Abstract: This paper mainly introduces INVT servo with its high accuracy, high response, high value and customized service, is successfully used in LED machines, it has won a high degree of customer recognition.

Keywords: INVT servo; positional accuracy; response speed; Speed observer

1 Project background

Shenzhen is an important production base and trade center of the national LED, and has a complete industrial chain and supporting capacity. In the fierce market competition, the company has been struggling with price and efficiency. In this context, Shenzhen a company's core products SMD - LED automatic spectral machine, naturally became the object of innovation, spectral machine is the core of the system - a part of the servo system has become the first to improve. INVT has been successfully shortlisted in DA200 servo and has achieved good results in the test with its many years of professional experience and popularity in the field of industrial automation.

With the increasing production efficiency, the original 40k/h spectrometer can no longer meet the market demand. Customers need faster speed and higher stability to meet production needs. After understanding the technology and the needs of customers, aimed at the characteristics of large rotary inertia, high requirements for rigid, INVT technical personnel through scientific calculations, groundbreaking for the industry have customized special motor, and use the DA200 series high-performance servo drive to meet and exceed customer expectations. The INVT servo is impressed by its high response speed, rich I/O function, powerful debugging software and other features.

2 Project alternatives

2.1 Servo selection and characteristic explanation

The LED splitter requires very strict position accuracy and response time. In the whole machine table, the key has two stations: the rotary axis and the detection axis. The rotation axis requires high rigidity, high speed and high response, while other servo brands choose the motor of 750W light inertia, and the space of rigid lifting is limited. INVT technical personnel through scientific calculations, groundbreaking customized special motors for the industry, and chooses the DA200 series high-performance servo drive with advanced algorithm, to meet and exceed customer expectations. Through customized servo motor with high torque, makes the axial rigidity has significant improvement, still serve on touch, without any sense of vibration, the customer very pleased with INVT this effect. The DA200 series servo matching 23Bit (8388608PPR) is used in INVT, which can meet the application requirements of high precision positioning control and low speed operation. The result of the actual debugging is the instruction time 11.875 ms, the rotary axis servo positioning completes 13ms, the whole time is less than 2ms, the retention pulse is 0 pulse, better than the setting time of the customer's requirement 5ms, the position error two pulse.

Time is money, which is more important in the LED industry. Make full use of INVT DA200 servo superior response performance, pull high motor's bandwidth, make the whole operation of the equipment achieve the optimal state.

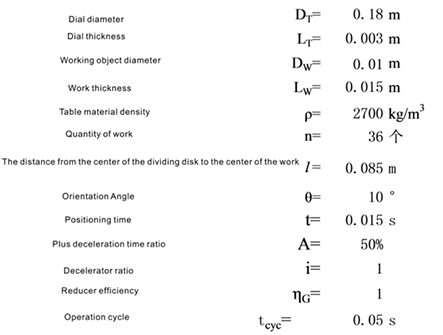

2.2 Dielectric motor design

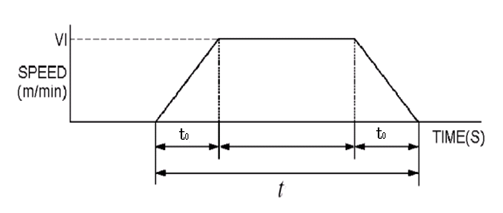

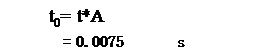

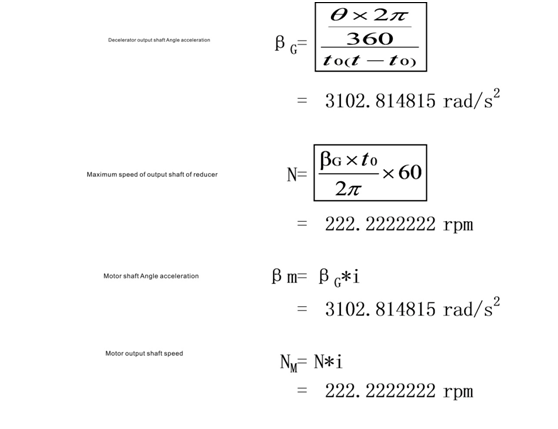

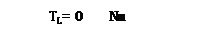

1) decide to add deceleration time

Add deceleration time to the 50% efficiency of locating time:

