Abstract:

This article mainly introduces the mature application of INVT DA200 series servo on the paper picker. This equipment reduce manual handling and realizes a process of automation.

Keywords: DA200, paper picker equipment

1. Introduction:

The paper picker is an automatic equipment for the cutting process in the automatic cutting production line. It can quickly take out the paper pile of set height from the placed paper pile to the work surface for cutting or subsequent processes. The paper picker can greatly reduce the labor intensity of workers and improve production efficiency. Although paper picker machine appear in the market as new equipment, with the advancement of the industrial automation revolution,it bound to be widely used in the production process of printing or packaging.

At present, most of the paper pickers on the market use rollers to insert the paper picking mechanism, that is, a rotatable rubber rubber roller is installed at the front end of the worktable, and the rollers are used to squeeze directly into the stack of paper to pick up the paper.

* High requirements for paper, generally only thick paper or packaging cardboard with a weight of more than 200 grams per square meter can be used. Because this roller-inserted paper picking mechanism uses the principle of directly squeezing into the paper stack, the rubber roller needs to be directly squeezed into the paper stack during the paper picking process, and then the friction force of the rubber roller is used to lift the paper stack to the working table.For paper or special paper weighing less than 200 grams per square, the squeezing of the rubber roller will directly cause the paper to curl or be damaged.

* The paper pickup height is low, and the paper pickup height can be adjusted each time. Because the roller-inserted paper picking mechanism needs to directly squeeze the paper stack from the front, if the paper picking height is too high each time, the friction of the paper stack will increase, and it is difficult for the rubber roller to squeeze the paper stack. The next process of taking paper is generally cutting. Generally, the cutting width of a paper cutter is 160mm, and the height of paper taking is usually between 120mm and 140mm.

* The neatness of paper picking is not very demanding, and it usually needs secondary finishing when cutting.

* The paper picker has a simple structure and low cost. In order to obtain a better paper picking effect, this kind of paper picker often adds a lot of complicated auxiliary mechanisms, such as a paper press set at the back of the paper stack when the roller is inserted to prevent the paper stack from shifting or used to drag the paper stack on. The clamping robot arm of the tabletop, etc.

* The paper picker has high efficiency, low failure rate, and occasional paper damage. Because the paper is lifted by the direct squeeze of the roller, the paper characteristics are required. If the rubber roller cannot be inserted or the friction is too large after insertion, the roller jam or the workbench cannot be inserted, etc., resulting in damage to the paper stack Or the machine fails and shuts down.

Fugure 1. Equipment scene application picture

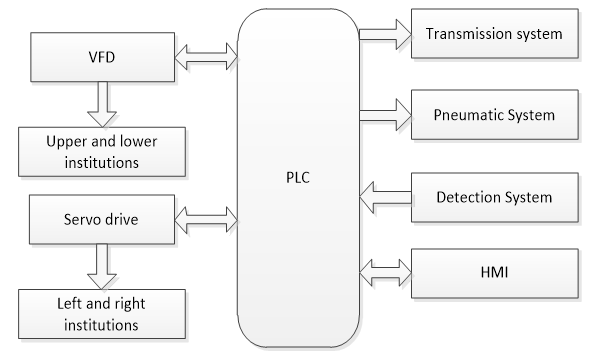

Figure 2. paper picker eqeuipment control system

2. Control requirements

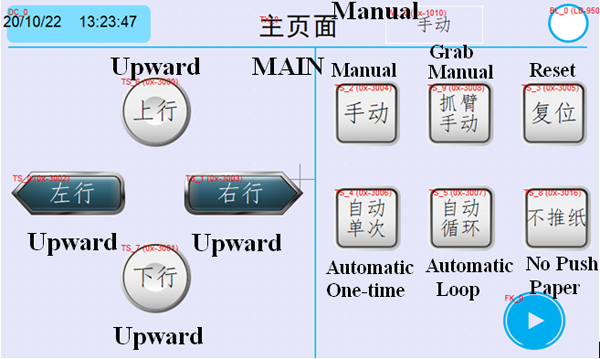

Figure 3. HMI interface

Customer requires the servo to move left and right, use the position mode, and at the same time have a soft stroke of acceleration and deceleration;

In manual operation, the operating mechanism can be jog, and no impact occurs;

In the automatic mode, the mechanism can be run to the specified position, and at the same time, there is no impact occurs;

Reset, let the whole mechanism reset to the initial state, and automatically wait for the state of preparation;

3. DA200 introduction

SV-DA200 series products adopt modular structure and are a series of servo drives with rich functions and powerful performance. The upper computer software adopts USB communication, and the bus control can be Modbus bus, CANopen bus, EtherCAT bus, MotionNet bus, and PROFIBUS-DP bus can be selected through expansion card. At the same time, the product has online/offline inertia identification, gain switching, automatic/manual notch filter, automatic/manual vibration damping filter, internal point-to-point control, full closed loop control, safety terminal STO, and supports multiple types of encoders , 16-bit analog input and other functions, the application is more flexible and the performance is more stable; other characteristic parameters and functions are shown in the following table 1:

Control mode | 1. Position control; | |||

Function | Position control | Control input | 1. Retaining pulse clearance; 2. Command pulse input disabled; 3. Command frequency division/doubling switching; 4. Vibration control switching | |

Control output | Position complete output | |||

Pulse input | Max. pulse | Photoelectric coupling: differential input 4Mpps, open collector input | ||

4. Parameter debugging

The whole system is commanded by the controller to the servo. The DA200 series servo has excellent performance in position mode control.

The key parameters of the servo are shown in Table 2.

P0.03 | Control mode selection | 0:Position mode | 0~9 | 0 |

P0.20 | Position command | 0:Pulse input | 0~4 | 0 |

P0.23 | Pulse input form | 0:Pulse + mode | 0~2 | 0 |

P0.26 | Denominator of the | 1~(231-1) | 2000 |

Table 2: DA200 parameter setting table

5. Summary

The paper picker equipment reduces the labor force, speeds up the fluency of the printing front end operation, greatly improves the work efficiency, and is worthy of promotion.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.