1. Project background

With the continuous development and progress of science and technology, machine tool automation technology is widely used in the manufacturing process, which has a major role in promoting the technological innovation of the CNC machine tool industry,but the high-end CNC machine tools on the market are almost monopolized by Europe, America, Japan and South Korea from the system to the unit, therefore, our country is also constantly adapting to the situation and catering to the market, launching low-cost and efficient CNC automation equipment.

Figure 1: Field application diagram

2. Pain points of the project

In a CNC company in Jinan, the customer put forward more urgent needs for the CNC drilling center machine tool equipment:

● Realize the tapping function while maintaining the positioning accuracy;

● Reduce the manufacturing cost;

● Overcome market changes and deliver on time;

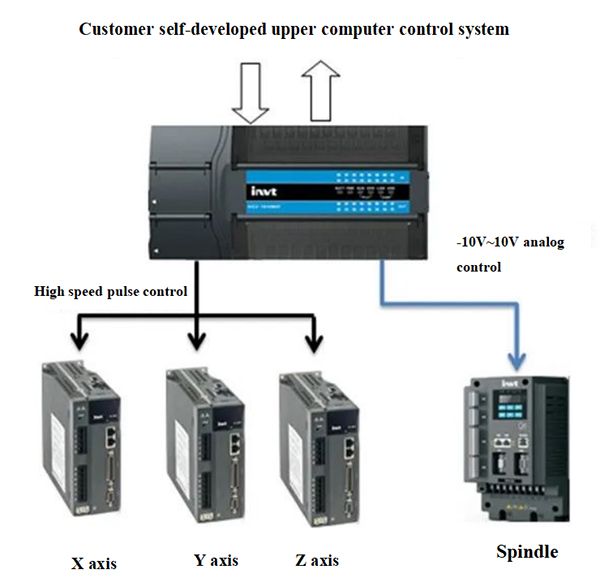

3. INVT solution

DSV200 product advantages:

● Smooth speed:DSV200 is equipped with the AB phase encoder inside the

motor and the Z phase position after the external reduction ratio, so as to

achieve a stable spindle speed.

● Precise positioning:With high-speed position function and advanced

control concept.

● Tapping function:DSV200 software internally supports two tapping

methods of analog quantity and high-speed pulse, using PLC and matching

with elastic drilling and tapping chuck to realize the tapping function.

In order to actively respond to customer needs, based on the technical

characteristics of DSV200, INVT proposes a complete system solution for

drilling and tapping centers:Using PLC to replace the CNC system, combined

with feed servo + asynchronous spindle servo (frequency conversion), this

solution has the advantages of low cost, high efficiency, and advanced

functions.

4. Customer value

● Operational threshold: greatly reduced

Adopt PLC control system: control spindle forward and reverse, precise positioning, tapping function, etc.

● Production cost: drop by 1/3

Adopt PLC control system: the cost is reduced by one-third compared with professional numerical control system.

● Production lead time: stable

Due to recent market changes, the procurement cycle of CNC systems has become longer, and even out of stock, while the general PLC procurement cycle does not have this problem in the market.

INVT's complete solution for drilling and tapping center,under the background of unbalanced development of the domestic CNC machine tool industry, breaking through the traditional industry thinking, breaking the routine, with a new way of thinking,combining professional CNC machine tools with ordinary PLC control can not only achieve the functions of CNC machine tools but also reduce industry costs.Another technological breakthrough that promoted the diversification of machine tool products,Realized the transition from "big investment" to "doing big things with small money".

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.