Abstract: This paper introduces the application of BPJ1 series explosion-proof inverter from Shenzhen INVT Electric Co., Ltd. used for the conveyor belt in mining. In the project, two BPJ1 inverters drive two asynchronous motors to keep the power balance in one control system. After replaced the star-delta system to inverter, the working efficiency of conveyor belt becomes higher, and start smoothly.

Keywords: BPJ1, conveyor belt, explosion-proof

1.Instruction

The conveyor belt is important transportation equipment in the mining. Only keep the conveyor belt stable operation, ensure the safety and then it can transfer the coal to ground and produce profit.

As we knew in the mining industry, explosion protection is the necessary. All of the equipments used in mining must meet the requirement of MA certification.

INVT BPJ1 series have passed the strict test from MA Center, Mining Products Safety Approval and Certification Center (MA Center) is independent legal entity organization authorized by State Administration of Work Safety (SAWS), completely meet the requirements of electrical devices used under coal mines and widely apply to conveying, hoisting, ventilating and power devices.

2.Project introduction

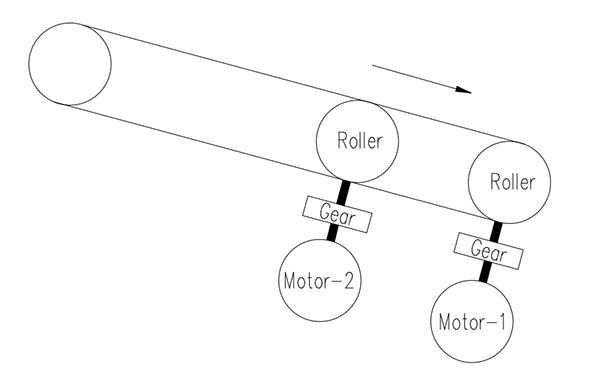

The project is a downward belt conveyor, included two asynchronous motors for driving. PLC is the main controller for deal with all of the signals, keep the safety and operation. The structure is as the following figure.

Figure 1: Conveyor belt structure

There are two kinds of explosion-proof inverters for conveyor belt, generally 2-quadrant and 4-quadrant inverters are used for the upward and horizontal direction equipments. For the downward conveyor belt, 4-quadrant inverter will be better. Because when the running direction is downward, sometime it will appear the regenerative energy, INVT supply the 4-quadrant explosion-proof inverter for this kind application. In the regenerative status, the energy will be sent to electric grid by 4-quadrant inverter, adopting this way can save energy and improve the working efficiency. For the 2-quadrant equipment, add another DBU and the braking resistor to consume the energy is necessary, but for the mining industry, it’s not a safe method.

3.The system solution

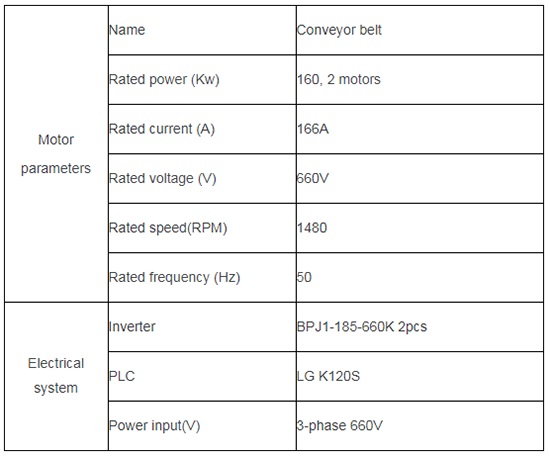

(1) System parameters:

