Abstract: Your grinding machine involves a process of material removal in the form of minute chips by the cutting action of numerous abrasive particles bonded together in the form of a grinding wheel. The cutting action takes place when you feed the work-piece against a revolving grinding wheel.

A Surface Grinding Machine is a versatile and essential tool used in the manufacturing and metalworking industries to achieve precise and smooth surfaces on workpieces. It is capable of removing material from the surface of a workpiece to create a flat, smooth, and accurately finished product. The machine uses an abrasive wheel or grinding wheel to perform the grinding process. Surface grinding machines are widely used in various applications, from producing high-precision parts for machinery to finishing surfaces of different materials like metals, ceramics, and plastics.

Keywords: IVC1L PLC , DA200 Servo set , GD10 VFD

1. Introduction

* MACHINE PROCEDURE:-

In this machine there are process involved–

1 Grinder unit – It is basically a unit which used to run grinder by the help of motor which runs continuously on single speed.

2. Job left & right unit – In this unit basic work is to move job unit in left & right movement where grinder fixed in one place and by the help of servo movement in left & right job grinds done.

3. Job forward & reverse unit – In this unit basic work is to move job unit in forward & reverse movement where grinder fixed in one place and by the help of VFD movement in forward & reverse job grinds done. In every cycle job comes forward in specific length and after completing grinding process completed in auto mode.

4. All the functions given in autocycle and manual mode.

Surface Grinding is a manufacturing process which moves or grinding wheel relative a surface in a plane while a grinding wheel contacts the surface and removes a minute amount of material, such that a flat surface is created. The term surface grinding designates any process which accurately processes or grinds a surface.

Surface grinding methods include: horizontal-spindle, vertical-spindle, vertical spindle rotary grinding, horizontal spindle single disk, and vertical swivel head grinding.

2. Project information and Solution

2.1 Project information

Site information: Surface grinder machine manufacturing company.

2.2 Customer Demand

Main concern of customer is of accuracy, cost effective, ease to operate solution & speed.

We have given solution with accuracy ease to operate & cost effective with INVT PLC, VFD & SERVO DRIVE.

As customer need to run same cycle process with different speed so we remove HMI for making it cost efficient and fix all data in PLC so that it will more easier and cost effective.

DA200 servo drive doing operation without jerk in forward & reverse motion because of that job is grinding safe from corners. Because customer need less area of movement so that production rises.

2.3 INVT solution

Product | Model no. | Qty | Application |

PLC | IVC1L3624MAT | 1 | CONTROLLER |

SERVO SET | SV-DA200-2R0-4-E0 | 1 | SLIDER FORWARD & REVERSE |

VFD | GD10-1R5G-4-B

| 1 | SLIDER LEFT & RIGHT |

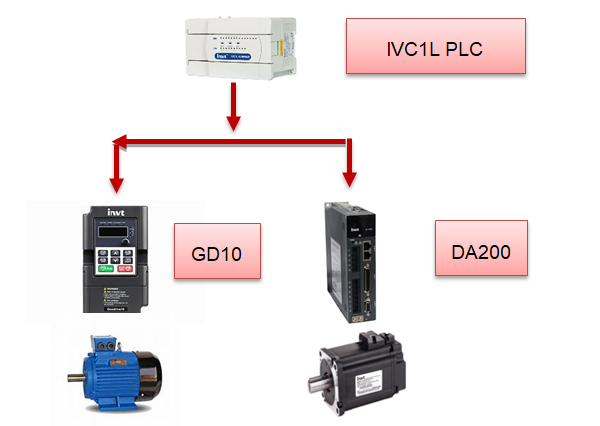

System Configuration:-

3. System commissioning

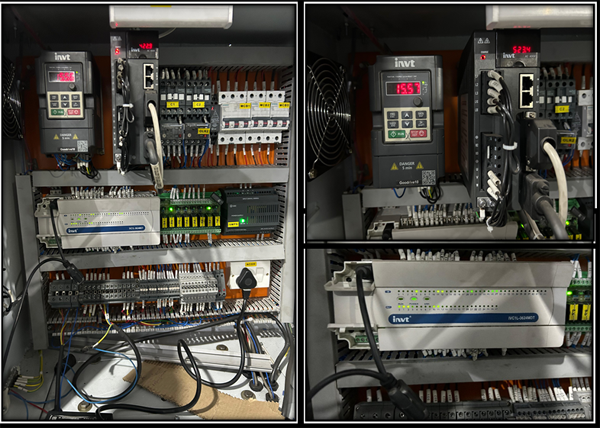

Control panels

4. Advantages and benefits

• Provides high accuracy and precision in producing flat surfaces.

• Capable of removing a significant amount of material in a short time, increasing productivity.

• Versatile and suitable for grinding various materials, including metals, ceramics, and composites.

• Can achieve smooth surface finishes, improving the appearance and functionality of the workpiece.

• Suitable for both small and large-scale production, making it cost-effective for various industries.

• Easy to operate and requires minimal operator skill, reducing the need for extensive training.

• The machine can be automated for repetitive tasks, enhancing efficiency and consistency.

5. Conclusion

IVC1L, Da200 servo drive and GD10 VFD are all used to operate & collect all data of machine to meet the process requirement. INVT has given Cost effective solution in Surface grinding application in India and machine is successfully running with customer satisfaction.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.