Abstracts: The working principle of the shearing machine depends mainly on the relative motion between the blades and the fixed blades. When the plate passes through the gap between the upper and lower blades, the blades shear the plate, thus realizing the cutting of the plate. A hydraulic system is usually used to drive the movement of the blades, which is characterized by high efficiency and precision. Daily processing needs to cut the material in multiple sections, due to the large width of the material, the loading system needs to synchronize the feeding of multiple axes and ensure a certain degree of feed accuracy.

Customer Requirements

With the continuous innovation of automation technology, the customer's requirements for the shearing machine are gradually strict, the current equipment has the following problems, which need to be optimized and upgraded:

1, Synchronization of loading is not enough, need secondary fine-tuning, do not have two-axis, three-axis synchronization selection function;

2, The start-up needs to return to zero, which affects the efficiency, and the position needs to have a memory function and automatically locate to the processing position;

3, The order cutting planning is not intelligent enough, and the specifications need to be artificially determined;

INVT Solution

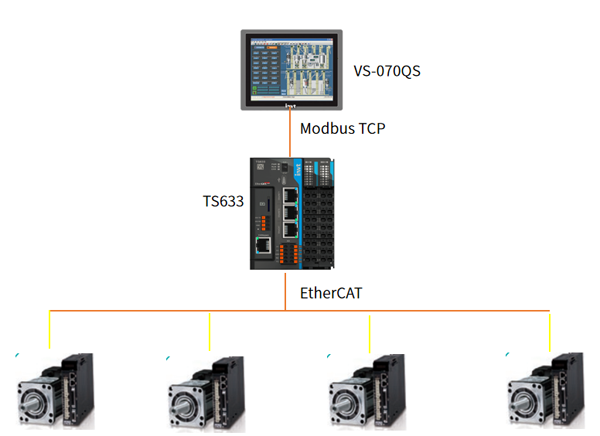

In order to meet customer needs, INVT has launched a new solution: HMI+TS633 series PLC+DA180A series servo drive. The scheme adopts TS633+DA180A control technology to ensure the stable and reliable operation of the shearing machine.

The TS633 PLC, with excellent data processing capabilities and efficient data transmission speed, provides users with a full range of drive and control solutions. TS600 integrates four types of automatic control of sequence, process, information and operation control in the same system, and the real-time control and complex computing functions are completed by high-reliability software and hardware real-time systems.

DA180A N-type servo, bus communication with the control system, synchronization period of 1ms, fast communication speed, strong anti-interference ability. The servo motor uses a 17-bit absolute encoder, which has a fast response and high positioning accuracy, and can maintain the current position after power failure. The DA180A has a built-in dynamic braking function, which can stop the operation immediately when it alarms during high-speed operation, and protect the equipment from impact damage.

Solution Value

Compared with the traditional shearing machine, it has the following characteristics:

1, Higher precision: Using advanced control system and transmission system, PLC axis group function realizes synchronous feeding and feeding, which can achieve high-precision shearing with an error of ±0.5mm.

2, Higher degree of automation: the use of numerical control system for control, can achieve automatic shearing, reduce manual intervention, and improve production efficiency.

3, Wider range of application: It can be applied to a variety of plates of different materials and thicknesses, such as metal, plastic, glass, etc., which can meet the needs of different industries and different users.

4, As long as the length of the raw material and the cutting size are entered, it will be automatically positioned to the cutting position, which is convenient and fast, and the counting function of the quantity is helpful for customers to count and manage.

Conclusion

Through continuous optimization and innovation technology, INVT has made outstanding achievements in compressor, lifting, printing package, lithium battery and other automated manufacturing equipment, and has been trusted and recognized by many enterprises. In the future, INVT will continue to invest in R&D to serve users with high-quality products and solutions to save energy and increase efficiency.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.