Background & Requirement

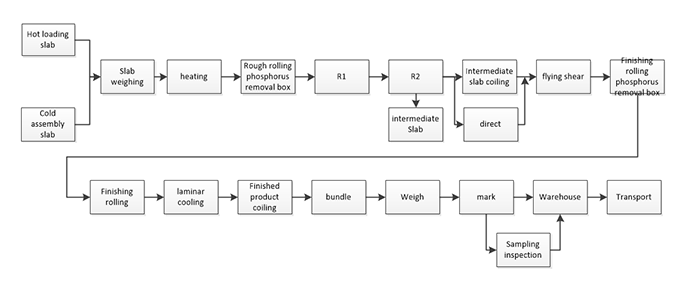

The hot rolling production line of a steel company has been designed with annual output of 5 million tons. The main products are various plain carbon steel, high-quality carbon steel, low alloy steel, shipbuilding steel, spiral welded pipe and other steel coils with σb≤800N/mm2.

The VFD used in the production line have been out of production for many years, and the spare parts supply cycle is long and there also has a risk of supply interruption, which brings major hidden dangers to production security. A high-reliability and high-performance domestic transmission product is needed to achieve seamless replacement to ensure the stable operation of the equipment.

INVT solution

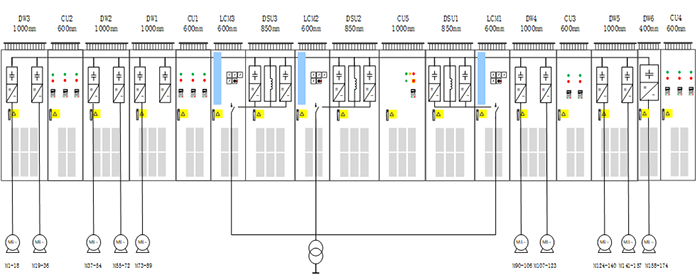

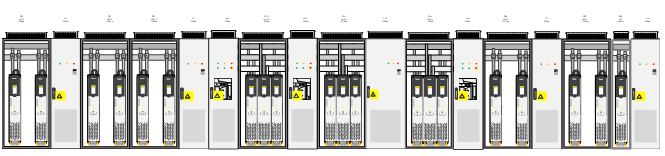

INVT has formulated a transformation plan based on the actual needs of customers, using INVT GD800 series engineering transmission VFD to replace the original rolling line 380V sixth section transmission cabinets and 1-5 group cold roller table transmission cabinets, with a total of 17 cabinets. Communicating with the host computer TDC system through Profibus-DP, the GD800 inverter adopts seamless replacement software and is fully compatible with the DP communication protocol of the original inverter without modifying the TDC system.

* System topology diagram:

* System layout diagram:

Customer benefits

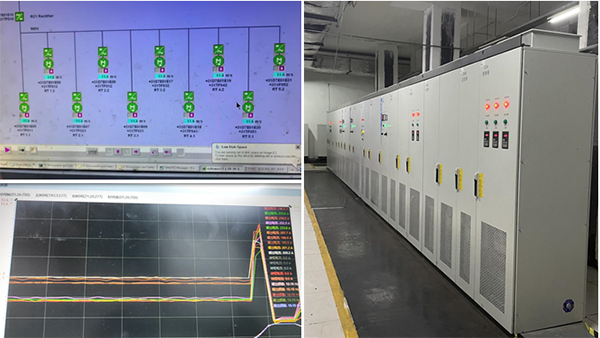

INVT completed the protective dismantling of the original cabinet, installation of new cabinets, electrical construction, and equipment debugging within 8 days. The equipment operation met the production process requirements and was put into production on time.

1. INVT helped a company complete its first transmission localization project for its hot-rolling production line.

2. INVT solution has good compatibility and stability, which can effectively reduce high energy consumption and maintenance costs;

3. Real-time detection and diagnosis to ensure safe and continuous operation of the system;

4. INVT’s technical team responds quickly and provides reliable guarantee for on-site equipment debugging and after-sales service.

Summarize

In addition to this project, INVT has cooperated closely with a steel company on multiple products and projects, including lime kiln/rotary kiln, comprehensive utilization of waste heat recovery at public facilities, dry quenching coke silo for in-plant transportation, etc. Won the Excellent Supplier Award from the Steel Company.

INVT has been deeply involved in the steel industry for 21 years. Relying on its accumulated technical advantages, high-performance products and complete after-sales services, INVT has achieved stable operation of equipment, serving the sintering, pelletizing, ironmaking, steelmaking, steel rolling and acid production of the steel industry. Washing and other process sections have been continuously recognized by high-end major customers.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.