1. Background

According to market research reports, the production and sales of wire ropes have grown steadily in recent years. In 2023, the global wire rope sling market sales reached 3.9 billion yuan, and it is expected to reach 6.2 billion yuan in 2030. Wire rope slings are widely used in industrial and agricultural applications such as oil drilling, power transmission, ship lifting and unloading, and elevator lifting. The huge market demand has prompted more wire rope companies to increase market investment and pursue higher quality and high efficiency twisting machine equipment.

2. Customer Needs

A steel cable company in Jiangsu proposed technical requirements for the twisting of steel wire ropes. The twist direction, twist pitch, strand diameter, core diameter, diameter of the strands, tensile strength, toughness, coating quality, length, etc. of the strands must meet the specified requirements. The hole diameter of the wire pressing shoe must be consistent with the strand diameter, and the inner surface must be smooth to ensure that the twisted strand structure is tight. when twisting strands with line contact and point-line contact, the installation position of the spool wheel must be correct to prevent the steel wire from crossing at the twisting cone.the strands must be arranged flat in the take-up wheel, the strands must not be loose, and the accidents of running heads and length and short meters must be prevented.

3. INVT Solution

Based on customer needs, INVT launched the GD600 series high-performance multi-drive VFD solution, which has the advantages of high efficiency and high quality:

1. The winding length or winding diameter can be set, and there are early warning and full roll alarm prompt functions to effectively ensure more stable winding and avoid wire breakage.

2. The tension is balanced and consistent, the tension accuracy is high, the effect is better, and the twist distance control is more precise.

3. Use GD600 multi-transmission products and book-style installation to save 30% of the control cabinet space.

4. The system has a simple structure, easy debugging, strong operability and high stability.

5. When decelerating, the bus voltage can be kept consistent, the speed reduction synchronization can be ensured, and the wire surface tension is constant.

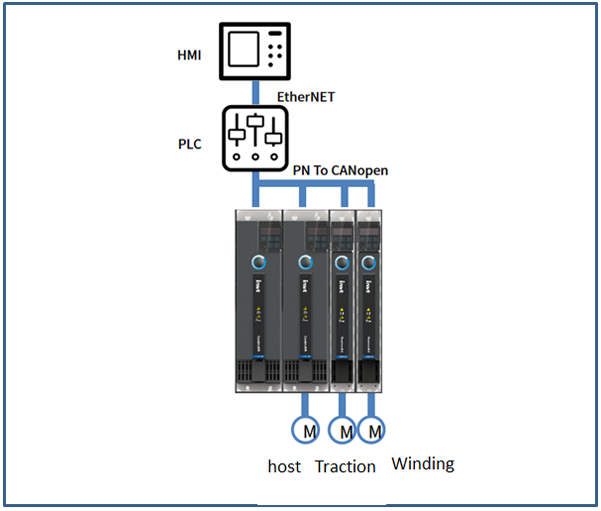

Solution topology diagram

4. Customer Benefits

* The overall system solution and bus control can make the overall control of the equipment more efficient and precise .

* The shared DC bus solution realizes internal energy flow, improves system power efficiency, and achieves 30% energy saving.

* GD600 multi-transmission design greatly saves electrical cabinet components, reduces failure points, and saves maintenance costs .

* Automatic parking protection for wire breakage and automatic brake protection for power failure.

5. Summary

In this stranding machine frequency conversion renovation project, INVT GD600 high-performance multi-drive inverter solution fully met the on-site use requirements, and its excellent product performance was highly recognized by customers.

At present, strand twisting machine equipment has entered a new stage. While facing the changes in market demand, INVT will continue to strengthen technological innovation, improve product quality, and contribute to the sustainable development of the industry.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.