1. Introduction

The solvent-free compound machine is a device that uses solvent-free adhesives to bond two or more substrates together. It originated from the European technology and has the characteristics of safety, environmental protection, hygiene, high efficiency, and energy saving. Therefore, this equipment is suitable for wide range, especially in the field of food and pharmaceutical packaging.

2. Customer requirement

In a packaging machinery and equipment company in Jiangsu, the customer's solvent-free laminating machine is a two-layer laminating machine with a single-station winding and unwinding structure.

The following requirements were put forward for the control system of this equipment:

Constant tension control; high control precision; high response speed; improve overall efficiency; save cabinet space

Equipment diagram

3. INVT solution

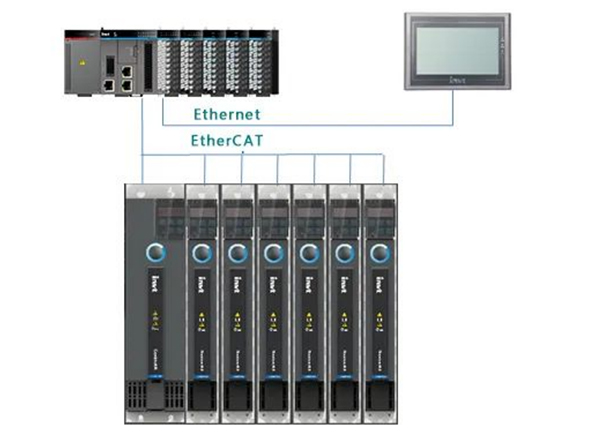

In response to the above needs of customers, INVT provides customers with a system solution of HMI+ AX series programmable controller + Goodrive600 series high-performance multi-drive VFD. This solution has the characteristics of excellent tension control performance, fast response speed, high integration and beautiful wiring, etc.

System solution diagram

AX series product features:

● The controller is programmed with ST high-level language, and the programming and debugging efficiency is high

● EtherCAT bus control, fast response, improved process effect again.

● Built-in process package, complex control, simplified.。

Goodrive600 product features:

● High speed control accuracy: open-loop application can reach ±0.2%, closed-loop application can reach ±0.02%.

● The book-type module design of equal height and depth supports multiple side-by-side close-fitting installations, saving cabinet space.

● The common DC bus scheme realizes the internal flow of energy, improves the power efficiency of the system, and realizes energy saving.

● Fast integration: Quickly connect the DC bus-bar design, fast parallel operation, and save wiring man-hours and costs.值

4. Customer value

01 Energy saving up to 20%

The internal flow of energy is realized through the common DC bus scheme, which saves more than 20% of the energy compared with the conventional scheme.

02 Overall efficiency increased by 30%

EtherCAT high-speed industrial bus communication is adopted, which perfectly realizes the stable output of tension and speed, and can be adjusted in real time, increasing the winding and unwinding speed by 30%.

03 Save 40% of cabinet space

Goodrive600 series VFD are installed close to each other, which saves 40% of the cabinet space compared with conventional VFD.

04 Stable and precise

● The winding tension is stable, and the winding material does not deviate.

●The overall line speed is stable and will not cause material loosening or stretching.

● The target value of unwinding tension can be changed in real time according to the change of roll diameter.

● The traction roller can adjust the feeding speed and frequency in real time, and the material will not stretch or loosen.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.