Abstract: Automatic winding machine is a new type of machine developed in recent years, in order to adapt to the requirements of high efficiency, high output, automatic machines are generally used in the design of multi-head linkage, most of the China manufacturers use programmable controllers as the core of the equipment control, with the manipulator, pneumatic control elements and implementation of the annex to complete the automatic line, automatic winding, automatic wire, automatic shearing, automatic loading and unloading of the skeleton and other functions, the production efficiency is very high, greatly reducing the dependence on manual labor, an operator can look after several such equipment at the same time, the production quality is more stable, very suitable for high yield requirements of processing occasions. The production efficiency of this model is very high, greatly reducing the dependence on labor, an operator can look after several sets of equipment at the same time, the production quality is more stable, and is very suitable for processing occasions with high output requirements. The case mainly introduces the transformation of a German-made choke coil winding machine, the whole set of solutions using INVT including AX72 controller, VS-Q touch screen and DA200 servo system.

Keywords: Winding machine DA200 AX72

1. Preface

The machine is used to wind large choke coils for industrial use. The machine has a maximum choke coil size of 1 400*1 400 mm and a maximum permissible choke coil weight of 1 000 kg. The machine is controlled by a PLC via EtherCAT bus with servo-driven motors to achieve smooth running, low noise and high efficiency. This program adopts INVT AX72 PLC, DA200 drive and VS touch screen, which has the advantages of fast action response speed, high product production efficiency and convenient touch screen interaction.

2. The main features of the winding machine

System components:

1, Removable bracket - ball screw + SV-MM13-1R0E-2-9A0

Multi-turn absolute encoder with battery backup - no homing required after power-up

Automatic positioning of wires on coils using MC_GEAR (spindle as MASTER WINDER)

2, Sliding bracket - ball screw + SV-MM13-1R0E-2-9A4

Multi-turn absolute encoder with battery backup - no homing required after power-up

Speed control with torque limitation for fixing chokes between winders

3, Main Winding Machine - SV-MM18-7R5B-9A4 + Spiral Bevel Gearbox

Speed control with MC_VELOCITY

4, Slave winder - SV-MM18-7R5B-9A4 + spiral bevel gearbox

Synchronized movement (winding) with master winder using MC_GEAR

5, Wire bending (2 motors) - ball screw + IMS20A-06M40B30C-2-P9

Multi-turn absolute encoder with battery backup - no homing required after start-up

Bending of wires according to recipes

Absolute positioning with MC_MOVEABSOLUTE

3. System control realization

According to the control requirements, motor response speed, work efficiency. Select AX72 controller EtherCAT bus control servo way to control the operation of the device, in order to facilitate customer site installation and commissioning. Because Modebus TCP communication has the advantage of high-speed communication, easy to wire, using the VS-Q touch screen with TCP network port.

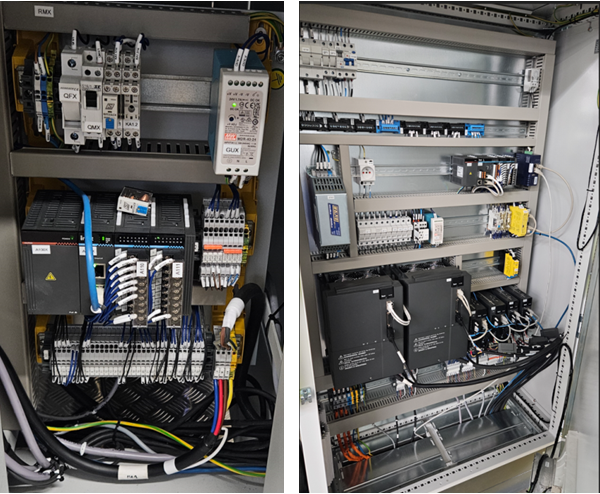

Electrical cabinet

4. Functional advantages

4.1 Bus control response speed

This program adopts EtherCAT bus control, compared with the traditional way to greatly improve the response speed, simplify the wiring convenient for customers, easy maintenance.

4.2 Servo 23bit multi-turn absolute encoder

No homing action of the drive - continues to work after power failure (the next day). Choke coil production (single piece) can last more days.

4.3 Integration of 100 recipes in the controller

AX72 controller integrates 100 recipes to meet different needs of product production.

5. End

The customer decided to retrofit two old winding machines (made in Germany) with our complete solution, so the task was successfully completed. This project also opened the way for us to offer solutions for other types of machines.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.