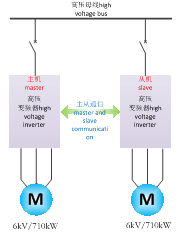

The annual output of coal of a coal company of Shanxi Jincheng Anthracite Coal Mining Group is 600,000 tons, the belt conveyor in the coal outlet is driven by two sets 6kV / 710kW asynchronous motors. The enterprise originally adopts soft starters and hydraulic couplers to solve the problem of motor start and speed control, but there are still a lot of drawbacks. Soft starter will produce a large number of harmonics, hydraulic coupling has high failure rate with large maintenance works, and multi-motor drive is difficult to adopt liquid coupling to solve the power balance problem between two motors.

Schematic plan

Benefit analysis

Master and slave control to achieve the power balance of two motors;

Realize the soft start and soft stop of belt conveyor, without impact current, reduce the damage to belt;

Low frequency large torque characteristics of the mv vfd to meet the heavy load start of belt conveyor;

Equipment maintenance cycle is extended, maintenance costs is reduced;

System efficiency is improved with certain energy saving effect.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.