Abstract: This article introduces the application of INVT GD5000 series 380V input, 6/10kV output medium-voltage VFD in the test platform of Chengdu Compressor Factory.

1. Background

Due to the mature technology, simple system, high thermal efficiency, low unit power consumption, wide applicable pressure range, and the ability to achieve the required pressure regardless of the flow rate, piston compressors still have irreplaceable advantages in the petrochemical and natural gas industries.

Compressors above 185kW used in natural gas and shale gas extraction and transportation generally use 6/10kV medium-voltage motors, and most of them use medium-voltage soft starters. However, due to the small capacity of the power grid in some areas, the starting impact current of the soft starter is still between 2-4 times, and it is impossible to achieve load or frequent start and stop, so in recent years, the trend of medium-voltage frequency conversion replacing soft starters has become more and more obvious.

In addition, as the medium-voltage VFD DSP vector control technology becomes more mature, it can completely overcome the impact of piston compressor load fluctuations and meet the needs of low-frequency high-torque output and instantaneous torque response. Under certain working conditions where the flow needs to be adjusted, the return valve can be fully opened, and the flow can be adjusted by directly controlling the motor speed to achieve some energy-saving needs.

2. Project introduction

The Chengdu Compressor Factory of Jichai Power Plant of China National Petroleum Corporation is the only professional manufacturer of reciprocating piston compressors of "China Petroleum". It was founded in 1968. The factory has formed 5 major series of more than 100 specifications and models of compressor products, including ZTY series integral type, DTY series electric drive split type, R(C)TY series gas (oil) split type, CCTY series vehicle-mounted type, CKY series gas drilling booster, etc. The power range covers 100kW~7500kW, and the maximum working pressure is 70Mpa. It can meet the different needs of natural gas boosting, gathering and transportation, gas lift production, gas drilling, coal-bed methane production and transportation, gas storage gas injection production, gas injection production and oil production. The domestically developed 3500kW high-speed reciprocating piston compressor with the largest power independently developed is included in the major scientific and technological special project of the West-East Gas Transmission Line 2, a national key project.

In recent years, the sales of electric drive split compressors (compressors driven by electricity) have soared. The factory needs to build 2 production test platforms, which are mainly used for the assembly and commissioning of equipment before leaving the factory. One is 500kW, the other is 1000kW, and the motors include 6kV and 10kV specifications; the power ranges cover 185~500kW and 560~1000kW respectively.

Due to the high cost of applying for a 10kV medium-voltage power supply separately for the plant, but the 380V low-voltage power supply capacity is sufficient, our company proposed a direct AC380V input---6/10kV output system solution, which meets the actual needs of users to the greatest extent.

3. System solution

3.1 Main circuit solution

In response to the needs of this project, our company chose a one-to-one solution. The VFD can set the rated output voltage of the VFD according to the motor voltage level of the test platform through the "6kV/10kV motor selection" on the touch screen, thereby meeting the test needs. At the same time, the VFD is equipped with an over-voltage protection circuit, and the system is safe and reliable. The principle of the primary circuit is shown in the figure below:

Figure 1: The drag-and-drop solution

3.2 System principle

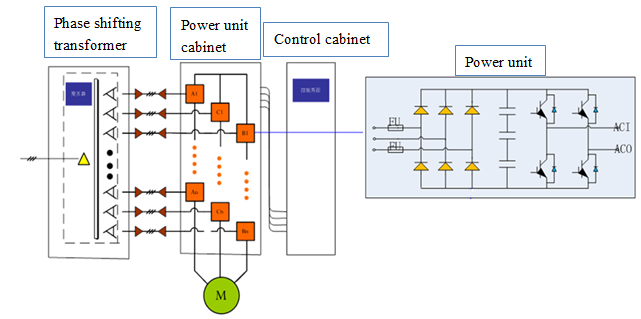

The VFD mainly consists of a dry-type phase-shifting rectifier isolation transformer cabinet, a power unit cabinet and a control cabinet. The main circuit part consists of a 380V three-phase power input connected to the primary side of the dry-type phase-shifting isolation transformer, and the secondary side consists of 8 groups per phase, a total of 24 groups of windings connected in a triangle connection (the purpose is to eliminate grid-side harmonics). The secondary side output voltage is 690V, which is connected to the power unit of the power unit cabinet as the input of the power unit. Each power unit is equivalent to a low-voltage VFD with three-phase input and single-phase output. Its maximum output voltage is also 690V, and then it is boosted to 6/10kV through the unit series connection to meet the voltage level requirements of the medium-voltage motor.

