The global printed circuit board (PCB) industry is a fast-growing high-tech industry that plays a vital role in the manufacture of modern electronic equipment. High speed blowers play an important role in the production of circuit boards. High speed blowers use high velocity airflow to blow away tiny dust and water droplets from circuit boards, making them easier to dry and improving efficiency in the next process.

If the process effect does not meet the standards, the board moisture is not dried, the produced board impurities may be too much, or the adhesion is not secure in automatic welding, the rate of failed products increases. To ensure the stability and reliability of product quality, a circuit board manufacturer in Zhejiang is looking for an efficient, energy-saving blower system solution.

INVT solution

According to the onsite application of the circuit board manufacturer, INVT provides a high speed blower application solution that is based on INVT GD27 series Smart VFD, with the following product advantages: adopting the constant current mode and using current control to increase the rotation speed, so as to achieve stable flow and equipment running with low power consumption but in high performance.

GD27 features:

* New generation motor control platform: Capable to drive asynchronous motors and permanent magnet synchronous motors, and supporting SVC and V/F control modes

* Supported motor cable length: Up to 150 meters, without additional output reactors

* Built-in safety function: Safety torque off (STO)

* High environmental adaptability: Running reliably at full load with the ambient temperature up to 50℃

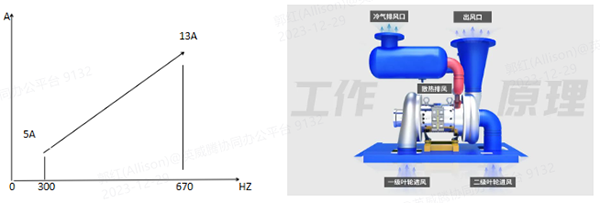

Constant current mode graph:

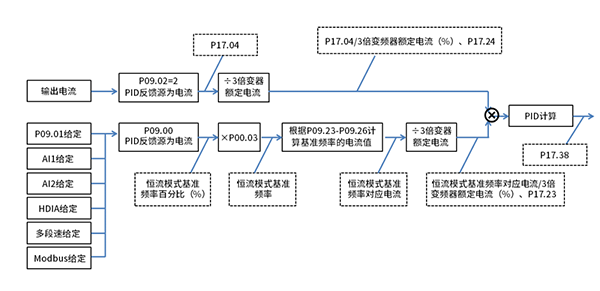

Constant current mode control block diagram:

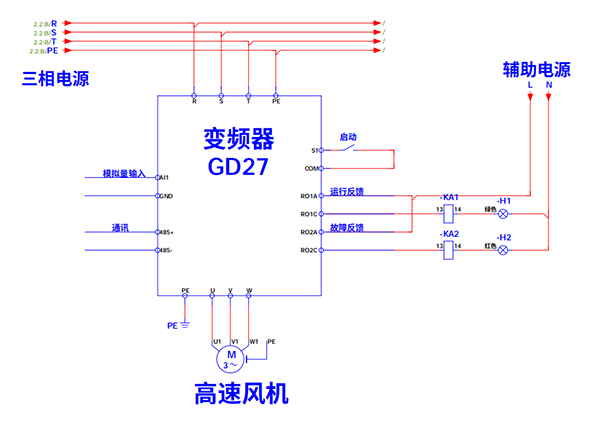

Overall control diagram:

Customer benefits

The board manufacturer benefits from the solution that is based on INVT GD27 ac drive:

* Energy saving: High speed blowers not only meet the technique process requirements, but also achieve energy saving.

* High efficiency: The operations of moisture removal and drying are more stable. The VFD usually runs at a high efficiency frequency of above 500Hz.

* Quality improvement: High speed blowers provide stable wind power, facilitating circuit board quality and improving product compliance.

* Life extension: Thanks to the reasonable design, the high speed blowers have long service life, reducing the frequency of equipment replacement in the circuit board plant, reduce equipment investment costs

* Green: High speed blowers generate low noise and do not produce harmful substances, meeting environmental protection requirements, compliant to the green development policy.

With the rapid development of smart phones, electric vehicles, the Internet of Things, the demand for circuit boards is growing. The circuit board processing plant is facing the opportunity of technological upgrading and innovation. In addition to high speed blowers, INVT has a wide range of applications in other equipment in the industry. INVT helps the circuit board plant to improve competitiveness and expand market share by means of technological innovation, quality improvement, and service upgrading.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.