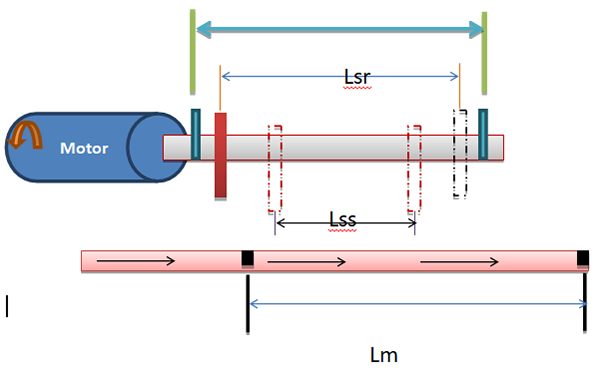

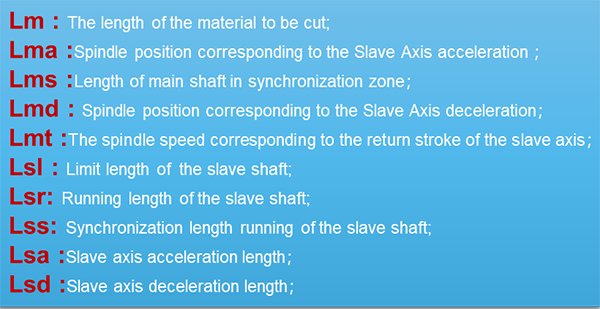

Abstract: As for the electronic cam, we have talked about the flying shear, Chase saw is also a reflection of the electronic cam, the biggest difference between them is that flying shear is always in one direction, while chase saw is a roundtrip movement. In the present industrial production, the fixed-length cutting of various materials is an important step in the whole process, and with the improvement of automatic technology and the maturity of movement control system, the fixed-length cutting device has developed from the traditional stop draw to chase saw, which has greatly improved the working efficiency, meanwhile, the synchronous cutting performance can also reduce the motor power and better control the cost. Chase saw characteristics: feeding shaft maintains uniform one-way feed, "turret" servo motor does reciprocating motion in the cutting table, which reaches synchronization to the feed shaft speed in the synchronization area, and completes the cutting action, then back to the original point, Tracking synchronous cutting again, cutting method can be pneumatic control or the chain saw control, which is called chase saw.

Keywords: AX PLC, Ether CAT, E-CAM, DA200, Synchronization

1. Introduction

MACHINE PROCEDURE:

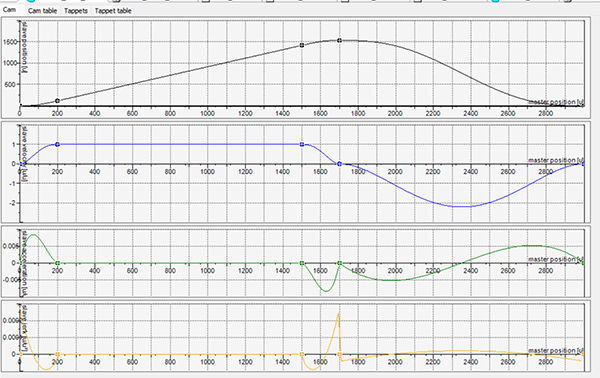

A. Standby state: at the beginning of a cycle, if the feed length has not yet reached the specified cutting length, that is, standby mode. AX PLC adopts pre-set amount detection method to detect the length and real-time speed of the input material, if the length reaches the pre-set amount, the servo motor running enters into the ramp up to tracking state.

B. Ramp up to tracking state: feeding continued, at the same time of detecting input material length and speed, the PLC commands the servo motor to accelerate to the synchronized speed to feed speed in accordance with the S curve. At the moment of entering the synchronization speed, the dynamic relative position of the saw and material has been set to complete, and then enter into the synchronization area.

C. Synchronization state: Once enter into the synchronized state, the PLC immediately sends out synchronization signal to the institution outside responsible for cutting or sawing, requiring the implementation of cut action. At the same time the PLC continues to detect the length and speed of feed, to keep the same relative position between the saw and material at any time, so as to ensure the smoothness of the cutting section, when the cut is completed, the cutting device exits and issues cut complete signal, the servo is no longer continue to maintain synchronization after receiving the signal and immediately enters into deceleration state.

D. Deceleration state: The PLC commands servo motor to immediately enter the deceleration zone from the sync zone and decelerate to 0 according to the S curve, meanwhile keep detecting and accumulating the feed length and immediately entering the return state.

E. Return Status: During the return process, the PLC continuously monitors the feed length feedbacked by the actual position. The system automatically enters the standby state after the return process is completed and waits for the start of next cycle.

