1. Background

At present, for domestic steel enterprises, how to achieve healthy and sustainable development and further enhance market competitiveness is a major problem. Transmisson equipment as the largest load in the application volume of steel enterprises, VFDs play an important role.

In the past decades, metallurgical industry VFD are taken from imported brands, but with the adjustment and transformation of the steel industry, the promotion of localisation has become an important trend.

2. Slab deburring machine

Slab deburring machine is one of the important equipment in the production of continuous steel casting area, its function is to remove the burrs on the cutting surface of continuous steel casting slab. After the casting process, the slabs are separated into certain lengths by flame cutting. During this process, burrs are produced at the ends of the slab, and these burrs can be a major obstacle in the later process. To remove the burr, a hammer on the deburring machine roller that rotates at high speed is used to strike the burr. The deburring machine is mounted between the two rotating rollers of the roller conveyor.

Whether the deburring machine is normal and stable operation directly affects the cast billet hot feeding and rolling, and the stable operation of the transmission part of the casting machine production is critical.

3. Working principle

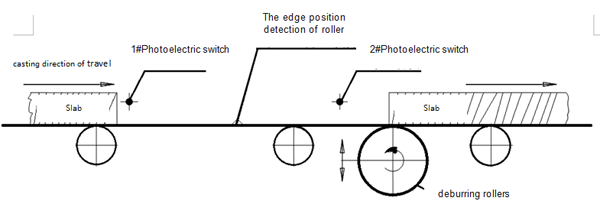

Slabs enter the deburring machine for the entire workflow: The head and tail of the slab are burred after flame cutting, and the transmission equipment of the deburring machine needs to quickly forward start to rise to high-frequency operation in the process of passing through the deburring equipment as a whole in the slab to remove the head burr, and then quickly stop the machine, and immediately reverse start to rise to high-frequency operation to remove the tail burr. Run this over and over again.

4. Client requirements

1 Depending on the length of the slabs produced, the VFD is required for fast braking and stopping, and frequent forward and reverse rotation. According to the shortest slab length deburring requirements, the VFD stops at high speed to zero speed in no more than 3 seconds, if the time exceeds, the deburring step at the end of the slab will not be completed. It will cause production accidents.

2. Deburring machine transmission load for dozens of knife hammer rotating to knocking burrs, is a large inertia load. High demands are placed on the control performance of large-inertia loads, as well as on the performance of high torque and high overload at high speeds.

3. Need to correctly match the original foreign VFD hardware wiring, correctly configure the terminal function. Matching PLC control system.

5. INVT solution

Based on the client's requirement, INVT introduced IPE300 to replace foreign VFDs.

At the same time, the INVT IPE300 perfectly matches the original VFD terminals wiring. Comb the terminal function configuration according to the parameter settings and the logic function diagram configuration of the overseas VFD.

Solution configuration:

No. | Name | Model | Brand | Quantities |

1 | VFD | IPE300-0075-4 | INVT | 1 |

2 | Input filter | FLT-P04150L-B | INVT | 1 |

3 | DP communication card | EC-TX503 | INVT | 1 |

4 | IO expansion card | EC-IO502-00 | INVT | 1 |

5 | Brake unit | DBU100H-110-4 | INVT | 1 |

6 | Brake Resistor | 6.8Ω/12000W | INVT | 1 |

6. Solution Advantage

Performance: Perfect realization of domestic substitution

1) The IPE300 inverter has a fast stop DC braking function, which can provide a stop brake current in a short time, so that the large inertia load can be stopped within 3s.

2) Reliable and stable for frequent forward and reverse applications, high frequency, high torque and high overload output performance.

3) With a flexible free programming module, the relevant functions can be correctly configured according to the internal free function blocks of the original VFD.

On cost: 30% cost reduction

1) The one-time input cost of the VFDs localization is saved by 30%, and the cost of spare parts in the later stage is saved by 50%, reducing the production cost.

2) INVT's branches and joint warranty centers around the world can quickly provide customers with high-quality pre-sales and after-sales technical service support.

In the future, in metallurgical production, INVT will continue to innovate and improve its product strength, and continue to move forward on the road of localization. Relying on its own technical advantages and experience accumulation, INVT VFD has been recognized by high-end customers, and has successfully replaced imported VFDs from Germany, Switzerland, France, the United States, Japan and other regions, which will help enterprises greatly reduce procurement costs.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.