2) motor speed

3) calculate load torque

Because of the minimal friction load, it is ignored:

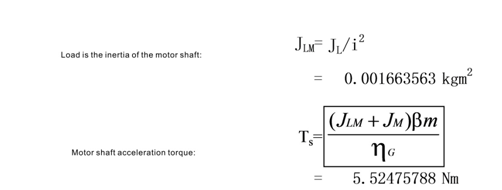

4) calculate the acceleration torque of motor shaft (overcome inertia)

5) acceleration torque

6) torque must be torque

* Safety factor S=1

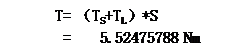

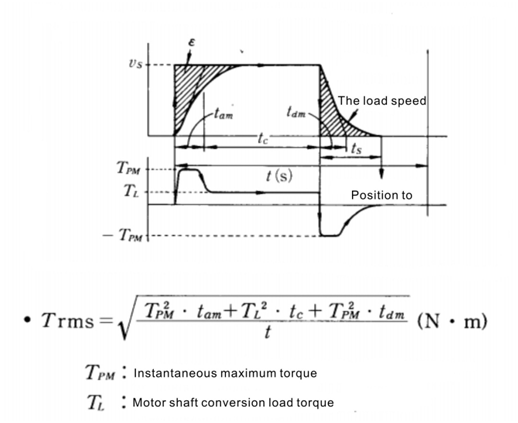

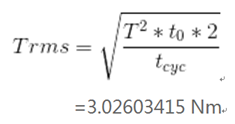

7) rated torque

It is assumed that the process only has a deceleration phase and no uniform velocity. The formula is simplified to:

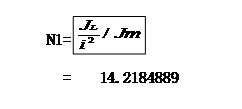

8) load and motor inertia ratio

According to the above data customized special motor, in practice application also proved to be consistent with the calculation data.

3.Process flow

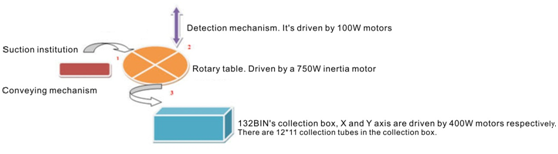

LED light machine is mainly used in LED products detection and spectral color consistency, spectrum analyzer is equipped with a sophisticated, high intelligence, can automatically detect the unqualified products and waste will blow in box, and the system architecture is the circular plate with parallel vibration track vibration is responsible for the feeding, with suction nozzle will be LED to the rotary table, through the test stand volume metering electrical characteristics, the system will according to the test results of test equipment, through institution will be LED to too much of the blanking box.

FIG. 1 process flow chart

Feed mechanism to the fixed position to absorb the material the material to the potter's wheel 1 - turntable of a rotary Angle of the material to the workstation 2 - examination organization down work to collect relevant data - dial again after the testing of material sent to the station 3 - high pressure air gun blow the material into the boxes (boxes will be according to the test results, determine the position of the good collection tube in advance).

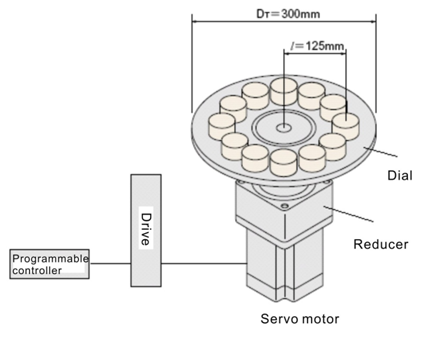

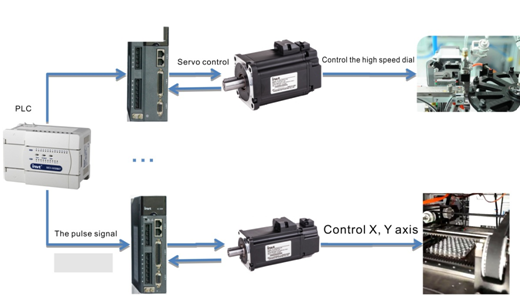

FIG. 2 schematic diagram of equipment electric control configuration

FIG. 3 schematic diagram of equipment

Product parameters of the spectrometer

Know the technical parameters of the product in detail

Electrical test parameters

| No. | Measurement of electrical parameters | Test condition range | Test resolution |

