Abstract: This paper mainly presents the INVT IVC3 series PLC and DA200 servo drive used to carve the stone with a sandblasting machine with the help of 3-axis motion. In this project, HMI is used for data feeding and monitoring of the process.

Keywords: IVC3 PLC, HMI, DA200 servo drive, CNC sandblasting machine, 3-axis motion, RS485 communication.

1. Introduction

The major parts of the machine are 4 servos, ICV3 plc, and HMI.

* 3-Axis motion: The system for 3-axis motion consists of four servos. The bed forms the foundation of the entire system. To position the stone, a bed is utilized. Three axes of motion are used to move the working nozzle. Z-axis (up-down) travel is handled by one servo, Y-axis (long travel) by two servos, and X-axis (short travel) by one servo.

* PLC and HMI: PLC is utilized in this application to manage the entire machine application. Marking points, monitoring, cycle start/stop, manual operation, system settings, parameter adjustments, and user-defined activities are all done with HMI. HMI and PLC are in communication via RS485 protocol.

* Process: This is a representation of stone sandblasting using a CNC machine. Stones are initially placed on the bed. Next, the teaching point technique is used to define the squares of stone which is need to be sandblast. The auto-cycle begins after teaching is finished. After reaching the starting place, the nozzle moves to the stone's surface (every operation needs to insert of the stone's thickness). Stone is being sandblasting. Nozzle travels to its home position once the entire specified operation (no of repeat cycle and no of block) has been completed. With the input of block number, we can operate the machine.

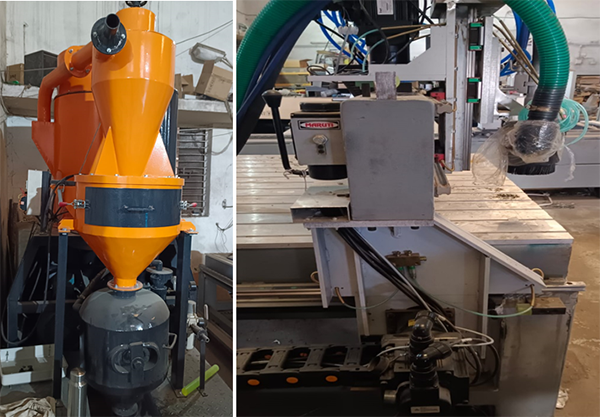

Figure – Auto sabndblastic CNC machine front view

2. Project information and Solution

Figure – Sandblastic mechanism and Machine side view

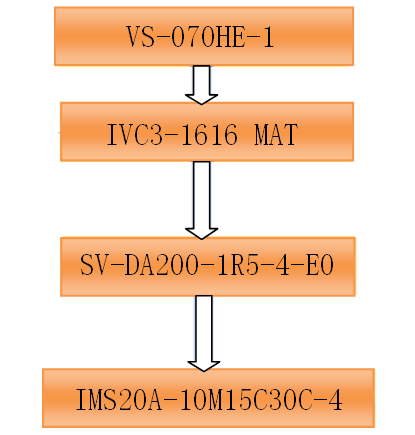

Figure – Machine flow chart with simple block diagram

2.1 Project information

1. In this application sandblast large stone in single cycle

2. PLC: IVC3-1616MAT transistor outputs type PLC used for process execution

3. Here 1.5kw servo used for 3-axis motion.

4. Different size, thickness and patterns of stones.

5. Auto homing after cycle complete and monitoring of system via HMI, with block number we can operate the system.

6. In PLC we have 50 blocks of range has been given and speed of sandblasting and nozzle up down settings as per stone thickness given.

2.2 INVT solution

Product | Specification/Model | Quantity |

PLC | IVC3-1616MAT | 1 |

HMI | VS-070HE-1 | 1 |

Servo Drive | SV-DA200-1R5-4-E0 | 4 |

Servo Motor | IMS20A-10M15C30C-4 | 4 |

3. System commissioning

Figure – Machine front view and HMI setups

Figure – Panel photo and mechanical setup for servo as well as induction motors

4. Advantages and benefits

1. In recent scenario these industries are working in handy mode or manual operation mode. by using automation, we made work fast and very precise.

2. This solution is cost effective and easily we can implement where cost issue compares to Delta, Schneider, and other make automation system

3. We can achieve equal performance over larger size of stones.

4. PLC and servo execution through pulse and communication mode as per requirements of operations.

5. Conclusion

As per study and application execution, these industries are recently working in manual or handy mode. So, we achieved result through implementation of simple cost-effective model of IVC series PLC and servo system. This application very useful for small and large industrial product manufacturing.

6. Future Scope

In this application we execute our system with 3 axis servo system with pulse mode. These types of application are popular and we provide best solution with minimum price. This type of system we can implement in many industries.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.