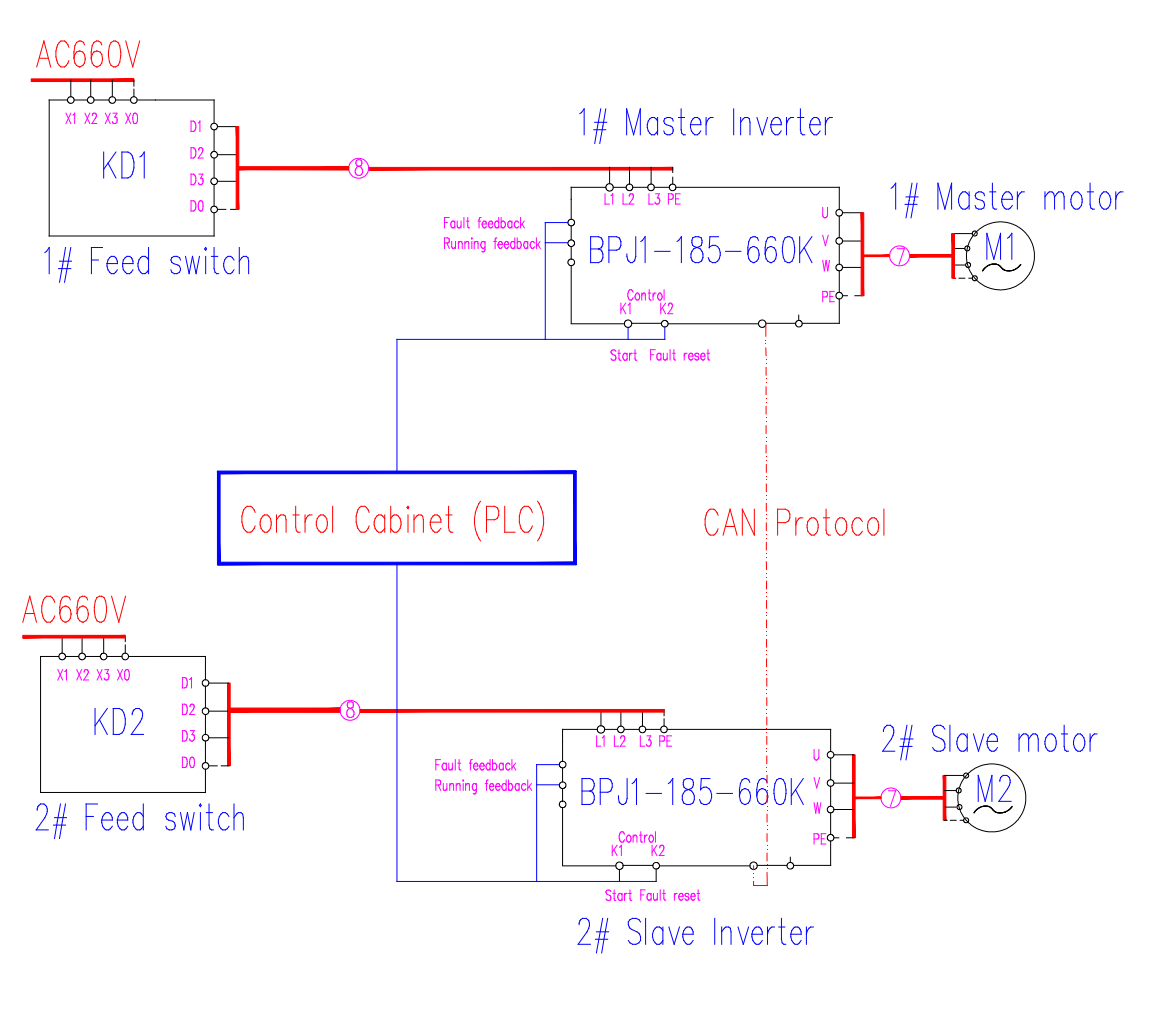

(2) Wiring diagram

During the system, PLC sends the speed setting signal to inverter by analog output, and controls the start /stop by digital output, then receives other external sensor, protection signal, fault output signal etc.

We can see the communication cable between the master and slave inverters, it’s used for the master-slave control and power balance function. In this situation, the internal software of BPJ1 series can detect the output torque of each inverter, calculate the output frequency.

Under master-slave control mode, master inverter control mode is speed control, and it receives the speed given signal from PLC; slave inverter communicates with master by the CAN protocol, and adopts the torque control mode, torque given signal is from internal algorithm after calculated the information from master inverter.

This master-slave function is the special characteristic of INVT drive, adopted in many applications such as the hoists, conveyor belt, transporter, winches and other equipments.

4.Typical case

BPJ1 series for mining conveyor belt in Vietnam.

This is an underground project in mining industry, all of the electric equipments are installed in the explosion-proof case.

Figure 3: Mining entrance and conveyor belt

Figure 4: BPJ1 series inverter

Advantages of the project

● Start smoothly in order to reduce the voltage spike to motor, reduce the mechanical impact, prolong the lifetime of equipment.

● Perfect master-slave control function realizes the power balance of multiple motors, protect the motor shaft and gear box.

● The motor adjustment in accordance with practical conditions brings significant energy saving effect.

● The design of ±15% wide power grid meets the requirements of the grid under severe environment.

● Meet the special requirement and explosion-proof certification in mining.

● Release the working task of control system, internal software calculate by its own hardware resource, improve the reliable operation of entire system.

5. Conclusions

This paper introduces the application features and advantages of BPJ1 series inverters in this case, through the actual application in the mining and analyzes the variable frequency speed regulator solution for conveyor belt. The site application shows that if select reasonable solution and INVT suitable, excellent product, better performance, stable working status, and safe operation are available.

Reference:

[1] Operation manual of BPJ1 series inverter of Shenzhen INVT Electric Co., Ltd.

[2] Operation manual of CHV100A of Shenzhen INVT Electric Co., Ltd.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.