1. Project background

The single wire cutting machine adopts the way of reciprocating cycle movement of diamond wire to form a relative grinding motion between diamond wire and the object to be cut, so as to achieve the purpose of cutting; Single wire cutting machine is widely used to cut a variety of metal and non-metallic composite materials. Especially in cutting material with high hardness and high value, it shows rolling advantages over traditional mortar cutting. It can improve the processing speed several times, and significantly reduce material consumption, which makes the production process more environmentally friendly.

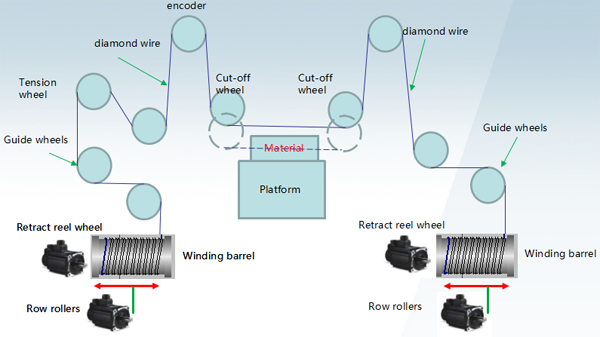

2. Principle of equipment

The single wire cutting machine adopts two winding cylinders, which move back and forth to drive the steel wire to realize cutting processing on the machined parts;

Principle of equipment

1) The use of servo hand wire collection, according to the automatic calculation of the discharge coil diameter and the set cutting speed to obtain the instruction speed of the discharge line, to ensure that the wire collection speed is constant, to achieve the perfect line effect;

2) Two lifting servos couple the virtual axis through the speed, the virtual axis and then go down a feed speed, and then through the superposition instruction to achieve the up and down swing cutting function and synchronous cutting function;

3) The swing rod shaft is controlled by torque, and a constant tension is applied to the line to keep the tension of the line constant;

4) Servo wiring releasing is adopted, and the wiring releasing command speed is obtained according to the automatically calculated setting out coil diameter and PID;

5) Through the cam function, the winding wheel can follow the winding motor to run, so that the winding wheel can rotate one circle, and the winding servo takes a set winding spacing;

6) The function of automatic deviation correction is realized by using the deviation correction photoelectric on both sides;

3. Customer needs

1) To meet the efficiency of processing, the line speed up to 18M/ S;

2) The line tension is stable, and the line is constantly in operation;

3) It can be run after power on, without complex parameter settings;

4) The line length is calculated accurately to avoid wireless downtime and waste of processing wire;

4. INVT Solution

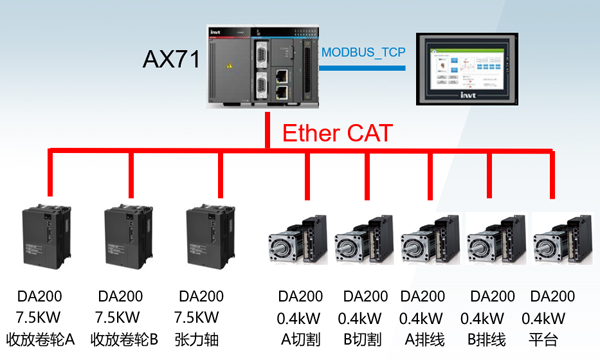

INVT introduces a wire cutting solution based on VS+AX71+DA200, where the medium PLC AX71 controls servo drives synchronously via the EtherCAT bus. AX71 PLC connects with touch screen through Ethernet communication, 100M high-speed communication speed makes the touch screen interactive use more smooth;

Scheme topology diagram

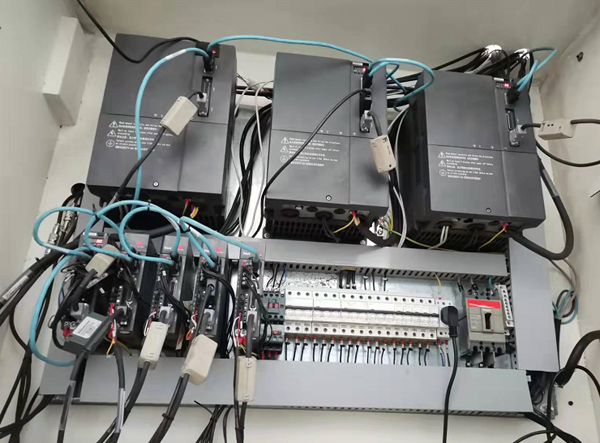

On-site electrical cabinet diagram

Scheme configuration table

Product | Model | Qty.. | Mark |

PLC | AX71-C-1608N | 1 | PLC CPU |

Power module | AX-PWR | 1 | Power supply module |

Servo drive | SV-DA200-0R4-2-N0 | 5 | EtherCAT drive |

Servo motor | SV-MH06-0R4G-2-9A0-1000 | 3 | 400W no brake |

Servo motor | SV-MH06-0R4G-2-9A2-1000 | 2 | 400W with brake |

Servo drive | SV-DA200-7R5-4-N0 | 3 | EtherCAT drive |

Servo motor | SV-SM18-7R5B-4-9A0-1000 | 2 | 7500W no brake |

Servo motor | SV-SM18-7R5B-4-9A4-1000 | 1 | 7500W with brake |

HMI | VS-102HCS | 1 | 10.2’’ |

5. Characteristics of the program

1) automatic calculation of coil diameter: the program uses an encoder, automatically calculate the diameter of the wire collection roller and the release roller, the coil diameter accurately ensures the stability of the line speed, reduce the requirements for workers;

2) Automatic deviation correction of the line: through the correction photoelectric, when the line shaft deviates, it realizes automatic correction and realizes automatic operation;

3) The tension is stable, the tension arm fluctuation is small, and the broken diamond wire and the smoothing of the processing surface are avoided;

4) After-sales maintenance: less wiring, easy troubleshooting. The program structure is concise, and the motion control function block omits a lot of calculation work of the small programming PLC, which is convenient for customers to change and maintain;

5) Support a variety of cutting methods: multi-stage speed cutting - swing cutting - synchronous cutting, free switching of various cutting methods, smooth transition, smooth processing surface, better product effect.

6. Customer value

INVT single wire cutting machine control system program fully meets customer needs, through the bus control, customers do not need complex wiring. It adopts 23-bit multi-turn absolute value encoder motor and PID control in the system, and it can run directly after power on and no need for complex operation. VS touch screen designs the interactive interface according to the terminal operation habit, which fully meets the performance requirements of similar products; The customer is very satisfied with the commissioning effect in terms of efficiency and accuracy, and sends it to the end customer's site for acceptance.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.