1. Project Background

Aluminum is the second most widely used metal in the world after steel, and is strong yet lightweight - making it ideal for applications in areas such as home electronics, construction and machinery.

From bauxite to aluminum is a long and highly technical process, and the mixer-kneader is one of the key equipments. The mixer-kneader system structure consists of a motor, a reducer, a mixing and kneading mechanism, a lubrication mechanism and so on. Since the electrolysis process is absolutely continuous, a 24/7 uninterrupted supply of carbon anodes is required. Therefore, the reliability and stability of the kneader drive is of paramount importance.

In the past, the relevant driving equipment is monopolized by foreign brands, but with the technology and service level of domestic brands continue to improve, the current localization alternative has become a major trend.

2. Customer Requirements

The customer originally used the international big brand VFD for a long time, and its VFD device life basically reached the limit, which had a great impact on the production schedule, so the customer wanted to optimize and update the related products.

Its requirements for new VFD products:

1. Completely replace the original product

2. High precision of speed control

3. High instantaneous torque, smooth power, low rate of change

For example, when there is a large piece of asphalt, the VFD must output a large torque in a short period of time will be a large piece of asphalt and other materials mixed evenly, in the output of a large torque at the same time but also requires a small change in the current and power, if more than the limit value of the DCS control system, the DCS system will be protected by the shutdown!

3. INVT Solutions

In the end, based on the supply cycle, price, maintenance, production stability and other comprehensive considerations, the customer decided to localize the original product replacement, and chose the INVT GD800 series engineering drive VFD.

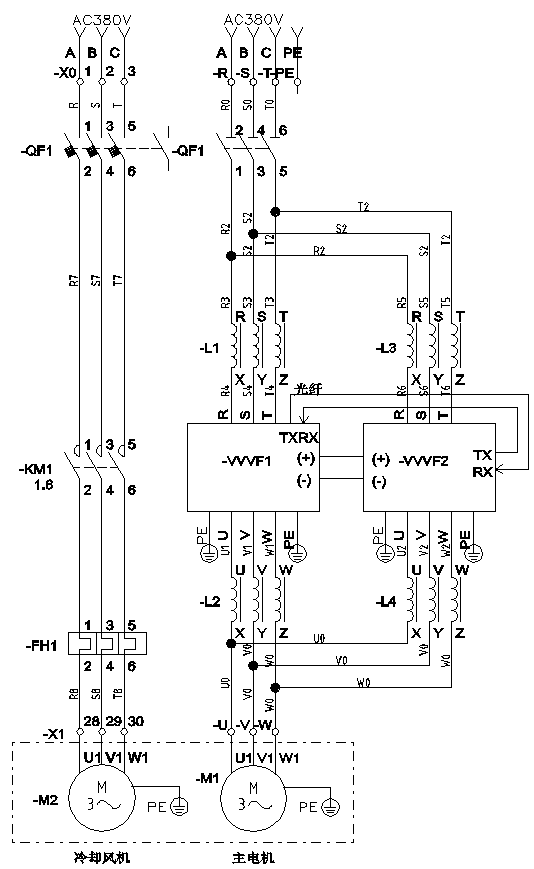

GD800 series engineering drive VFD has independent modular design of control unit; control unit and power unit adopts fiber optic communication, electrical isolation, strong EMC performance, and improve system reliability; control unit supports independent power supply from external power supply or DC bus power supply, which is convenient for the central control system to control the logic link; power unit is equipped with independent sub-control board, which can process the feedback of the bottom operation data in time to ensure that the control system can effectively monitor the bottom operation. Effective monitoring of the underlying operation, the motor side of the external fault can be quickly transmitted back to the control unit and other characteristics.

4. Program Value

Through this localization substitution, INVT's GD800 series products and solutions have achieved a perfect substitution for the international big brands.

1、In terms of reliability: reliable device selection, from the source of design to ensure product quality, the product average trouble-free time of up to 80,000 hours, high reliability, high stability, has been verified in a large number of sites, to ensure stable operation of the equipment, saving labor maintenance and equipment costs.

2、 In compatibility: support such as CANopen, Modbus, ControINet, DeviceNet, EtherNet/Ip, PROFIBUS, PROFINET and other mainstream communication protocols, PG card variety.

3、In terms of performance: start-up instantaneous output up to 1.5 times the full load operation, continuous 1.5 times the load over the load work up to 1 minute, in addition, support for asynchronous motors as well as synchronous motors open-loop vector and closed-loop vector control, control performance is superior.

4、In the after-sales maintenance:INVT 7 * 24 hours after-sales service system, and the country's service centers, can guarantee that 24 hours to arrive at the scene to solve the problem

5. Concluding Remarks

The application of INVT's GD800 series engineering drive VFD in the kneader of an aluminum company in Henan Province not only breaks the status quo of the kneader drive market being monopolized by foreign brands, but also establishes a benchmark performance among domestic brands.

In addition to kneaders, INVT has system solutions and achievements in all processes in the non-ferrous industry, helping global non-ferrous enterprises to improve energy-saving load equipment, reduce production and maintenance costs, improve automation, and enhance production efficiency.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.