Abstract: This paper mainly introduces the advantages of high control precision, high system stability and flexible user operation for using the manipulator control scheme of INVT DA200 high performance AC servo system. The excellent positioning accuracy and industry-leading speed response of INVT DA200 servo have won the customer's approval.

Keywords: INVT DA200, six-axis manipulator, positioning accuracy, high stability

1. Preface

Manipulator is an automatic device that imitates human hand movements, performs automatic crawling, moving, and operating according to a given procedure, track, and requirements. It is widely used in high temperature, high pressure, dust, flammable, explosive, radioactive and other harsh environments, as well as bulky, monotonous, frequent operation to replace human operations.

Manipulator is an important branch of industrial robot. It is characterized by programming to complete various expected tasks, and it has the advantages of human and machine both in structure and performance, which has particularly reflected the human intelligence and adaptability. Manipulator is a multifunctional machine that can automatically position control and reprogram to change, and has multiple degrees of freedom that can be used to carry objects and complete works in different environments. The operation accuracy of manipulator and ability to complete works in various environments endow it a broad development prospect in various national economic fields.

2. The main structure introduction of manipulator

According to the drive mode, the type of manipulator can be divided into mechanical, pneumatic, hydraulic, electric manipulator; according to the application scope, it can be divided into special manipulator and general manipulator; according to the movement track, it can be divided into point control and continuous track control manipulator and so on.

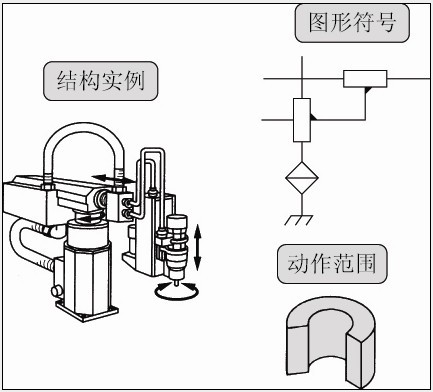

2.1 Cylindrical coordinate type robot

Figure 1

As shown in figure 1, the robot consists of a rotation and two translations. The entire column can be rotated, the arm can rise or fall along the column, and the arm can be extended or retracted. So the radius of rotation will change along with the work requirements.

2. 2 Ball coordinate type robot

figure 2

As shown in Fig. 2, C is the rotation center of the arm, which can be elongated and shortened, and the rotation center can also be rotated. The action scope should be a hollow ball, because the arm is not ideal to sweep a circle, so the ball is a broken one. Compared to other structures, this structure is easier to extend into the inside of upper and lower inclined holes and we should give priority to the ball coordinate robot with this demand.

2.3 Cartesian Coordinate Robot

figure 3

As shown in Fig. 3, the robot consists of two mutually perpendicular rails, on which there is a guide rail perpendicular to the two vertical rails, forming a three-dimensional system of rectangular coordinates, x, y and z axis. The robot has a very high accuracy due to its simple structure (no rotation and swing), and the track calculation method in the controller is also very simple. With a large work scope, it can be used as a high-altitude moving truck, and do straight line sending movement for furnace or other cavity equipment.

The coordinate measuring machine is also a cartesian coordinate robot.

2. 4 Parallel robot

figure 4

This is a new type structure robot, through the composite movement of each piece, it gives the end moving track to complete different types operations. The robot is characterized by good rigidity, and completing some functions of CNC machine tools, so it is also known as parallel machine tools.

At present, there are prototype to complete the complex surface processing, especially the fine processing, it is a new form of CNC machine tools and also a kind of robot function expansion. But its control calculation is very complex, the work scope is also very small, and its accuracy is lower than current CNC machine tools.

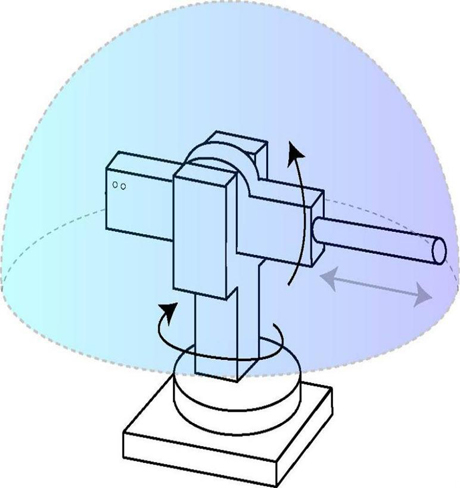

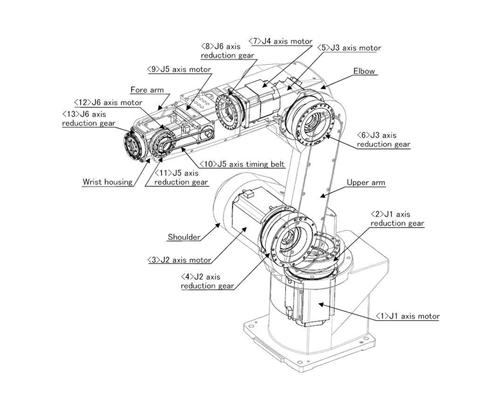

2. 5 Six - axis articulated robot

figure 5

Articulated robot is mainly made up of rotation and rotational degrees of freedom, it can be regarded as anthropomorphic arm structure. The part from the elbow to arm roots is known as upper arm, and the part from the elbow to wrist is known as forearm. This structure is the most effective for determining the position and attitude of three-dimensional space. It has a good adaptability for a variety of homework, the disadvantage is the complex coordinate calculation and control and difficulty of achieving high accuracy.

