1. Project background

Under the background of global green transformation and China's vigorous implementation of various policies such as "double new" (promoting large-scale equipment renewal and replacement of old consumer goods with new ones), large domestic steel companies are also actively seeking the path of "domestic substitution" for key equipment.

The coke quenching car is a supporting equipment for large coke ovens. One of its main tasks is to transport and load the high-temperature coke produced by the coke oven. In order to achieve the smooth transfer of coke from the coke oven to the coke quenching car, during the docking process, an automated control system is generally used to perform precise position control to achieve accurate docking between the coke oven and the coke quenching car.

2. Customer requirements

In the coking plant of a large domestic steel company, the quenching car transmission system is seamlessly replaced by "domestication" to solve the problems of high failure rate of previous products and lack of spare parts.

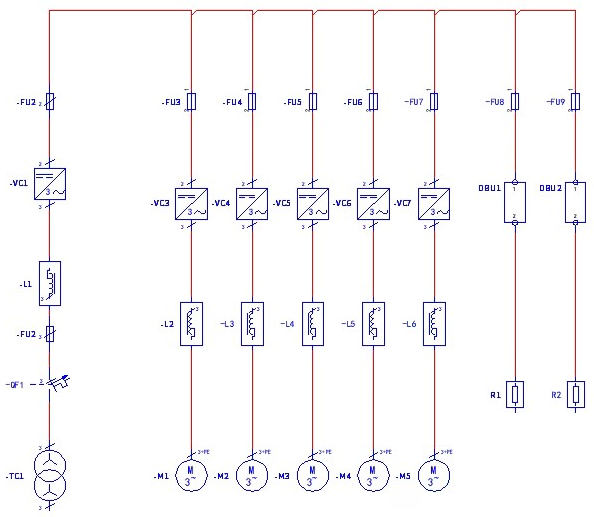

The coke quenching car consists of a drive car and a non-drive car, and the car is driven by 8pcs 55kW, 690V AC motors.

Requirements:

* Equipment replacement, use of existing space;

* The coke quenching car requires 8 motors to run synchronously to ensure safe and stable operation of the workshop;

* Low-frequency and high-torque output enables the coke quenching car to run at low speed and full load;

* High dynamic response to achieve precise positioning.

3. INVT solution

According to the actual needs of customers, INVT customized a transformation plan for customers, using INVT GD800 series engineering transmission VFD to replace the original transmission cabinet solution.

GD800 communicates with the host computer S7-400 control system via Profibus-DP, enabling the GD800 to seamlessly replace the original VFD.

In addition, GD800 has the following features:

1 High reliability, with long-life component selection and various protection guarantees, capable of withstanding harsh application scenarios.

2. Low-speed, high-precision control and high dynamic response, strong overload capacity, ensure process consistency.

3. The modular design takes up little space, shortens delivery time, and facilitates subsequent maintenance for users.

4. Customer value

By adopting INVT's alternative solution, the customer gained the following benefits:

1. Cost reduction: The transmission system of the coke quenching car is localized, reducing the cost by more than 40-50%;

2. Improved stability: The solution has good compatibility and meets the requirements of large vehicle walking synchronization and low-speed torque starting;

3. Timely maintenance response: INVT technical service team responds to customer needs 24/7.

5. Summary

The successful application of INVT GD800 series coke quenching car represents another success of INVT transmission products in the localization substitution of the steel industry.

INVT provides excellent transmission solutions for the entire process in the steel industry's mining, coking, iron-smelting, iron-making, steel-making, rolling, processing lines and other application scenarios, and supports the localization of transmission systems through continuous investment of resources. By reducing production costs and improving production efficiency, it provides better-quality transmission products and helps move forward on the path of domestic substitution.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.