Since the power input is low-voltage 380V, when powered on, the 1000kW input current is above 3000A. Therefore, on the one hand, the 380V incoming main power output is directly connected to the primary side of the phase-shifting isolation transformer through the laminated copper bus-bar, and the input part is designed with a pre-charge buffer circuit. The customer needs to provide a 380V auxiliary power supply separately. When powered on, the VFD is pre-charged through the auxiliary power supply and buffer resistor. After the VFD sends a ready signal, the auxiliary power supply is automatically disconnected, and then the main power supply line switch is closed.

The system schematic is shown below:

Figure 2 System main circuit topology

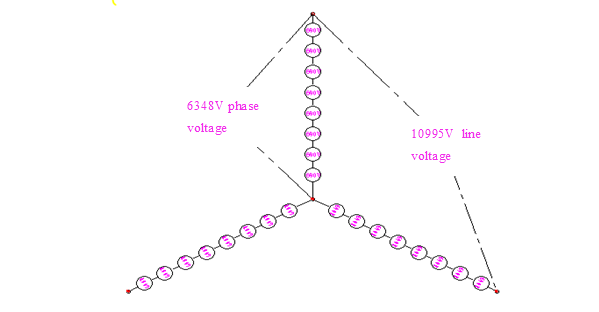

When the rated voltage of 10kV is required, the unit input voltage is 690V. After rectification and inversion, the output voltage can be output at a maximum of 1.15×690V according to the SVPWM method. The phase voltage value of 8 units in series is Un=1.15×690×8=6348V, and the line voltage is UL=6348V×1.732=10995V.

When the rated voltage of 6kV is required, the input voltage of each power unit is still 690V; by limiting the maximum conduction time of IGBT, the rated maximum output voltage is controlled at 400V, the phase voltage value of 8 units in series is Un=1.15×400×8=3680V, and the line voltage is UL=3680V×1.732=6374V.

By controlling the on and off frequency of IGBT, the speed regulation requirements of the motor in the range of 0.5~120HZ can be met.

Figure 3 Principle of unit series superposition (taking rated output 10kV as an example)

3.3 On-site picture

4. Comparison of solution advantages

Project | Indirect low-high | Low-High-High | Direct low-high |

Solution description | Traditional low-voltage VFD + step-up transformer | 380V/10kV step-up transformer + output voltage 6/10kV switchable high-high VFD | AC380V input 6/10kVoutput |

Harmonic pollution | 6-pulse rectification, THDi are over 20%; adding an input filter cannot meet national standards | 48-pulse rectification, THDi< 4%, meeting national standards | 48-pulse rectification, THDi< 4%, meeting national standards |

Motor requirements | 2-level output, high dv/dt, variable frequency motor required | 17-level output, low dv/dt, can use ordinary motors | 17-level output, low dv/dt, can use ordinary motors |

System structure | Complex. Need to add input and output reactors, filters, step-up transformer needs special customization | More complex, no input and output reactors or filters are required, but an additional line step-up transformer is required. | Simple. Just add a low voltage incoming power cabinet |

Control method | Poor. Since a step-up transformer is added between the VFD and the motor, it is impossible to accurately detect the motor parameters and only the traditional VVVF control method can be used. | Good. High-performance vector control can be achieved | Good. High-performance vector control can be achieved |

System efficiency | Poor, special step-up transformers have extremely low efficiency at low loads. | Poor. A step-up transformer is added to the front end, and an isolation transformer is added to the frequency converter, which reduces the overall efficiency. | High. No need to add an additional transformer. |

Cost | Low | High | High |

For the test platform, in order to meet the performance test and load regulation requirements under various working conditions and the power environment within the factory, the conclusion drawn from comprehensive evaluation is: the direct low-high solution issued by our company can best meet the actual needs of customers and the investment is the most reasonable.

5. Conclusion

Based on the actual use, the factory uses our company's medium-voltage VFD, which occupies a small space and is easy to install. When debugging, you only need to select the motor voltage level with one button, simply set the motor parameters and perform fast self-learning, and then you can perform high-performance vector control without adding unnecessary operating procedures.

The VFD can achieve 150% rated torque output at 0.5Hz of open-loop vector and 100ms torque response, which fully meets the performance requirements of the test platform. At the same time, the VFD can monitor the working status of each power unit online, including DC bus voltage, temperature, etc., and can provide fault prediction in time. Combined with the vigorous promotion of supporting customers, the application advantages of medium-voltage VFDs in petrochemical, natural gas, shale gas mining and transportation industries will become more and more obvious.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.