3. Application scheme introduction

3.1 The overall structure of equipment:

figure 6

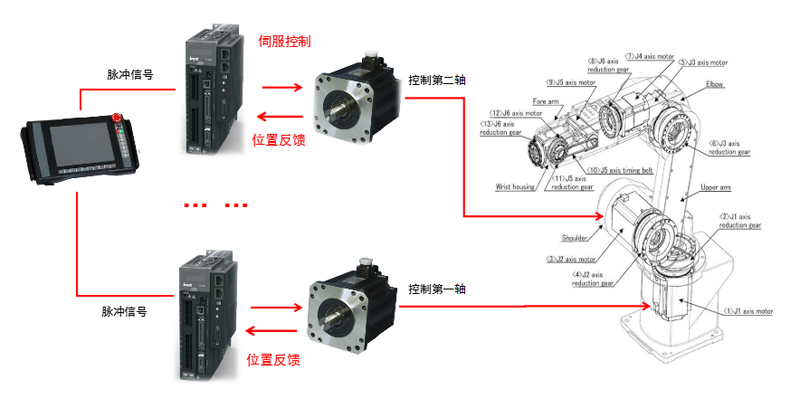

3.2 Electrical system composition diagram:

The customer has used total 6 sets of INVT DA200 high-performance AC servo system controlled by INVT intelligent controller.

DA200 is the star servo products that INVT strives to build with leap-type progress performance. DA200 speed response up to 2.0kHz, a variety of advanced algorithms, strong vibration suppression ability, rapid target command tracking speed, high positioning accuracy, built-in electronic cam, point control and other functions, simple debugging, suitable for any articulated robot controller.

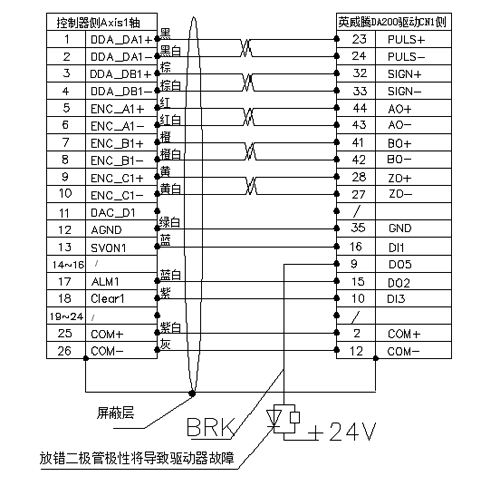

Electrical schematic diagram is shown in the following figure :

figure 7

The specific wiring mode:

Wiring requirements: connection from the system to driver requires a twisted 2*8 shielded cable. The brake system adopts 1*2 shielded cables to connect to brake stopping plate, the shells should be well connected to shielding layer. AGND in the controller side should be connected to the servo's GND, otherwise it may cause damage to the controller hardware.

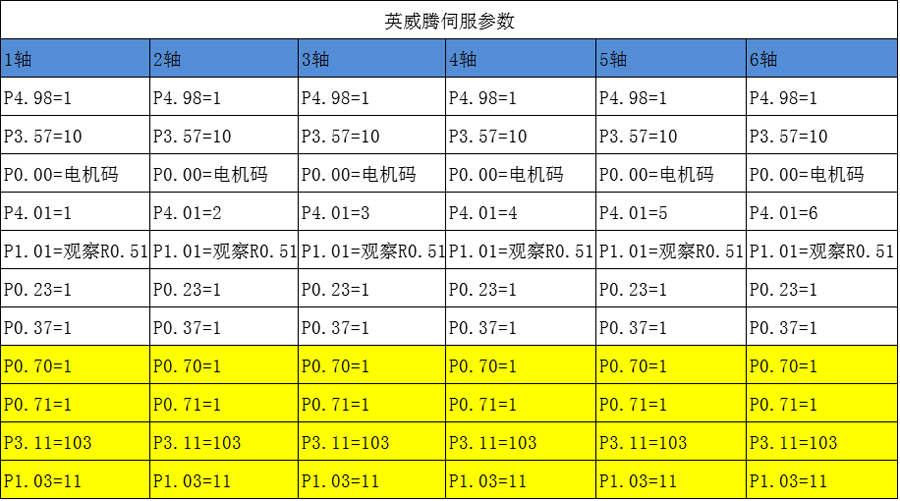

3.3 Parameter debugging

figure 9

nertia, observe the filling of R0.51 or through P1.04 self - learning. Control it not to exceed 2000.

Rigidity can be adjusted as needed, but each axis must be kept consistent.

4. Program summary

The manipulator control program of INVT DA200 high-performance AC servo system has the advantages of high control precision, high system stability and flexible user operation, which can be widely used in various industrial automation field, creating value for customers and improving equipment efficiency.

4.1 The robot development has a higher accuracy requirement for repeated positioning of device and it has reached ± 0.03mm high precision requirements, DA200 has excellent positioning accuracy, repeated positioning accuracy has reached ± 0.01mm, which can fully meet the high precision needs of robot.

4.2 After the demonstration of robot, each axis records the passing route in the respective memory. The recording position is reached when it occurs again. This is the basic principle of repetitive reproduction of robot. The excellent performance of INVT DA200 servo system has fully ensured the flexibility and accuracy of robot movement, and this is the pursuit of repeated positioning of robot movement.

4.3 DA200 is equipped with automatic gain adjustment, it’s convenient and quick to adjust each articulation servo performance to the best.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.