Taiyuan Iron & Steel (Group) Co., Ltd. Refractory Materials Co., Ltd. (hereinafter referred to as the company) is the subordinate refractory professional production plant of Taiyuan Iron and Steel (Group) Co., Ltd and one of the large-scale production enterprises of refractory industry in China. It was founded in 1931 with a floor area of 220,000 square meters, construction area of 105,000 square meters, the total equipment weight of 7423 tons, the annual sales income is stabilized at 50 million yuan.

After years of transformation and new construction, it has now developed into an integrated large refractory enterprise that integrates research and development, production, testing, marketing together and is the largest refractory enterprise in Shanxi Province. Based on Shanxi energy and heavy chemical industry base, the company makes full use of the rich quality refractory raw material resources in Shanxi Province. And the advanced production and testing equipment, strong technical strength, scientific management methods have improved the comprehensive production capacity, product quality and economic efficiency. It has the ability to provide the majority of users with the ordinary and special refractory products with more than 10 series, nearly 100 varieties and grades.

The company has advanced technology, excellent equipment and complete detection means. And it’s equipped with 6,000 tons static pressure molding machine, 8 sets of 1000,800,630 tons friction presses, a vibration molding press and 400 tons, 315 tons friction press; 4 sets of high-speed hot mixing machines, 2 high-temperature tunnel kilns, 1 shuttle kiln, 3 nitriding sintering furnaces, 1 rotary kiln; all kinds of broken crushing equipment, mixing equipment, mixer, weighing packaging equipment, testing equipment and so on.

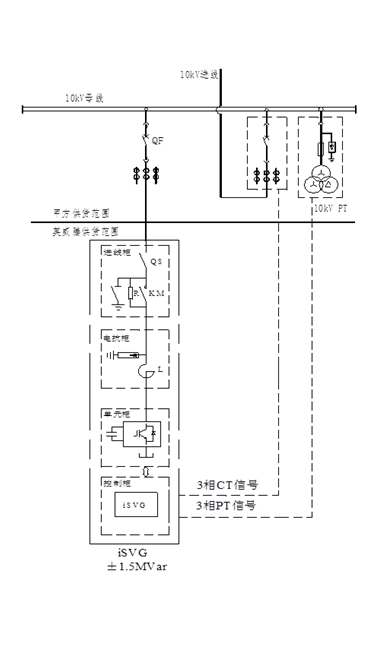

The total capacity of the project is 1.5MVar, 1 set 10kV dynamic reactive power compensation device, the device mainly includes: a set of rated capacity ± 1.5Mvar IGBT as the core part, the iSVG static reactive power generator and two sets of 10kV indoor high pressure reactive power compensation complete sets of equipment.

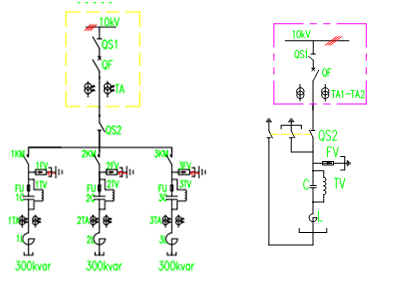

10kV indoor high voltage reactive power compensation complete sets of equipment include:

1. Device capacity: 900 kVar, the capacitor group: 300kVar +300kVar +300kVar, it’s divided into three groups, switching mode: tracking system reactive load changes, automatic matching switching capacitor group.

2. Device capacity: 600 kVar, the capacitor group: 300kVar +300kVar, it’s divided into two groups, switching mode: tracking system reactive load changes, automatic matching switching capacitor group.

Project implementation plan

Figure 1 iSVG system main wiring diagram

HVCS-10-900 HVCS-10-600

Figure 2 10kV indoor high voltage reactive power compensation complete sets of equipment wiring diagram

Figure 3 on-site iSVG picture

ISVG and 10kV indoor high voltage reactive power compensation device runs normally after being put into operation, which has meet the requirements of the plant buck power station for reactive power compensation device, and passed the acceptance of local Electric Power Bureau.

ISVG operating characteristics analysis:

1) Grid-connected voltage harmonics less than 1%

Adopting an unique DC voltage balance technology and multi-level vector control technology with smaller network voltage harmonics, excluding the background harmonics, devices and network voltage harmonics less than 1%

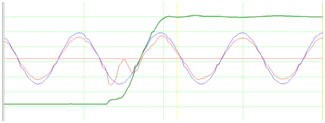

Figure 4 Harmonic voltage in parallel

2) Grid-connected current without impact

Adopt accurate grid synchronization technology and self-excitation start technology, without parallel current impact.

3) Vector control, the response speed is less than 5ms

Adopt vector control, the response time is less than 5ms. It has a better compensation effect for the rapid impact load and flicker.

Figure 5 Inductive to capacitive current step response

4) Compensation function diversification

It has reactive power compensation, harmonic compensation, regulator compensation, three-phase unbalance compensation and other functions

5) Multiple protection function

It has 17 protection functions to ensure the safe operation of equipment. Including over-voltage protection of the power grid, undervoltage protection of the power grid, unbalanced protection of the power grid, lack phase protection of the power grid, total over-voltage protection of the DC side, unbalanced protection of the DC side voltage, overload protection,etc.

6) Positive maintenance structure design

Adopt positive maintenance, equipment is installed on the wall, which has greatly saved the equipment floor area, and is convenient for user maintenance and repairing.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.