| 1 | Discharge voltage POL | 0.001—500MA | 1mV |

| 2 | Forward voltage VF | 0.001—500MA | 1mV |

| 3 | Inverse current IR | 0.1V—20V | 0.1µA |

| 4 | Forward current IF | 0.1V—20V | 0.01 mA |

| 5 | Reverse voltage VR | 1-1000µA | 1MV |

Optical test parameter

| No. | Photoelectric test parameter | Test range | Repeatability test accuracy |

| 1 | Chromaticity coordinates XYZ | CIE1931&1964XYZ Visible range standard | ±0.001 |

| 2 | The main waveλd | 380nm-780nm | ±0.3mm |

| 3 | The peak wavelengthλp | 350nm-1000nm Can be configured according to customer requirements | ±0.8mm |

| 4 | Half wave widthλd | 350nm-1000nm Can be configured according to customer requirements | ±0.5mm |

| 5 | Color purity PUR | PUR | ±0.01 |

| 6 | The light intensity MCD | Visible/infrared light | ±5% |

| 7 | Correlated color temperature CCT(µrd) | 1000K—40000K | ±0.8% |

| 8 | Luminous flux ФV(Unit MLM) | According to the attenuation rate And the integral sphere | ±0.6% |

Main technical parameters

| The spectrophotometer system | Independent research and development, independent intellectual property rights |

| Classification ability | 132BIN or 264BIN |

| Maximum capacity | 40Kh |

| Back to the BIN rate | ≧95% |

| Test station number | 1 stand |

| Power supply | AC220V 50Hz 10A |

| Air pressure | 0.45-0.50Mpa |

| The vacuum source | Built-in vacuum pump |

| Power | ≦2.30Kw |

| External dimension | 1220mm x 770mm x 1860mm |

| Weight | 460Kg |

* The customer hopes to increase the maximum capacity to 65K/h.

4. Servo parameter adjustment

A. Use of stiffer and speed feed forward

1) Adjust the inertia and observe R0.51 actual inertia value

2) Improve rigidity to about 21

3) Improve the speed gain. The speed gain is between 500 and 900 times.

4) Add feed forward to 56%

5) Use the filter trap wave

Effect: it is better, but it can be observed from the waveform that 13.3ms can be moved after the completion of the action, and the use of the high-speed camera to observe the completion of 14ms will still have a slight wobble.

B. expert debugging - use speed observer

1) first adjust the inertia, the inertia is better than the set, can observe R0.51 in real time to adjust.

2) then adjust the speed loop gain to the increase, adjust to the vibration, observe the torque fluctuation can get the vibration frequency, and use the trap filter to suppress. (more than 1KHz can deepen the depth to 0 and Q is 1)

3) when the torque is stable, open the velocity observer. Gradually increase the speed observer gain (depressed).

4) when the speed observer gain is improved, the speed loop gain can be greatly raised, which can be added up to 50Hz until it is depressed.

5) improve the speed gain, improve the position gain, and make the last few pulses close quickly. The general velocity gain increases after the increase of the position in the range of 1.5 times.

5 Project summary

After using the speed observer:

- the gain is greatly improved, the response is fast, the whole time is only 2ms;

- the noise is reduced and the sound becomes clear and crisp;

- the load rate becomes lower and the motor temperature drops significantly.

- maximum speed of 72K (higher) per hour, exceeding its mechanical speed limit;

After more than two months of testing, the equipment is in good condition, the product yield is high, and the work efficiency of the equipment is increased by 80% (from 40K to 72K). The INVT DA200 has won high recognition from customers with its high precision, high response and high value.

As LED the market demand, further more, the LED will be increased demand for manufacturing equipment, the successful application of INVT servo on the spectral, lay solid foundation for the INVT more products to enter the industry.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.