2. Project information and Solution

2.1 Project information

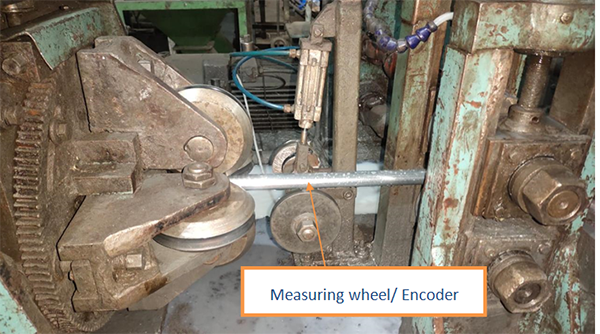

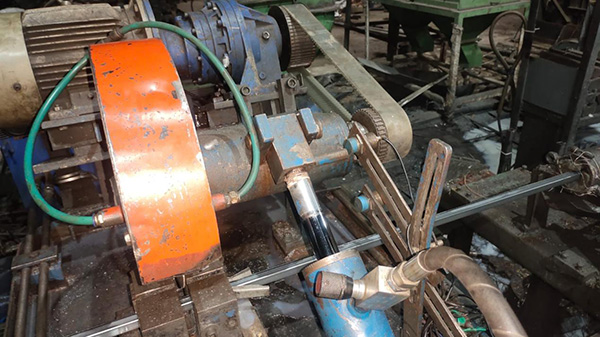

Site information: steel/Pipe manufacturing company

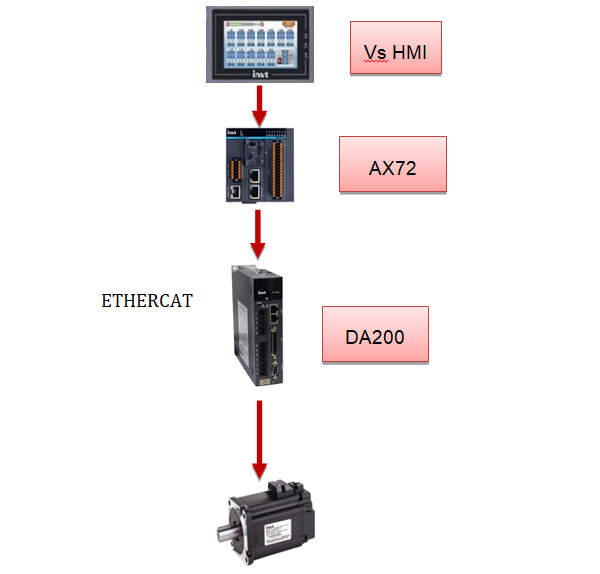

2.2 INVT solution

Product | Model no. | Qty | Application |

PLC | AX72C-1608N | 1 | CONTROLLER |

EXTENSION | AX-EM-0016P | 1 | CONTROLLER |

HMI | VS070QE | 1 | CONTROLLER |

SERVO MOTOR | SV-MM18-5R5B-4-1A0-1000 | 1 | CHASING SHEAR |

SERVO DRIVE | SV-DA200-5R5-4-N0 | 1 | MAIN MOTOR |

2.3 System Configuration

2.4 System commissioning

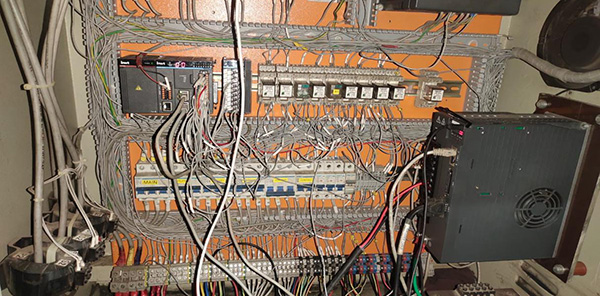

Control panels

3. Advantages and benefits

* High speed 8 pipes cut per minute of 6000mm with 0.20mm accuracy.

* Faster then usual cut to length as for cutting machine doesn’t stop

* Less maintenance due to servo motor.

* 50 numbers of recipe for cutting the pipe of different length and different diameter.

4. Conclusion

Visible, the fast response characteristics of AX PLC built-in high-speed computing performance and servo system can easily achieve the chase saw function, AX PLC has obvious advantages in the movement accuracy, output flexibility, speed and acceleration control. Chase saw suits for: the centrifugal knife fixed-length cutting machine in the back end of cosmetics or toothpaste hoses extrusion machine, the fixed length sawing machine on the back end of high-frequency welded pipe production line, steel plate fixed length cross cutting machine and filling and loading machine on the back end of PVC pipe. INVT has given Cost effective solution in chasing shear application in india and machine is successfully running with customer satisfaction.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.