Abstract: This paper introduces the application of INVT Goodrive5000 series medium voltage vector inverter in MVR system steam compressor, according to the steam pressure and temperature of the compressor speed PID automatic regulation, energy-saving and environmental protection.

Key words: Goodrive5000 series medium voltage vector inverter、MVR system、Environmental protection、Energy-saving

I. Introduction

MVR is short for Mechanical Vapor Recompression technology. MVR is an energy-saving technology that reuses the energy generated by its own secondary steam, thereby reducing the need for external energy. In this paper, INVT Goodrive5000 series medium voltage vector inverter in a customer MVR system field application as an example to introduce in detail.

II. The working principle of MVR

The theoretical basis of MVR is Boyle's law: V= k/p, that is, PV/T=K. This means that the pressure × volume/temperature of a given mass of gas = constant, which means that when the volume of gas decreases and the pressure increases, the temperature of the gas will also rise. According to this principle, when the thin secondary steam becomes smaller after compression, its temperature will rise and the pressure will rise, so as to realize the low temperature and low pressure steam into high temperature and high pressure steam, and then can be used as a heat source to heat the stock liquid that needs to be evaporated again, so as to achieve the purpose of recycling steam. The purpose of the MVR is to enhance the grade of the steam, not to create energy. Because steam compression is achieved by mechanical compressor, it is called mechanical vapor recompression technology (MVR). MVR is the evaporation (distillation) process of the secondary steam with the compressor compression, improve the temperature, pressure, as a heat source into the heat exchanger, heating need to be evaporated material. In this way, the original secondary steam to be abandoned will be fully used to replace fresh steam, and completely abandoned the cooling tower, greatly reducing the operating cost, really achieve environmental protection, energy saving and cost saving.

III. Field application background

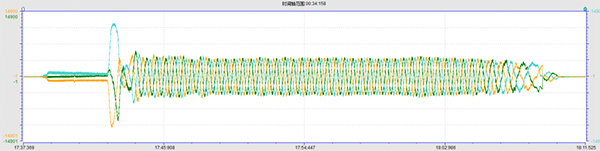

The customer's steam compressor is the core of the whole MVR system, with large power, the motor is directly connected to the compressor, such as power frequency direct start the load is too large to bear the power grid, and in the process of operation because of the working condition of the steam inlet pressure and outlet pressure of the compressor is greatly different, easy to appear system surge, power frequency operation not be effectively adjusted quickly, The whole system not work normally, resulting in production loss.

IV. INVT Solutions

In order to solve the problems encountered by the above customers in the field application, INVT provides the standard Goodrive5000 series medium voltage vector inverter + high voltage incoming switchgear solution.

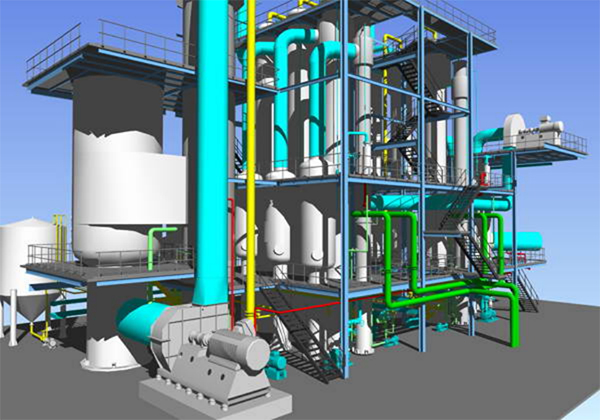

MVR system process figure

The above figure is the process of the MVR equipment. The raw material passes through the feed pump and enters the first-effect separator after passing through the feed preheat exchanger. The high-temperature steam at the exit of the steam compressor enters the first-effect heat exchanger, and the raw material flows into the first-effect heat exchanger through the forced circulation pump in the first-effect separator for heating and shunt to the second-effect separator. Raw materials in the two-effect separator through the forced circulation pump into the two-effect heat exchanger heating and shunt to the three-effect separator, raw materials in the three-effect separator through the forced circulation pump into the three-effect heat exchanger heating, the concentration reached as a product through the discharge pump into the finished product tank, concentration is not enough to return to the inlet. The condensate water formed by the heat exchanger of the first-effect separator and the second-effect separator is respectively pumped to other places through the drainage pump as production water. The secondary steam of the second-effect separator and the third-effect separator is used as the inlet steam recovery of the steam compressor. In the whole process, except that the temperature of the first startup is not enough, the inlet steam of the steam compressor needs to be provided. The heat energy of the whole process is generated by the steam compressor. After the normal start, the turbine compressor will breathe the secondary steam into the turbine compressor, which becomes heated steam after being pressurized, and then continuously circulates.

INVTGoodrive5000 series medium voltage vector inverter has the following advantages in MVR system:

1. The power frequency starting impulse current is large, which requires high capacity of the power grid. The frequency conversion starting has zero impact on the power grid.

2. Power frequency throttle adjustment precision is low, response speed is slow, easy to cause compressor surge. The use of frequency control can achieve high precision stepless speed control, the system response is fast, for the system pressure and temperature stability has significantly improved compared with the power frequency.

3. The use of frequency converter can improve the system efficiency and save energy greatly.

V. Goodrive5000 series high voltage

Goodrive5000 series medium voltage vector inverter is Shenzhen INVT Electric Co., LTD. Independent research、development、design and production of the second generation of medium voltage frequency control device.

Three nuclear control, high precision, high speed, ability strong anti-interference .

LVRT low-voltage electrical through technology. Effectively avoid downtime of the problems of power grid is not stable

Power unit bypass online technology, ensure the continuity of production

Internet remote monitoring technology, data wireless monitoring, remote fault diagnosis and management of equipment parameter

VI. Concluding Remarks

In modern industrial production, more and more attention to the importance of environmental protection and energy saving. Supporting the use of INVT high and low voltage inverter MVR system, while improving energy saving, increase the degree of automation of equipment, improve the stability of the whole system, can be widely used in chemical, pharmaceutical, paper, sewage treatment, seawater desalination and other industries, market prospects are very broad.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.