Abstract:

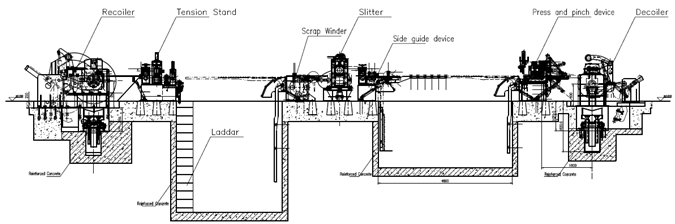

A slitter machine (commonly referred to as a slitter rewinder) is a special type of equipment used to convert / slit many different materials so they can be cut down into narrower rolls. Master rolls are often made to be as large as possible in order to be cost-effective. The rolls are converted / slit to the required widths, and are either rewound to the same diameter / length or reduced to smaller ones depending on their use and market served. These machines are available in a broad variety of configurations to help meet the individual needs of each industry that uses them.

Keywords: IVC1L PLC, Vs-Q HMI, GD200A, Slitting

1. Introduction

* Project information

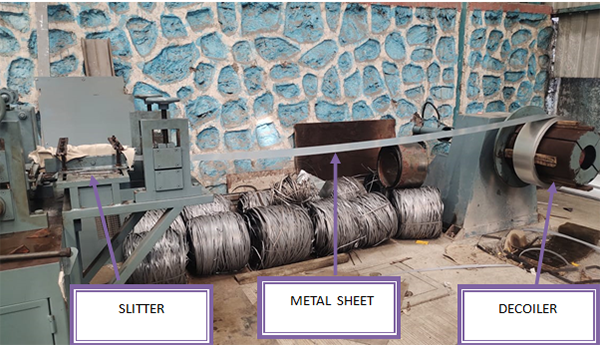

Site information: Metal/Steel line

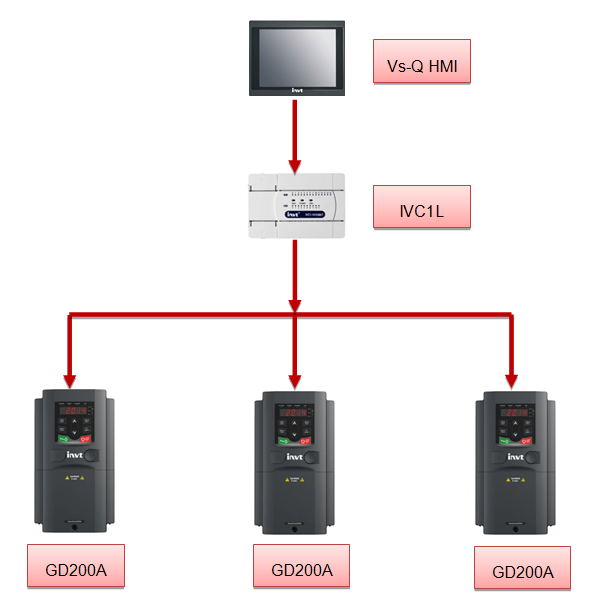

* INVT solution:

Product | Model no. | Qty | Application |

HMI | VS070QE | HMI | |

PLC | IVC1L-2416MAR | 1 | CONTROLLER |

GD200A-7R5G/11G-4 | 1 | DECOILLER | |

VFD | GD200A-7R5G/11G-4 | 1 | RECOILER |

VFD | GD200A-7R5G/11G-4 | 1 | SLITTER |

* System Configuration:

2. System commissioning

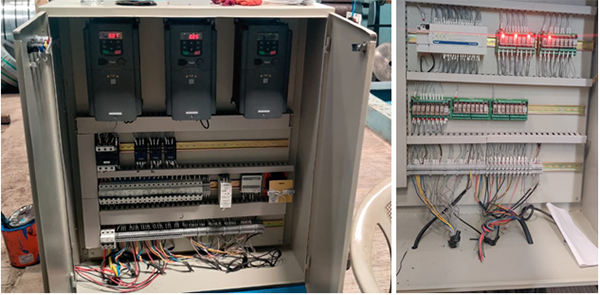

Control panels

3. Advantages and benefits

* Used for cutting narrow coil strips from main coils, our machinery comes in many widths and thickness and processes at speeds up to 300m/min

* Synchronization with the decoiler and recoiler and control the tension as well

* Screen display running parameter.

* Slitting length is 50mm to 200mm.

4. Conclusion

Automatic slitting machine application is successfully executed in steel plant and the Performance, accuracy and stability, all meet the process requirement. INVT has economical and effective solution as compare to delta and xinje for this kind of solution.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.