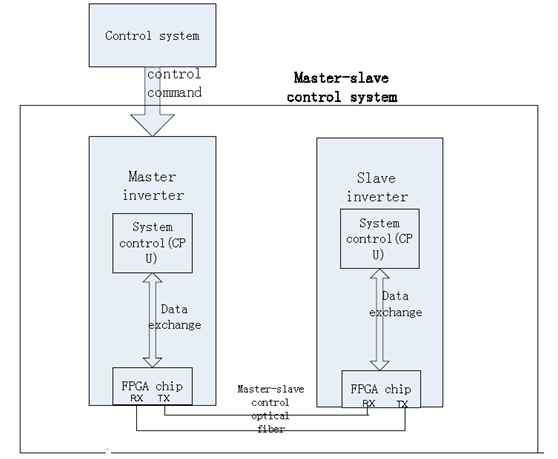

Control mode: master-slave

Picture 4: The medium voltage inverter master-slave control system drawing

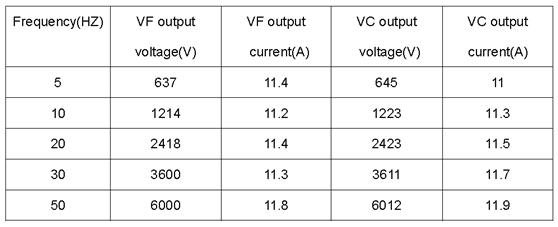

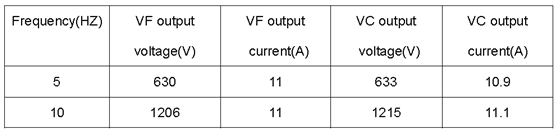

Commissioning sequence: VF operation——parameters autotuning——vector operation

Parameters of the master:

Parameters of the slave:

Autoturning result:

After the inspection, it is found that the parameters of two inverters, output voltage and current at same frequency in VF mode and vector mode are very close. So the operation is normal and the autoturning result is correct. After single-machine commissioning, it is necessary to begin master-slave commissioning. Operate from 0Hz to 50Hz and observe the output current, voltage, if the two inverters work normally and motor rotates stably, the commissioning is finished.

6. Conclusions

INVT GD5000 drives which applied in belt conveyors system, not only improve the production efficiency and system reliability, but also ensure easy maintenance and safe operation. It is proved that this speed-adjusting system can control the site working with mediumer efficiency, accurate automation and less energy consumption all around the time.

References

[1] GD5000 Series medium-voltage Variable Frequency Speed Control System Manual. Shenzhen Invt Electric CO., LTD.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.