I. Introduction

The major processes of brush making machines are molding, drilling and filling.

1) A brush is a common tool with bristles, wire or other filaments. It generally consists of a handle or block to which filaments are affixed in either a parallel or perpendicular orientation, depending on the way the brush is to be gripped during use.

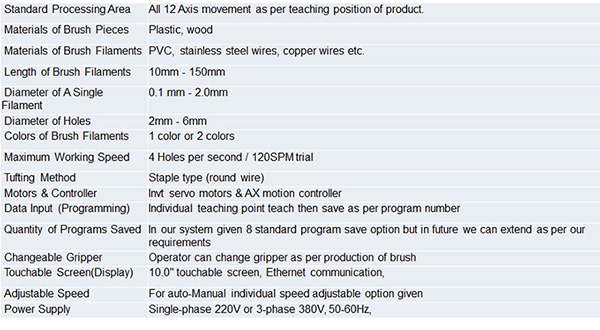

2) In this BSBM22-01 machine two head for drilling and one mechanism for filling of filaments. In this normally made flat surface as well as inclined surface types brush.

3) There are three grippers installed on worktable. When the machine is working, in turn, it always processes on two grippers only, another gripper is left unprocessed, so that operator could pick out the finished brush from it and put in another brush block to be processed.

4) X-axis two servo motor working simultaneously forward-reverse direction, Z-axis two servo motor working for up-down movement, R-axis two servo motor for incline or angle movement.

5) H-axis continue move in forward direction for head position up-down as well as filaments and wire fitting in hole. SL axis use to move y-coordinate, Y-axis use to move whole system in Y-coordinate.

6) B axis three servo only use in special type of job and front-rear type brush filling.

7) Two spindle motor use for drilling and operated through GD10 Invt make drive.

II. Project information and Solution

1. Project information

Site information: Customer work in CNC as well as brush making machine in Ahmedabad.

Brush Making Machine : Used 12 axis system for complete application running.

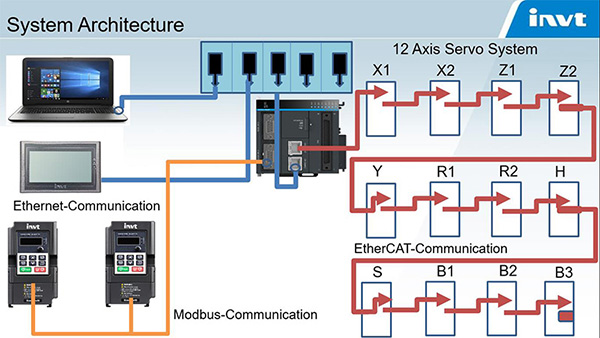

Schematic flow diagram of INVT automation product

2. INVT solution

Application | Motor/PLC/HMI | Inverter/Servo | Quantity |

H-Axis | SV-MM13-3R0E-4-1A2-1000 | SV-DA200-3R0-2-N0 | 1 |

X-Axis | SV-ML06-0R7G-2-9A0-1000 | SV-DA200-0R7-2-NO | 2 |

Y-Axis | SV-ML06-0R7G-2-9A0-1000 | SV-DA200-0R7-2-NO | 1 |

SL-Axis | SV-ML06-0R7G-2-9A0-1000 | SV-DA200-0R7-2-NO | 1 |

B-Axis | SV-ML06-0R4G-2-9A0-1000 | SV-DA200-0R4-2-NO | 3 |

Z-Axis | SV-ML08-0R7G-2-9A2-1000 | SV-DA200-0R7-2-NO | 2 |

R-Axis | SV-ML08-0R7G-2-9A2-1000 | SV-DA200-0R7-2-NO | 2 |

Spindle | Spindle Motor | GD10-2R2G-S2-B | 2 |

AX-PLC | AX70-C-1608P | - | 1 |

HMI | VS-102HCS | - | 1 |

III. System commissioning

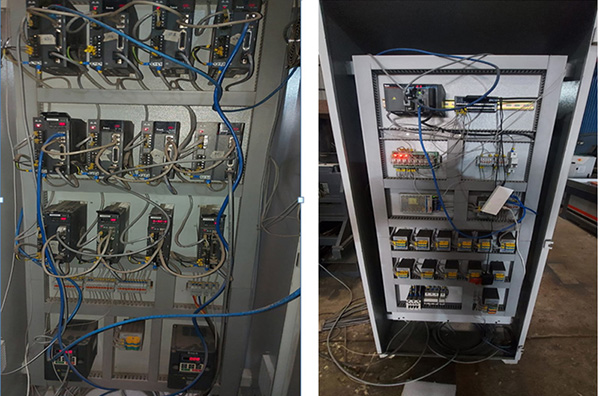

Control panels

Final product

IV. Advantages and benefits

• 12 axes system work with smooth operation

• All servo work in EtherCAT communication

• Accuracy too much high.

V. Conclusion

As per study and application execution, In these industries multiple axis type of machines for brush making application. In our system total 12 axis servo system used and every axis play an important role for better production. In this system 120stroke per minutes trial taken and average production is 700 brushes in 12 hours per day.

VI. Future Scope

Our system we can implement on 2 axes to 12 axes and more as per customer requirements. These type of logic and system use in multiple applications.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.