Abstract: With a group or several groups of parallel arrangement of yarn, on all the work by the feeding machine needle, into a circle to form a knitted fabric at the same time, this method if called the warp knitting fabric called warp knitting fabric. Complete the warp knitting machine is called the warp knitting machine.

Keyword: warp knitting machine, DA200

1.Introduction

Classification of warp knitting machine:

● Kurt type warp knitting machine

● Raschel warp knitting machine

Kurt type warp knitting machine

Raschel warp knitting machine

2.Project Analysis

The functions and characteristics of the warp knitting machine:

1.On the tricot warp knitting machine, fabric arise out of the knitting needle and needle bar is about 115 ° Angle between plane, fabric by sinker and pull roller pull together, make the coil to the formation of needle back, from the weaving area. This kind of warp knitting machine generally use crochet or groove needle, number and machine speed is higher, suitable for weaving organizational structure and design simpler warp-knitted fabric.

2.On the raschel machine, fabric direction and needle bar plane Angle between derivation above 140 °, fabric alone pull roll force. Raschel machine generally use tongue needle or groove, immediately and machine speed is low, suitable for weaving complicated organizational structure and design of warp knitted fabric.

3.Other special types of warp knitting machine, such as simplex crochet warp knitting machine is a kind of double needle bed warp knitting machine, used for weaving and close-grained glove cloth, garment fabric and industrial fabric. Milanese warp knitting machine using two groups of reverse mobile warp, used in weaving argyle. Other special USES of warp knitting machine, such as lace warp knitting machine machine, fishing nets, plush warp knitting machine, warp knitting machine, packet plate jacquard warp knitting machine and the whole picture of laying in warp knitting machine, sewing machine, etc

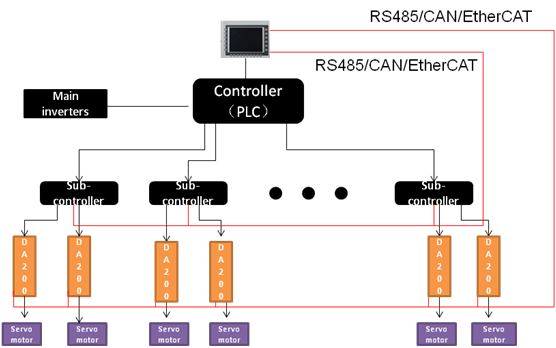

3.System Configuration

The warp knitting machine structure:

Warp knitting machine is mainly composed of weaving mechanism, stripping comb transversal, let-off mechanism, pull of mechanism and transmission mechanism.

4.Application and Advantage

The application of servo in warp knitting machine

5.Conclusion

After transverse warp knitting machine moving parts adopt servo, compact structure and more accurate stripping comb transversal, through almost unlimited, save and change the faceplate, chain block such as complicated work. Higher machine speed, reduce the weight of the moving parts, reduce the stripping comb to take up space, to comb yarn exercise can free design, computer time.

Reference

[1] Operation Manual SV-DA200 AC servo drives

INVT INDUSTRIAL TECHNOLOGY (SHANGHAI)CO., LTD.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.