Abstract: A machine will used in the wire cut chambers to pick and place on the pallets. First the soil will move via conveyor and it will drop in to the crusher machine to convert the hard soil in to the powder format. Then this powder type soil will move with another conveyor and it will drop in to the extruder machine. This extruder will compress the soil powders and will convert in to a rectangular shape bar. Then the bar will move to the rotary conveyor and one encoder will coupled in the conveyor. Based on the encoder feedback we can cut the continuous lengthy bricks in to the required length. Then the required bar will cut in to the brick pieces. Then the final brick piece will pick by the help of the stacker machine and then it will place on the pallet.

Keywords: AX PLC, HE-HMI, DA200 servos, Pulse based absolute movement.

I. Introduction

MACHINE PROCEDURE:-

A. Hard soil to powder: First the raw soil will moved on the conveyor and drop in to the crasher machine. This machine will convert the raw soil in to the powder format to make and bars and to remove the small stones.

B. Extruder unit: output of the crasher unit will move to another conveyor and it will drop in to the Extruder unit. This unit will compress the soil powder and convert in to the bar.

C. Encoder based roller moving conveyor: This is a roller type moving conveyor. It has an encoder and it will connected in to the PLC and it will read the pulses. Servo based cutter will attached in this roller conveyor. Bar length can define by the customer. Baes on the encoder feedback and define length servo cutter will cut the length bar in to small bars.

D. Wire cutting unit: This unit will cut the bricks in to the small bricks. Every cutting we can get 12 bricks on its outputs.

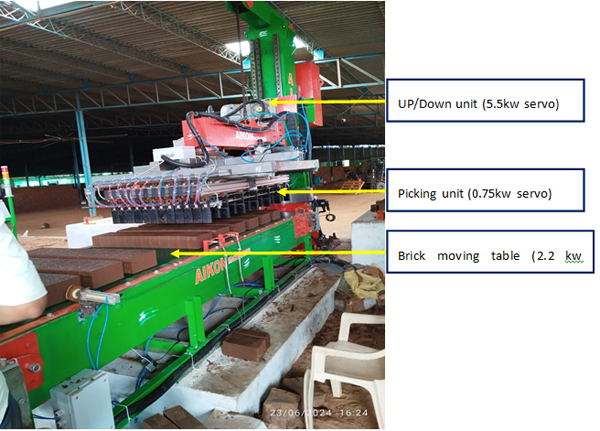

E. Table unit: This is an automatic table using to move the bricks to picking unit. For every move is 60mm distance for next brick gap.

F. UP/ Down and Picking unit: This unit have a gripper and splitter setup. 6 set of row bricks comes to the picking unit, unit will move to down and gripper will close. Then unit will move up.

G. Swing unit: swing unit will rotate right and left both direction. Overall rotation is 180deg. After rotate this unit down unit will down to pallet position and gripper will open to place the bricks on the pallet.

2. Project information and Solution

2.1 Project information

Site information: Wire cutting Chamber.

2.2 INVT solution

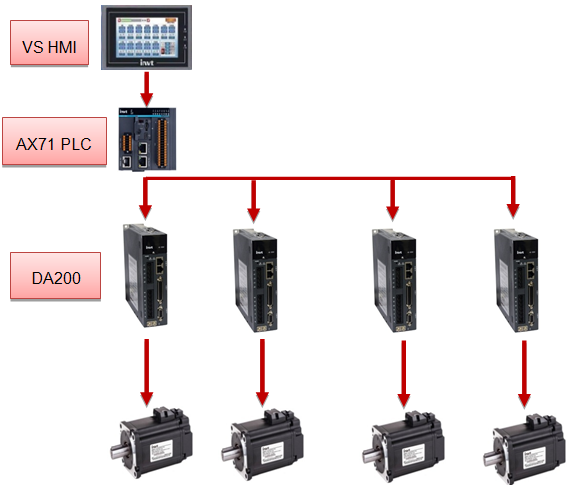

Product | Model no. | Qty | Application |

PLC | AX71C-1608N | 1 | CONTROLLER |

EXTENSION | AX-EM-0016P AX-EM-0016DP | 2 1 | CONTROLLER |

HMI | VS070HE | 1 | CONTROLLER |

SERVO MOTOR AND DRIVE | 2.2 KW 0.75KW 5.5KW | 2 1 1 | SWING AND TABLE PICKING UNIT UP/DOWN UNIT |

2.3 System Configuration:-

3. System commissioning

Control panels

4. Advantages and benefits.

• Easy to change the pick and place positions by using teaching mode.

• Maintain the same quality of bricks.

• Per day production is high compare with manual production.

• Production cost is low and man power will be very less.

• No.of rows per pallet and placing direction can change easily from HMI.

• Machine speed can set by customer.

5. Conclusion

Easy to operate the machine and can easy to control all functions by customer. Increase the production and reduce the manpower.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.