Air-jet covered yarn (known as ACY) making involves simultaneously stretching the outer fiber filament and spandex filament through a certain type of nozzle and forming a rhythmic network of points through regular high-pressure air spraying. The ACY has a smooth hand feel, and this process is environmentally friendly and energy saving. It can also effectively handle some special fiber materials. Based on these characteristics, ACYs are widely used in the fields of advanced textiles and new materials.

1. Urgent renovation needs

A textile production enterprise did not fully meet the processing demand using the original ACY control and drive system; in order to improve the market competitiveness, the customer decided to carry out system renovation and upgrade and seek more reliable solutions to reduce yarn breaking phenomenon and improve production efficiency.

2. INVT solution

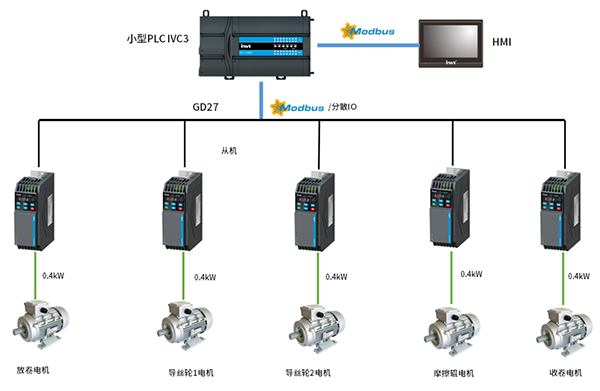

In order to meet customer demand, INVT proposed to upgrade the system with the brand new GD27 series VFD. The VFD controls the frequency output through RS485 communication. Up to 30 VFDs can fast respond to the equipment in synchronous mode. Compared to conventional mechanical drive methods, INVT VFDs can effectively help to reduce the yarn break chance and increase productivity.

* Low-frequency torque output is large, driving synchronous motors.

* Speed output during ACC or DEC is stable.

* Excellent communication performance, multiple VFD communication, and wonderful anti-interference performance.

* Fast output with a maximum running frequency of 200Hz, with the yarn drafting speed up to 1200M/min.

3. Customer benefits

INVT GD27 series VFD effectively solves the problems in traditional ACY machines, resulting in improved production schedule and increased efficiency.

* Fast output: Yarn drafting speed up to 1200M/min, production efficiency improved by 20%

* Yarn breaking chance reduced: Up to 30 VFDs can fast respond to the same equipment in synchronous mode.

* Cabinet space saving; GD27 is more compact, with the width reduced by 20%

In the successful application of INVT GD27 series VFDs in the ACY machines, the problems in traditional ACY machines are solved by providing stable speed output, strong communication performance, and fast output frequency.

The current Chinese textile industry has entered a new development period. Based on continuous technological innovation, INVT provides a variety of system solutions from textile to weaving to clothing for the textile industry, effectively helping customers to improve market competitiveness.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.