Abstract: Oval type automatic Screen printing machine is based on rotary screen printing machines, its performance and printing process is very well. The machine adopts modular design, high-strength aluminum alloy structure, the main rotation system adopt high-precision servo drive to assure the fast and stable operation, with the features of accurate printing, reliable performance, easy operation. Suitable for water-based ink, plastisol ink, Solvent ink and other printing processes, standardly configurated with flocking function. It's best for pieces and various garment printing, and also flocking processing.

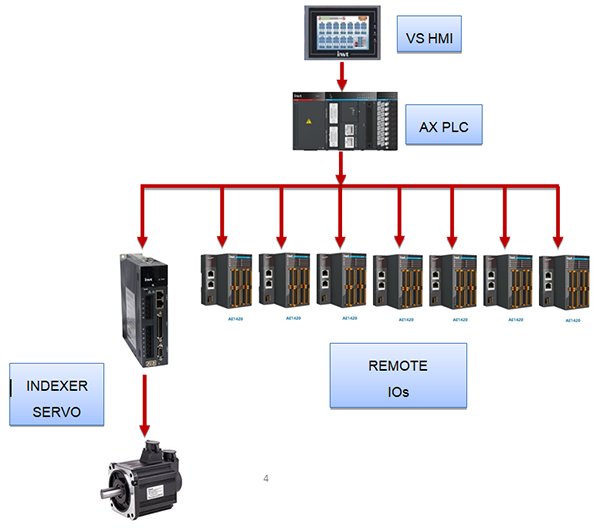

Keywords: AX PLC, Ether CAT, Remote IOs, VS HMI, DA200, AE1420

1. Introduction

Machine Procedure:

* Control system:

1. HMI interface and PLC system ,self-diagnosis and printing station control

2. Real-time display of production speed to more clearly control the operating costs.

3. Different operation modes: Flood and squeegee mode with lift, Flood and squeegee mode without lift ,Print flash Print mode,automatic cycle, single cycle.

4. Each station can be controlled individually and be operated work or stop easily, also can control the entire equipment ON/OFF.

5. The speed and pressure of squeegee is independently adjustable.

6. Flood bar and squeegee can be fixed and took off without any tools and speed can be control by change the frequency of VFD.

7. The stop position of print head can be set freely with adjust of sensor.

8. AC drive system, stepless speed regulation.

9. Screw adjust position, accuracy±0.05mm

10. Printing times and route can be set free in HMI as per requirements

* Rotating System:

1. Servo motor drive, running precise, high-speed, stable running of panel in rotary movement

2. Forward and reverse of machine as per print loading and unloading and reverse the station number logic is also possible in this machine.

* Module Expansion:

1. Customers buy the printing machine with the suitable numbers of stations according to demand. For further needs,you can quickly and easily enlarge the machine in every two-station units.

2. Project information and Solution

2.1 Project information

Site information: Garments company

2.2 INVT solution

Product | Model no. | Qty | Application |

PLC | AX72C-1608N | 1 | CONTROLLER |

HMI | VS102HCS | 1 | CONTROLLER |

REMOTE IOs | AE1420 | 7 | MODULE |

SERVO MOTOR | SV-DA200-2R0E-2-1A0-1000 | 1 | PALLET INDEXER |

SERVO DRIVE | SV-DA200-2R0-2-N0 | 1 | PALLET INDEXER |

2.3 System Configuration:

2.4 System commissioning

Control panels

3. Advantages and benefits

1. Highly versatile. Each printing head is completely independent and can

be individually programmed.

2. Easy programming and program store with the digital touch screen.

3. Pallet automatic levelling system: pallets are automatically identically

4. levelled in height and in horizontal achieving a perfect printing accuracy

+- 0.5mm.

5. The working pressure of each squeegee can be adjusted independently.

Self-aligning and tilt-adjustable squeegees.

6. Digital control of squeegee speed: from 0.15 to 1.5 m/sec.

7. Double centring device located on each head for greater fitting precision.

8. Extremely accurate micrometric system that facilitates design changes

and fitting.

9. Innovative system of pallets free, easy to change in seconds without

tools.

10. Operators accessibility. Prevents operator fatigue and improve the

productivity. Machine speed is 746 t-shirts per minute of 55 pallet machine

11. Intermediate areas for pre-drying.

4. Conclusion

This T-shirt/screen printing machine is installed in garment industry and performance, accuracy and stability all meet the process requirement. We have given INVT solution against Omron and Mitsubishi controller.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.